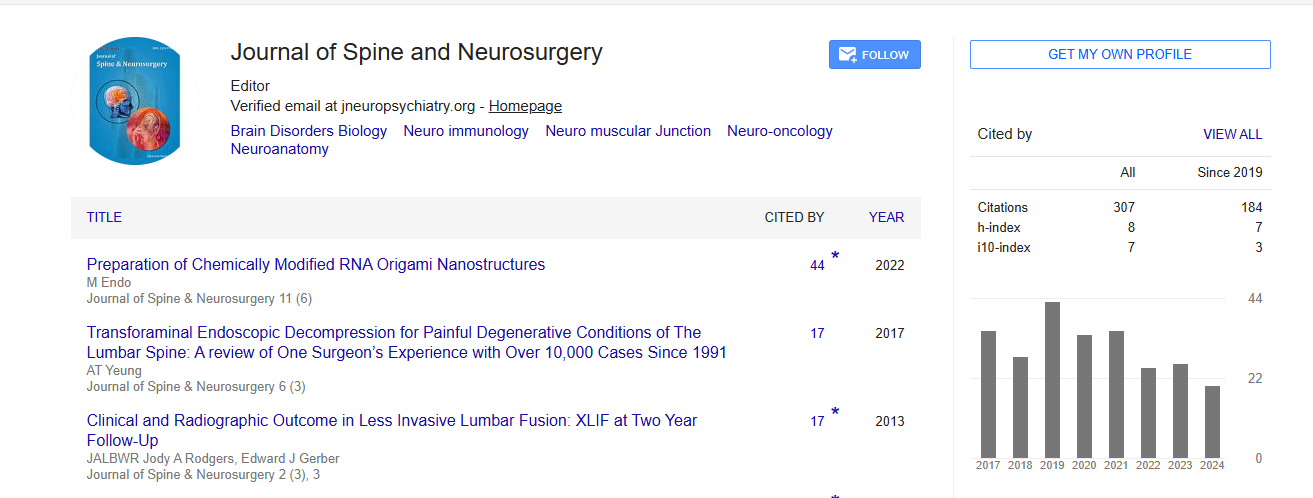

Research Article, J Spine Neurosurg S Vol: 3 Issue: 0

Long Construct Pedicle Screw Reduction and Residual Forces are Decreased Using a Computer-assisted Rod Bending System

| Antoine G Tohmeh1*, Robert E Isaacs2, Zachary A Dooley3 and Alexander WL Turner3 | |

| 1Northwest Orthopaedic Specialists, Spokane, WA, USA | |

| 2Department of Surgery, Division of Neurosurgery, Duke University Medical Center, Durham, NC, USA | |

| 3NuVasive Inc., San Diego, CA, USA | |

| Corresponding author : Antoine G Tohmeh Northwest Orthopaedic Specialists, 212 East Central Avenue, Suite 140, Spokane, WA 99208, USA, Tel: 509-465-1300 E-mail: tohmeh@comcast.net |

|

| Received: July 16, 2014 Accepted: July 30, 2014 Published: August 04, 2014 | |

| Citation: Tohmeh AG, Isaacs RE, Dooley ZA, Turner AWL (2014) Long Construct Pedicle Screw Reduction and Residual Forces are Decreased Using a Computer-assisted Rod Bending System. J Spine Neurosurg S2. doi:10.4172/2325-9701.S2-002 |

Abstract

Long Construct Pedicle Screw Reduction and Residual Forces are Decreased Using a Computer-assisted Rod Bending System

Previous biomechanical studies have shown that reduction loads placed on pedicle screws during assembly of the construct, with a rod that does not adequately fit the screw locations, can reduce the strength of the screw-bone interfaces. In this bench top study, axial pedicle screw forces on a unilateral 7-level construct were evaluated for 2 rod bending techniques: manual and computerassisted.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi