Experimental investigation and numerical analysis for waterbased ultrasonic-assisted laser drilling and trepanning with/ without magnetic assistance

Houxiao Wang

Jiangsu University, China

: J Electr Eng Electron Technol

Abstract

High quality hole drilling/trepanning with high efficiency and high precision has always been a challenging work for both scientific investigation and industrial manufacturing. Pulsed laser drilling/trepanning is a common and promising high-efficiency technology for producing high-precision cooling holes especially in aero-engine components. It has been demonstrated that pulsed solid-state lasers are particularly suitable for drilling/trepanning holes. Compared with the lasers using nanosecond, picosecond, or femtosecond pulses, the millisecond pulsed Nd:YAG laser has its overwhelming advantage of much higher drilling/trepanning efficiency, especially for industry applications. Nevertheless, a millisecond laser itself usually cannot generate high quality holes primarily owing to the serious recast layer formation with both morphological and metallurgical defects. In this talk, a promising cuttingedge water-based ultrasonic-assisted laser drilling/trepanning technology with and without magnetic assistance is reported for effectively improving the quality, efficiency and performance of millisecond-pulsed Nd:YAG laser drilling and trepanning. This novel technology is investigated experimentally and numerically. The mechanisms of this reported technology are introduced. Effects of ultrasonic-magnetic-laser parameters on laser drilling/trepanning efficiency and quality are reported by correspondingly comparing the holes drilled/trepanned with and without ultrasonic and/or magnetic assistance. The monitoring for laser drilling processes with and without ultrasonic/ magnetic assistance is demonstrated experimentally. The effects of water temperature, water-based ultrasonic vibrations and/or magnetic assistance on hole geometry, hole dimensions, recast layer formation, heat affected zone, microstructure, mechanical performance, residual stress, material removal rate, drilling/trepanning efficiency are also reported. In addition, the influence of ultrasonic assistance on transient temperature and residual stress fields for laser drilled/trepanned work pieces is also numerically analysed.

Biography

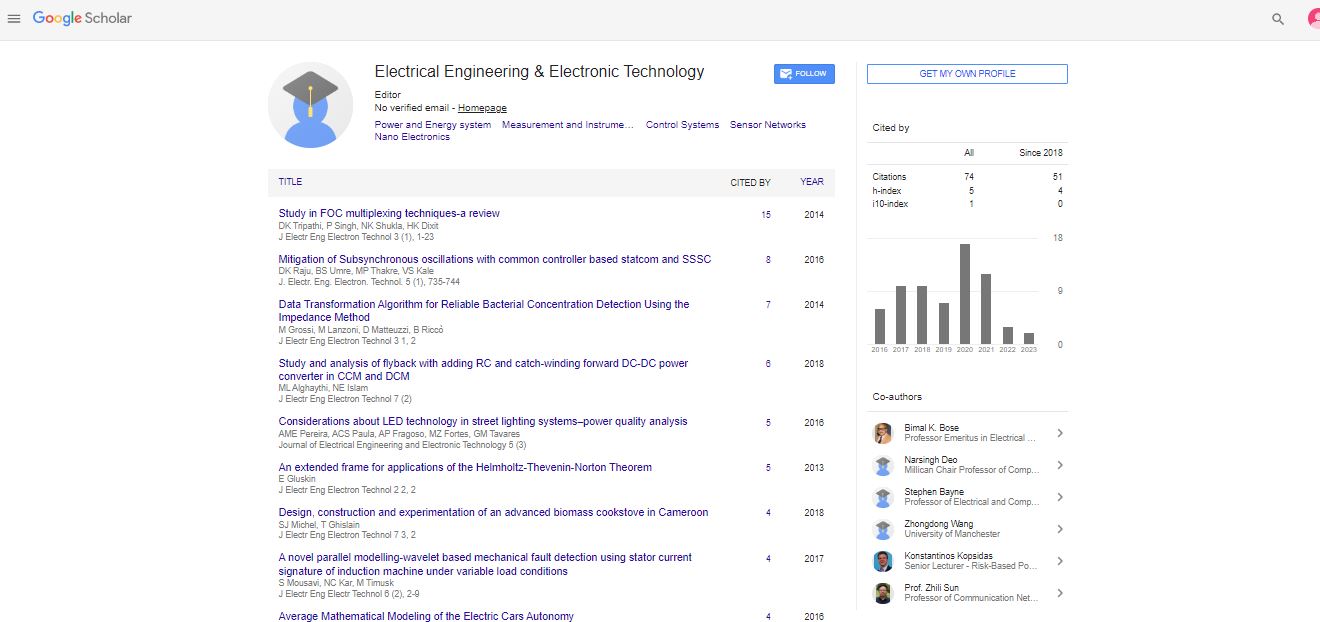

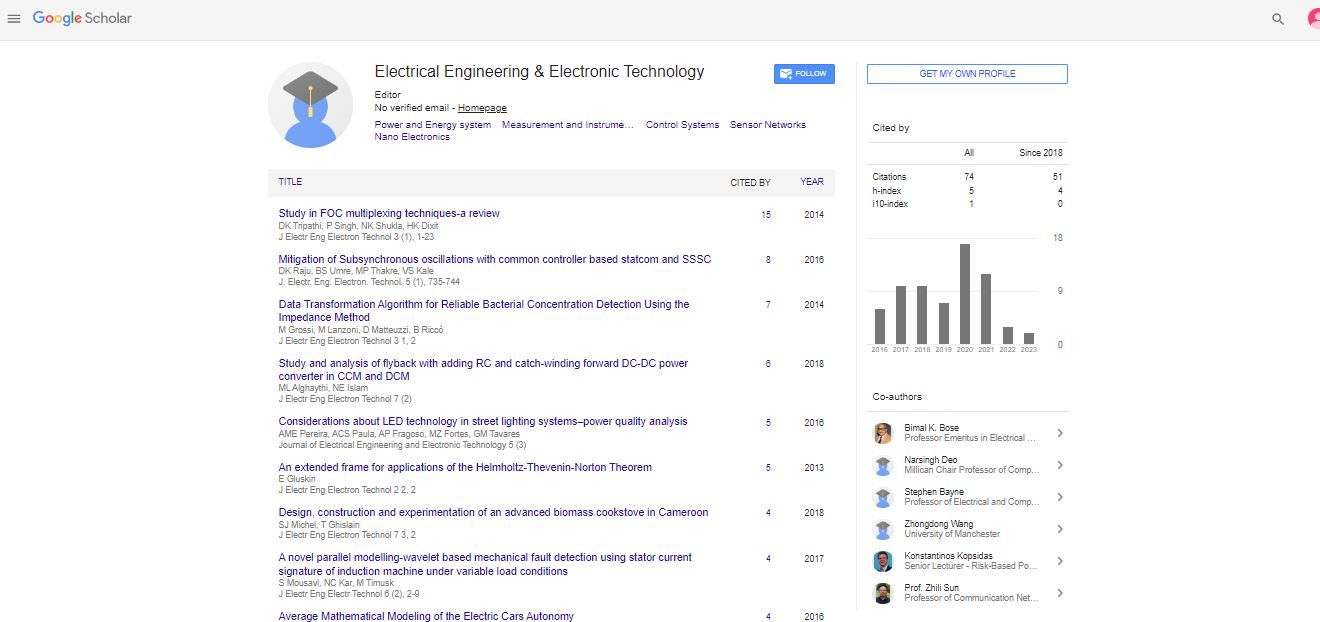

Houxiao Wang has completed his PhD in the year 2013 from Nanyang Technological University (NTU). He got the NTU Research Scholarship in 2008. He carried out collaboration with Institute of High Performance Computing in Singapore from 2009 to 2011. He is currently an Associate Professor of Jiangsu University. He has published more than 30 peer-reviewed journal papers. He is an invited Editorial Board Member of American Journal of Physics and Applications. He has been invited as or served as the (honourable) Keynote/Invited Speaker, the honourable Guest/Speaker, the (session) Chair/Co-chair, the (honourable) Organizing Committee Member and/or the Technical Program Committee Member for more than 20 important international conferences in the area. He has been invited for organizing more than 20 important international conferences held in 2019. He is currently the Member of several professional organizations such as The Optical Society of America (OSA), the Optics and Photonics Society of Singapore (OPSS), and the Materials Research Society of Singapore (MRSS).

E-mail: wanghx@ujs.edu.cn

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi