Research Article, J Polym Sci Appl Vol: 9 Issue: 1

Development of Paper from Luffa/ Cotton Fibre Blend

Nqobizitha Ndebele*, Hassan Moyo, Lindani Ncube, Mufaro Moyo, Lloyd Ndlovu, Peeps Gonde and Sizo Ncube

Department of Fibre and Polymer Materials Engineering, National University of Science and Technology, Bulawayo, Zimbabwe

*Corresponding Author: Nqobizitha Ndebele, Department of Fibre and Polymer Materials Engineering, National University of Science and Technology, Bulawayo, Zimbabwe

E-mail: nqobizitha.ndebele@nust.ac.zw

Received date: 15 May, 2024, Manuscript No. JPSA-24-135114;

Editor assigned date: 20 May, 2024, PreQC No. JPSA-24-135114 (PQ);

Reviewed date: 04 June, 2024, QC No. JPSA-24-135114;

Revised date: 10 March, 2025, Manuscript No. JPSA-24-135114 (R);

Published date: 17 March, 2025, DOI: 10.4172/Jpsa.1000155

Citation: Ndebele N, Moyo H, Ncube L, Moyo M, Ndlovu L, et al. (2025) Development of Paper from Luffa/Cotton Fibre Blend. J Polym Sci Appl 9:1.

Abstract

The increased awareness of the environmental impact posed by rampant destruction of trees for paper manufacturing has driven many paper and pulp mills to seek for alternative raw material sources, particularly plant fibres. The pulp and paper industry is ranked as the third most polluting industry in the world and as such, over the years more research has been conducted worldwide in a bid to curb its effects. This research was rooted on the development of paper from a blend of luffa sponge plant fibre and cotton plant fibre as an alternative to the wood fibres so as to reduce the rate of deforestation. Luffa and cotton fibres were independently pulped, bleached, and refined before being blended prior to paper sheet formation. Soda pulping process using sodium hydroxide was used to delignify the fibres while hydrogen peroxide was used for bleaching. The treated fibres were then independently refined and sieved so as to obtain uniform pulp consistency. Paper sheets were the produced from blending fibres together in luffa-cotton ratios of, 0:100; 20:80; 40:60; 50:50; 60:40; 80:20 and 100:0. Several tests were carried out on the resultant papers so as to compare their properties with that of the standard paper already in the market. The results indicated that an increase in the luffa fibre proportion in the luffa/cotton fibre blend produced paper whose properties were comparable to, and in most cases, exceeded that of standard certificate paper. From the experimental test results, it was concluded that a 50:50 ratio of luffa/cotton fibre blend produced paper with optimum values of grammage, thickness, tensile strength, bursting strength, opacity and brightness.

Keywords: Luffa fibres; Cotton fibres; Pulp; Paper; Blend; Paper properties

Introduction

The paper industry plays a considerable role in the growth and sustenance of the economy of any country. Regardless of the increase in computerization, paper and its products are still used extensively in offices, academic institutions, industries and households to relay information, contain precious products and for sanitization. Wood and non-wood fibre sources which contain cellulose can be used individually or as blends to produce paper. Generally, wood fibres are the main raw materials used for paper production. These cellulose-rich fibres undergo a series of papermaking processes such as pulping, refining, bleaching, wet laying, and drying before being tested for conformity to standards.

Paper is the best raw material used in the production of scaffolds used in tissue engineering as it is both sufficiently rigid and biodegradable. It is used to make important documents such as passports, certificates, money, among many other applications due to its ability to be engineered to meet pre-determined specifications. As such, the paper industry is expected to reach about USD680 billion by the year 2027, at a compound annual growth rate of 3.45% [1]. This global rise would result in the destruction of forests, which ultimately leads to global warming.

In a bid to curb deforestation, desertification and global warming induced by increased wood cellulose fibre demand, China and India have established vibrant non-wood pulp and paper mills. Additionally, these countries have land specifically allocated to support and provide a life-line for these mills [2]. Non-wood fibres have reportedly been found to produce excellent paper when used alone or when blended with other non-wood and wood fibres [3].

In this study, a number of paper specimens were produced from different blends of non-wood fibres namely cotton and luffa fibres. These paper specimens had their properties compared with that of a specialty paper, already in the market. The luffa plant is a rapidly growing vine reaching maturity in four months [4]. This species of the Cucurbitaceae family is characterised by hollow stems, large leaves and broad root system and is native to the African continent [5]. It is traditionally grown on a small scale basis in homesteads for use particularly as a scrubber. Cotton is widely cultivated in Africa and beyond, with countries like Zimbabwe and South Africa exporting quantities worth US$30.08 million and US$43.66 million in 2020, respectively [6,7]. Both luffa and cotton fibres are light weight, biodegradable, non-poisonous, environmentally friendly, with stable chemical and physical properties [8]. Luffa and cotton fibre yield is 10 and 15 tonnes per hectare respectively. Also, biodiesel can be obtained upon crushing these plants’ seeds, and the residual material can be used as feedstock [9].

Studies have shown that paper made from luffa fibres can possess excellent optical, physical and mechanical features [8]. In addition, cotton fibres have always been the most preferred raw material in the production of high grade specialty paper for ages, being suitable in the production of bank notes, certificates and passports, among others. This is attributed to high cellulose content, high strength to weight ratio, high thermal stability and virtually no lignin [10,11]. A blend of these non-wood fibres is thus proposed to yield a good quality paper.

Materials and Methods

Materials

In this study, luffa and cotton fibres were the primary materials of interest. Other materials used are shown in Table 1.

Raw material preparation

Luffa plant gourds from a local farm were soaked in warm water for 20 minutes until the sponges slipped out of the skins. A sharp blade was used to rip open the sponges so as to liberate the seeds enclosed therein. The sponges were then soaked in hydrogen peroxide for 10 minutes [12]. Clean carded cotton fibres were obtained from a local ginnery.

Pulping

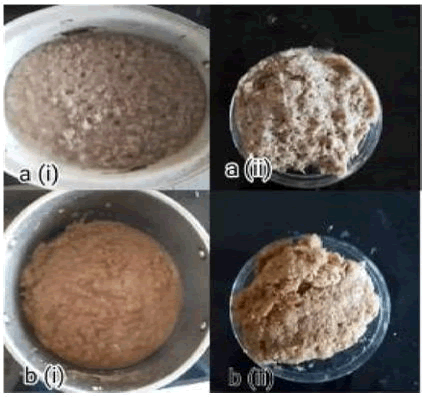

All the pulping experiments in this study were conducted using a laboratory-based digester, which is basically a large pressure vessel which is heated via a hot plate. The luffa fibres as well as the cotton fibres, were independently pulped for a period of 90 minutes at 90°C, using analytical grade Sodium Hydroxide (NaOH) of 99.9% concentration. This is a typical Soda Pulping Process. The resultant pulp batches were subsequently washed with distilled water before being stored in pulp bins, awaiting the next process (Figure 1).

Figure 1: Cotton fibres before a) (i) and after pulping a) (ii); and the luffa fibres before b) (i) and after pulping b) (ii).

Bleaching

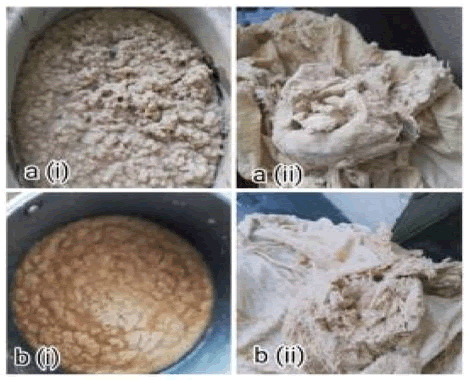

Bleaching was also conducted using the digester heated to a steady temperature of 60°C for 90 minutes, in Hydrogen Peroxide (H2O2) (Figure 2).

Figure 2: Cotton fibres before a) (i) and after bleaching a) (ii); and the luffa fibres before b) (i) and after bleaching b) (ii).

Refining

All the refining experiments were conducted using a mortar and pestle system. After the refining process, the pulp was passed through a fine sieve to obtain fibres of high consistency and uniform dimensions. The mesh size of the sieve used was 200, with 0.075 mm hole diameter. The sieved pulp, was then stored in airtight containers while the rest was sent back for further refining until all the pulp had attained high fineness and consistency. The average pulp consistency obtained after the refining process was found to be 30%.

Blending

The refined luffa fibre pulp and cotton fibre pulp were then blended in luffa fibre to cotton fibre ratios as shown in Table 1.

| Sample no. | Code | Luffa (%) | Cotton (%) |

| 1 | SP1 | 0 | 100 |

| 2 | SP2 | 20 | 80 |

| 3 | SP3 | 40 | 60 |

| 4 | SP4 | 50 | 50 |

| 5 | SP5 | 60 | 40 |

| 6 | SP6 | 80 | 20 |

| 7 | SP7 | 100 | 0 |

Table 1: Paper specimens used in the experiment and their corresponding luffa/cotton ratios.

The physical and chemical properties of cotton and luffa fibres are show in Table 2.

| Property | Cotton | Luffa |

| Cellulose (%) | 96.0 ± 0.3 | 63.0 ± 2.5 |

| Lignin (%) | 0 | 11.69 ± 1.2 |

| Hemicelluloses (%) | 3.0 ± 0.2 | 20.88 ± 1.4 |

| Ash (%) | 1.3 ± 0.1 | 0.40 ± 0.1 |

| Length (mm) | 65 ± 0.1 | 0.90 ± 0.1 |

| Density (gm/cc) | 1.52 ± 0.1 | 0.92 ± 0.1 |

| Diameter (µm) | 22 ± 1.0 | 12 ± 2.0 |

| Crystallinity (%) | 87 | 69 |

Table 2: Physical and chemical properties of cotton and luffa fibres.

Papermaking

The blended cotton/luffa fibre pulp was then converted into 115 g/m² handsheets using a frame and basin wet layup process. The very additives incorporated in the manufacturing process of the control paper, which is the specialty paper already in the market, were blended with the pulp. These additives are displayed in Table 3.

| Chemical | Purpose |

| Titanium dioxide | Optical brightener |

| China clay | Filler |

| Alkyl ketene dimer | Sizing agent |

| Calcium carbonate | Retention agent |

| Urea formaldehyde | Wet strength agent |

| Polyacrylamide | Dry strength agent |

Table 3: Additives used in the experiments.

Paper testing

The control paper (C.P) was produced from a blend of cotton (60%) and sisal (40%) fibres. All the paper specimens were conditioned (ISO 187) prior to being subjected to a series of standard tests, namely: Tensile strength (ISO 1924-2), Bursting strength (ISO 2758), Opacity (ISO 2471:2008), Brightness (ISO 2470-2), Moisture Content (ISO 287) and Water Absorption (ISO 535).

Results and Discussion

Grammage

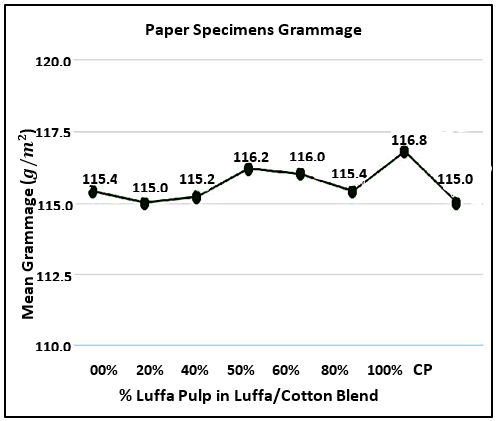

Grammage is the mass per unit area of a sheet of paper, usually expressed as grammes per square meter (gsm or g/m2). A papermaker always strives to obtain all desired paper properties with minimum possible grammage to ensure profitability. Paper is sold by weight although the buyer is interested in area of paper. The grammage is what determines how much area the buyer gets for a given weight (Figure 3) [12].

Figure 3: Variation of paper grammage with luffa-cotton fibre pulp content.

The tighter the grammage range, the more efficient will be the machine operation during mass production. Figure 3 shows the lowest mean grammage value was 115.0 g/m² (SP2 and C.P) while the highest was 116.8 g/m² (SP7). The range of grammage values obtained from the experiments (115.0-116.8 g/m²) was within the theoretically accepted grammage range of 25-400 g/m² values for paper to exhibit excellent printing quality. As such, the experimental values indicate that during the printing process the ink would permeate into the cellulose substrate without leaking. This grammage also enhances the opacity of the paper, as well as the strength and flexibility of the resultant paper. Generally, the 110-120 gsm range provides both optimum paper strength and lightweight properties.

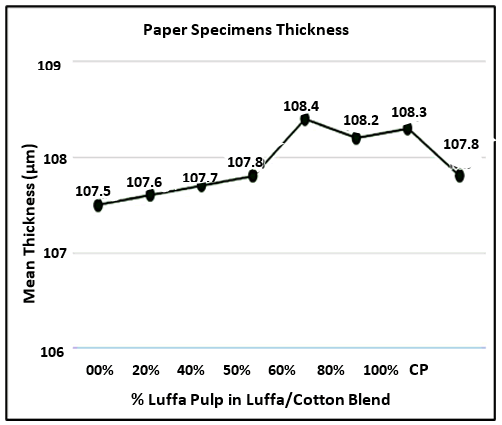

Caliper

Paper thickness is the distance between two successive sides of a given page, and is also referred to as caliper. Basic paper features such as brightness and strength are not adversely affected when there is minimal variation in the caliper. In paper industries, uniform paper caliper is essential for excellent roll building as well as the subsequent printing (Figure 4).

Figure 4: Variation of paper caliper with luffa/cotton fibre pulp content.

The experimental results show that the caliper (thickness) of the paper specimens used was within the range 107.5-108.4 μm. The highest caliper recorded (108.4 μm) was for specimen SP5, while the lowest (107.5 μm) was for specimen SP1. The caliper is relatively low for this grammage range, as shown in Figure 4, which indicates that the pulp used in making the paper specimens was well refined. Generally, the lower the thickness value of a paper specimen for a given basis weight the highly filled it is. Therefore, the variation in caliper among the luffa/cotton fibre specimens is a clear indication that these paper hand sheets were well laid.

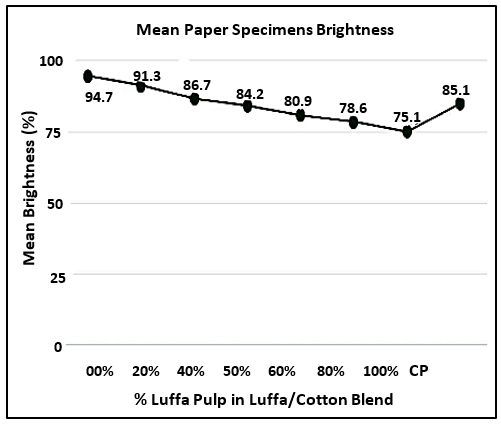

Brightness

Brightness is the amount of light reflected by a sheet of paper. Generally, paper brightness is regarded as an important aesthetic property because the brighter the paper, the more desirable it is to customers. The highest mean brightness value (94.7%) was recorded from SP1, while the lowest value (75.05%) corresponded to SP7. The mean brightness value of SP4 (84.22%) was found to be comparable to that of C.P (85.05%).

Figure 5 shows a decreasing trend in the paper specimens’ percentage brightness as the proportion of luffa fibres decrease. In other words, as the proportion of cotton fibres in the paper specimen’s increases, the brightness also increases. This is because, cotton fibres have less lignin content compared to luffa fibres, thereby making them display a whiter shade before and after bleaching (Figure 2a). In fact, cotton is almost pure cellulose, and so, paper whiteness is expected to increase as the proportion of cotton fibres is increased. It is noteworthy that these results are within the accepted theoretical range of paper whiteness for certificates, that is, between 70 and 100% [13].

Figure 5: Variation of paper brightness with luffa/cotton fibre pulp content.

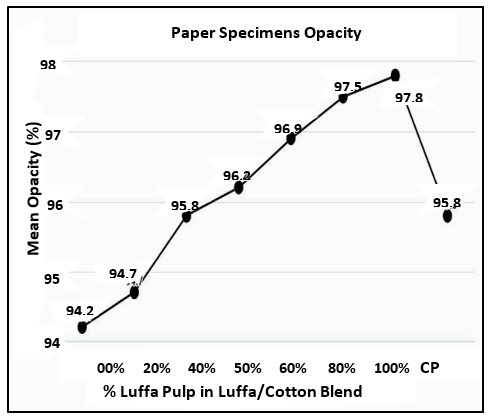

Opacity

Opacity is the measure of the amount visible light restricted from passing through a sheet of paper. It is the amount of show-through in paper and is very important in book printing because it affects how much the back side of a page shows through to the front, and how one page shows through to another. Paper opacity is generally increased by increasing the quantity of short fibres in the pulp, resulting in reduced levels of show-through in the paper (Figure 6) [12].

Figure 6: Variation of paper opacity with luffa/cotton fibre pulp content.

The highest average opacity value recorded was 97.8% while the lowest was 94.2% and these values corresponded to SP7 and SP1, respectively. SP3 and C.P registered the same mean opacity value of 95.8%. There was an increase in paper diffuse opacity as the percentage of luffa fibres is increased in the paper samples, as shown in Figure 4. Although the least paper opacity was exhibited by SP1 (that is, 100% cotton specimen), it is still an excellent level of opacity essential for printing purposes [12].

Brightness value decreases while the opacity value increases as a result of the increase of luffa pulp in the luffa cotton fibre pulp mixture. The higher the opacity of a paper, the greater the level of restriction of visible light passage through that sample [14]. The bulk of the samples (with the exception of SP1 and SP2) have opacity values near to or above 96% opacity, which means that these samples are almost impervious to penetration of visible light. This shows that these samples exhibit almost no print-based show through on the sheet below or on their back side. The overall opacity of all the paper specimens was excellent as a result of the thickness of all the samples. Hence printing using bold type, heavy coverage and solid block colours, which is synonymous with certificate paper printing would not have any negative impact on the paper samples.

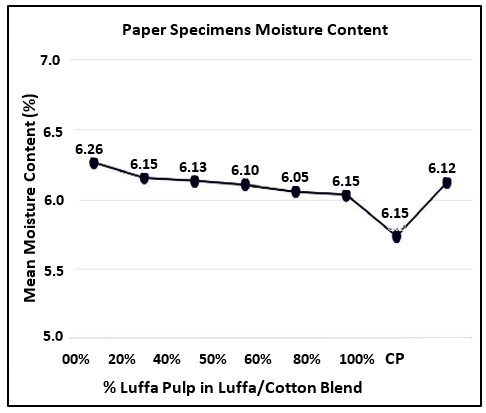

Moisture content

Paper moisture content is that measurable water quantity in a given paper. Cellulosic fibres have a high affinity for moisture, and hence their tendency to gain and lose moisture based on surrounding conditions has a bearing on the paper dimensions. Too much moisture content in paper makes its edges weak and wavy, while too little of it makes the edges hard and tight. Well refined pulp as well as inclusion of inorganic fillers, tend to keep the moisture content within the acceptable theoretical range of 5-7%, such that the ensuing paper sheet produced possesses excellent dimensional stability (Figure 7).

Figure 7: Variation of paper moisture content with luffa/cotton fibre pulp content.

The experimental results indicated a decreasing trend in the percentage moisture content of the paper specimens as the proportion of luffa fibres decreased. This meant that, as the proportion of cotton fibres in the paper increased, the percentage moisture content also increased. This is due to the fact that, cotton fibres, compared to luffa fibres, are inherently more hydrophilic than the latter. However, these results are within the accepted theoretical range of paper moisture content, that is, 5-7% [15]. Values outside this range would lead to degradation of physical, mechanical and chemical properties of paper. Most physical properties of paper undergo change as a result of variations in moisture content, for instance, the strength of paper decreases when moisture content rises above 7% or falls below 5%. Water has the effect of plasticizing the cellulose fiber and of relaxing and weakening the inter-fiber bonding. Too little moisture content in paper increases the brittleness of the fibres as well as excessive frictional heat, as they slide directly over each other, thereby greatly decreasing the paper strength. The electrical resistance and the dielectric constant of paper both vary with moisture content. The absorption and reflectance of certain bands of infrared and microwave radiation by paper are affected by its moisture content. Generally, as moisture content in paper increases, its ability to absorb and reflect radiation tends to increase and decrease, respectively [11].

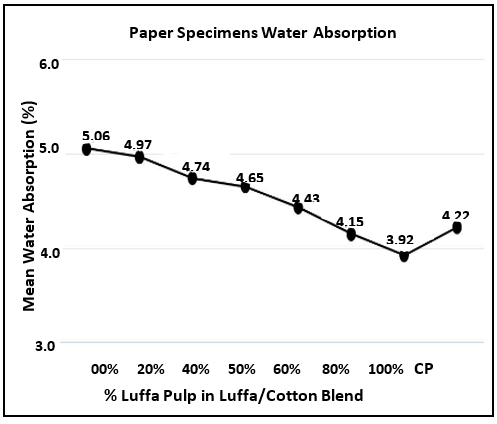

Water absorption

Water absorption is the amount of water absorbed by a paper material upon wetting its surface. Normally, water absorption in paper is affected, among other factors, by the type of cellulosic fibre used in making the paper. The higher the amount of cellulose in the fibres, the higher the rate of water absorption, since these fibres have an affinity for water.

The highest and lowest mean Cobb values recorded were 5.06% and 3.92%, corresponding to SP1 and SP7, respectively. With the exception of SP6 and SP7, all the paper specimens exhibited average Cobb values which were greater than that of C.P. Results obtained from the Cobb test. Figure 8 shows a decreasing trend in the rate of water absorption as the proportion of luffa fibres decreased. This is due to the fact that luffa fibres have less affinity for water compared to cotton fibres. However, since both these fibres are cellulosic in nature, they contain active sites for bonding with the hydroxyl group which is in water molecules. These Cobb results are within the accepted theoretical range of paper water absorption, which lies between 3-6%. Any values outside this range would lead to degradation of physical, mechanical and chemical properties of paper [16].

Figure 8: Variation of paper water absorption with luffa/cotton fibre pulp content.

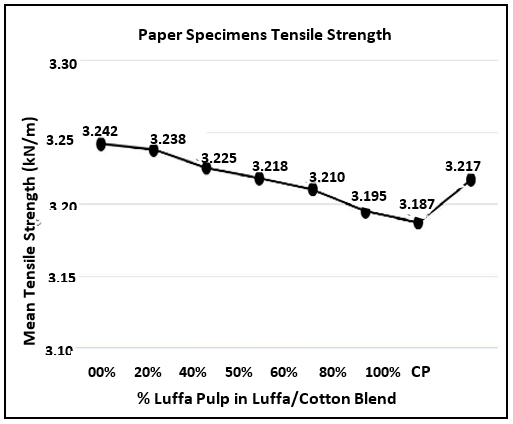

Tensile strength

Tensile strength of paper is the maximum amount of stress required to break a paper sheet strip. This parameter is a good reference point on the general performance of the paper during application. The tensile strength tends to increase in paper made from blended pulp fibres with the greater the quantity of long fibres in the blend. Results from the Tensile Tester shown in Figure 9 show decreasing tensile strength of the paper specimens as the proportion of luffa fibres decreased. The results ranged from 3.187 to 3.242 kN/m, with the lowest and highest mean tensile strengths corresponding to SP7 and SP1, respectively. Paper specimens SP1, SP2, SP3 and SP4 recorded mean tensile strength values which exceeded that of C.P. This was an expected observation, since cotton fibres, being inherently longer than luffa fibres allow for a greater degree of fibre entanglement in the paper. Also, refined cotton fibres contain more active sites for hydrogen bonding with hydroxyl group in water, as compared to refined luffa fibres because they are longer and have a higher cellulose content [4]. This means that greater tensile force is required to break the hydrogen bonds as well as the fibre entanglements, as the proportion of cotton fibre pulp increases. Hence, as the proportion of cotton fibres in the paper increases, the tensile strength of the paper also increases. These results are within the accepted theoretical tensile strength range of certificate paper, that is, 3-4 kN/m [17].

Figure 9: Variation of paper tensile strength with luffa/cotton fibre pulp content.

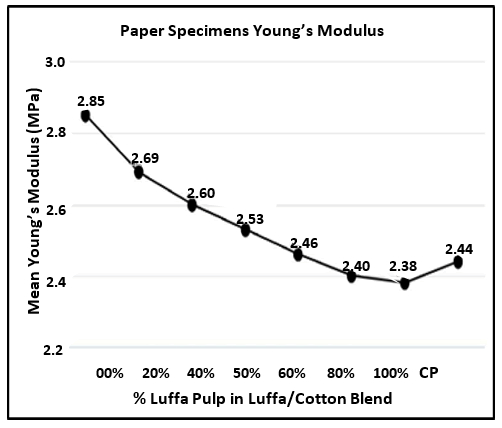

Young’s modulus

Young’s modulus of paper is the ratio of its tensile stress, that is, the force applied per unit area, to its tensile strain, that is, the extension per unit length. It is a strength property that reveals the ease with which paper can be stretched or deformed. Figure 10, shows the variation of the modulus of elasticity of the paper samples with the luffa fibre content in the luffa/cotton fibre pulp blend.

SP1 recorded the highest Young’s modulus value (2.85 MPa) while SP7, the lowest Young’s modulus value (2.38 MPa). This lowest value was slightly lower than that of the modulus of elasticity of C.P (2.44 MPa). The modulus of elasticity increased with increase in cotton fibre content in the luffa-cotton fibre pulp blend owing to the fact that cotton fibres, being longer than luffa fibres, generate an intense network of fibre crosslinks which are held together by strong hydrogen bond [18]. Also, the refining process creates greater surface area on the cotton fibre through fibrillation, such that more sites are available for hydrogen bonding, resulting in the production of paper of high strength properties. Fibrillation breaks open and exposes the cellulose fibrils so as to enhance the fibres’ surface area, resulting in improved interfibre bonding in the final paper sheet [4].

Figure 10: Variation of paper young’s modulus with luffa/cotton fibre pulp content.

The greater the proportion of luffa fibres in the luffa-cotton fibre pulp blend, the lesser the tensile strength properties of the resultant paper. Also, due to the relatively high level of refinement in the luffa fibre pulp, SP7 had a modulus of elasticity (2.38 MPa) that was comparable to that of C.P. (2.44 MPa) [9].

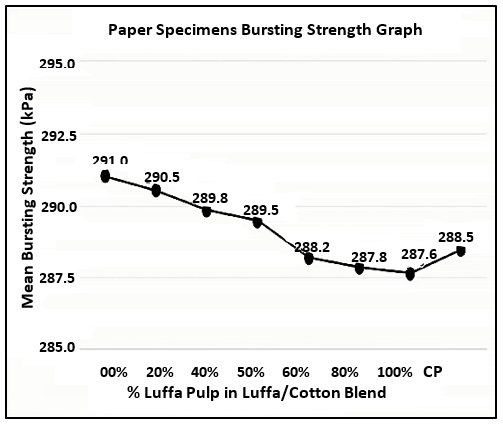

Bursting strength

Bursting strength is an indicator of how much pressure paper can tolerate before rupture. This parameter is important for papers which are expected to retain their strength longer upon exertion of pressure either accidentally or purposefully, such as packaging paper and printing paper. Excellent bursting strength enable the printing nozzle to print on the paper without causing it to buckle under pressure.

Figure 11 shows that an increase in cotton fibre content resulted in a substantial increase in the bursting strength of the paper. Paper made from equal proportions of luffa and cotton fibres (SP4) had a very high mean bursting strength of 289.46 kPa. The highest mean bursting strength value (291 kPa) was observed from SP1 while the lowest value (287.63 kPa) was observed from SP7. All paper specimens, with the exception of SP5, SP6 and SP7 recorded average bursting strength values exceeding that of C.P. This was due to the fact that cotton fibres, being inherently longer in length, impart a high level of strength through a concentrated network of entangled fibres dispersed throughout the paper matrix. Luffa fibres are shorter than cotton fibre, and as such, the greater their proportion in the paper, the lower the bursting strength value of the resultant paper. Although SP7 recorded the lowest average bursting strength value (287.63 kPa), it is reasonably higher than the theoretical threshold value of 250 kPa [15]. All the paper specimens were within the acceptable values of breaking length, with 50-100% cotton fibre content papers exceeding that of the Control Paper (C.P).

Figure 11: Variation of paper bursting strength with lufa/cotton fibre pulp content.

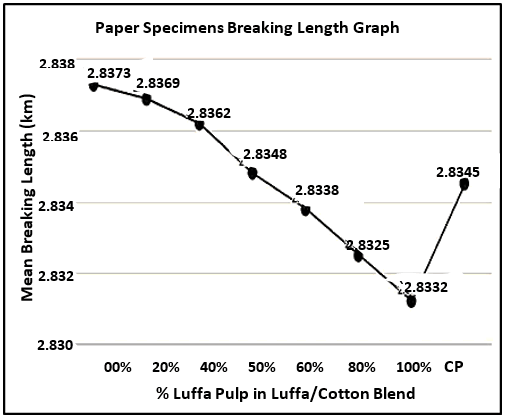

Breaking length

Breaking length is the total length of a paper strip which is such that, when it is vertically suspended on one end, would break under the impact of its own weight. This parameter is also a strength property of paper. Generally, as the proportion of long fibres increases in the pulp blend, the breaking length values of the resultant paper also tends to increase [13]. Figure 12 shows the variation of paper breaking length with increase in the proportion of luffa fibres in the paper specimens. SP1, SP2, SP3 and SP4 all recorded mean breaking lengths which were greater than that of C.P. The highest and lowest average breaking lengths were exhibited by SP1 and SP7, respectively. The highest and lowest breaking length values of 2.8373 and 2.8312 km respectively, all lie within the theoretically accepted breaking length range of 2.5-3.5 km [16].

Figure 12: Variation of paper breaking length with luffa/cotton fibre pulp content.

Breaking length generally increases as the proportion of cotton fibres in the paper specimen’s increases. This is because, cotton fibres, being considerably longer than luffa fibres, impart a high level of inherent strength on the paper through the generation of a dense network of fibre entanglements within the paper specimen matrices [5]. At 50:50 luffa-cotton pulp ratio (SP4), the mean breaking length as well as the mean bursting strength were 2.8348 km and 289.46 kPa respectively, and these were comparable to the mean breaking length and mean bursting strength values of standard Certificate Paper (C.P), which are 2.8345 km and 288.45 kPa, respectively [19,20].

Conclusion

Generally, the luffa/cotton fibre paper exhibited high levels of optical and strength properties which were comparable to, and even exceeded that of the Control Paper (CP). This means that by appropriately varying the luffa/cotton fibre proportion, paper grades of excellent quality can be manufactured using these fibres. With an excellent binder, paper made from 100% luffa fibres can qualify as specialty paper since luffa fibre possess relatively high strength to weight ratio, high cellulose content and low lignin content. Paper generated from 50:50 luffa/cotton fibre ratio, that is, SP4, was found to have physical properties comparable to and in most cases exceeding that of the Control Paper (C.P). However, more research is required to draw a clear comparison of the microscopic properties of this paper with that which already is in the market, such as morphology, and chemical bond strengths.

References

- Hammett AL, Youngs RL, Sun X, Chandra M (2001) Non-wood fiber as an alternative to wood fiber in Chinas pulp and paper industry. Holzforschung 55: 219-224.

- Abayeh OM, Garba IH, Adamu HM, Abayeh OJ (2013) Quality characteristics of Luffa aegyptiaca seed oil. Int J Sci Eng Res 4: 11-16.

- Ajuru M, Nmom F (2017) A review on the economic uses of species of Cucurbitaceae and their sustainability in Nigeria. Am J Plant Biol 2: 17-24.

- Chen Y, Su N, Zhang K, Zhu S, Zhao L, et al. (2017) In-depth analysis of the structure and properties of two varieties of natural luffa sponge fibers. Materials 10: 479.

[Crossref] [Google Scholar] [PubMed]

- Laidani Y, Hanini S, Henini G, Mortha G (2015) Study of the Luffa Cylindrica, Part II: Pulp Elaboration and Paper Characterization. Iran J Chem Chem Eng 34: 93-101.

- Oboh IO, Aluyor EO (2009) Luffa cylindrica-an emerging cash crop. Afr J Agric Res 4: 684-688.

- Ajay J (2000) High Yield Pulp of Hybrid Poplar Wood by Integrating Steam All Explosion Process as a Pre-Stage to Alkaline Pulping. University of Toronto: Master’s Thesis.

- Dutt D, Upadhyaya JS, Tyagi CH, Malik RS (2004) Studies on pulp and paper making characteristics of some Indian non-woody fibrous raw materials-Part II. NISCAIR-CSIR, India.

- Caulfield DF, Gunderson DE (1988) Paper testing and strength characteristics. In 1988 Paper Preservation Symposium: Capital Hilton, Washington, DC, October 19-21 (pp. 31-40).

- Main NM, Talib RA, Ibrahim R, Rahman RA, Mohamed AZ (2014) Suitability of coir fibers as pulp and paper. Agric Sci Procedia 2: 304-311.

- Salmela M, Alen R, Vu MTH (2008) Description of kraft cooking and oxygen–alkali delignification of bamboo by pulp and dissolving material analysis. Ind Crops Prod 28: 47-55.

- Azeez MA, Orege JI (2018) Bamboo, its chemical modification and products. Bamboo current and future prospects. 25-48.

- Market LA (2021) Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2020–2025.

- Karimah A, Ridho MR, Munawar SS, Adi DS, Damayanti R, et al. (2021) A review on natural fibers for development of eco-friendly bio-composite: characteristics, and utilizations. J Mater Res Technol 13: 2442-2458.

- Upendra K, Akshay T, Vedika H, Dhanashree K, Prathamesh S, et al. (2018) Production of paper from Groundnuts shell. Int J Adv Res Eng Technol Sci 7: 288-293.

- Zule J, Cernic M, Sustarsic M (2012) Hemp fibers for production of speciality paper and board grades. In 39th international annual symposium DITP, Bled, Slovenija.

- Long Y (2009) Biodegradable Polymer Blends and Composites from Renewable Resources. New Jersey: John Wiley & Sons.

- Forecast ZM (2018) Trend Analysis and Competition Tracking-Global Market Insights. 2018 to 2028. Fact. MR. Published.

- Al-Sulaimani (2018) Review of the history, properties and application of plant fibres.

- Environmental Management Act (2003) Management Government of Zimbabwe. pp. 45.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi