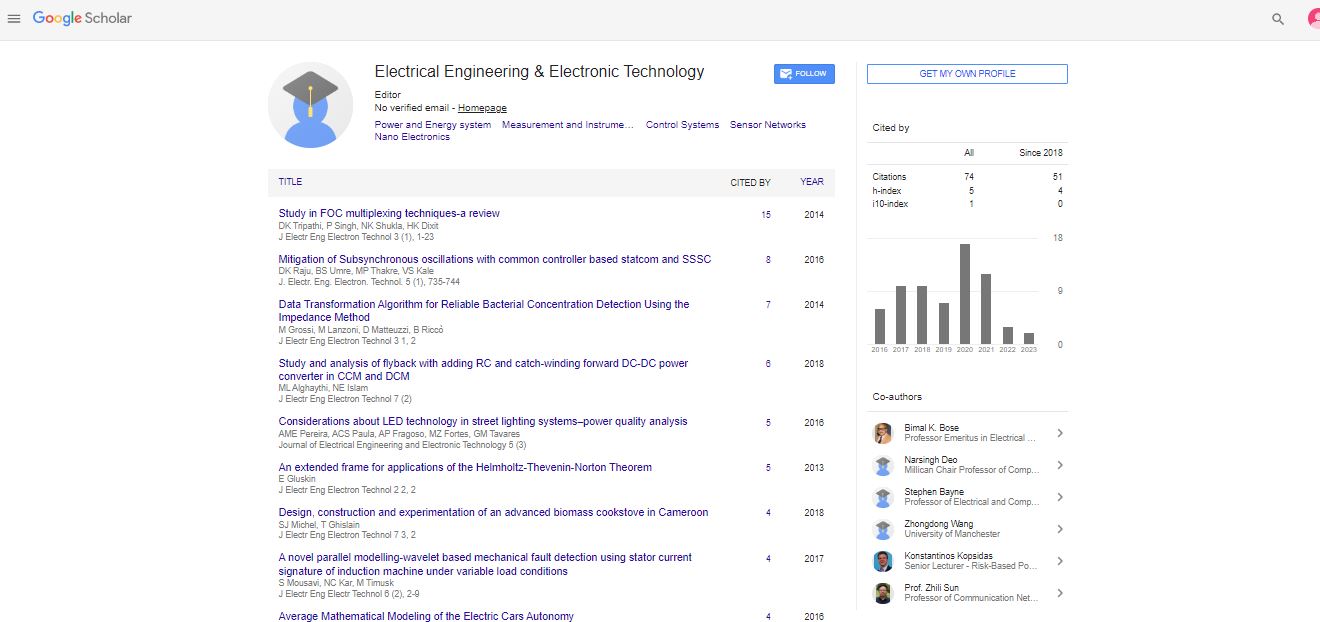

Commentary, J Electr Eng Electron Technol Vol: 11 Issue: 8

Comparative Study of Over-Current Sensing for Traction Inverters

Dale Mantey*

Department of Electrical Engineering, University of Guelph, Guelph, Canada

*Corresponding Author:Dale Mantey

Department of Electrical Engineering, University of Guelph, Guelph, Canada

Email: manteydale@gmail.com

Received date: 06 July, 2022, Manuscript No. JEEET-22-54786;

Editor assigned date: 08 July, 2022; PreQC No. JEEET-22-54786 (PQ);

Reviewed date: 15 July, 2022, QC No. JEEET-22-54786;

Revised date: 16 August, 2022, Manuscript No. JEEET-22-54786 (R);

Published date: 24 August, 2022, DOI: 10.4172/jeeet.1000923.

Keywords: Monitoring signals

Description

The over-current condition for a traction inverter can indicate flaws on control algorithms, interference on logic signals, hardware aging, or hardware misconduct. Thus, proper detection of over-current conditions during inverter operation is a critical item for inverter development and product validation. This paper reviews several widely used over-current detection methods and a few theoretically approved over-current detection methods. The main focus of this review includes the sensing bandwidth, sensing accuracy, and implementation complexity of the studied over-current detection methods. In industrial applications and automotive applications, traction inverters are commonly used to convert DC input to AC output. The operating condition of a traction inverter can affect the power conversion output characteristics, the DC input’s performance, and the inverter’s self-reliability. Current and temperature are two of the critical metrics for inverter operation reliability. Inverter components such as power semiconductor and DC link capacitors are designed to operate within a safe current range and temperature range. Out-of-range inverter operation can result in poor inverter efficiency, quick aging of the inverter components, and permanent damage on critical inverter components. Generally, critical components’ temperature and current capability are cross-coupled. Thus, the inverter over-current detection sometimes can induce the consideration of inverter operating temperature.

Traction Inverter

State-of-the-art reviews on traction inverter current sensing have categorized existing methods based on sensing locations, monitoring signals, and complexity of hardware or software implementation. Separate discussions for traction inverter open-circuit faults and short circuit faults clarify the application of traction inverter current sensing on the two major inverter operation faults. The short circuit fault can result in a sudden current increase in the traction inverter, and the study falls into the category of this review. The temperature sensing on inverter’s critical components, for instance, switching power semiconductor, can sometimes include current sensing. The temperature-current look-up tables indicate that, in some applications, accurate current sensing, especially at high current conditions, is a factor for accurate temperature sensing. Under fault-free operations, over-current detections usually require high sensing accuracy since a small percentage of current change at high current or marginal over-current operation can induce large inverter loss change. Switching power semiconductors’ tolerable short-circuit time is usually several microseconds under a short-circuit fault condition. As a result, the sensing bandwidth or response time for inverter over-current detections is critical. Another critical metric to evaluate inverter over-current detection methods is implementation complexity. In applications like electric vehicles, compact and low cost design for traction inverter is widely accepted. Thus, a detection method with simple implementation can be more competitive over those complex methods. This review discusses several widely used over-current detection methods for traction inverters. Based on the discussion on sensing bandwidth, sensing accuracy, and implementation complexity, the advantages of those widely used over current detection methods are provided. Potential commercialization requirements for those theoretical and prototyping approved methods are concluded by this review. The three-phase output over-current of a traction inverter occurs on the three-phase connections between the traction inverter and the three-phase load. It is common to sense an inverter’s three-phase output current at the location as marked in red in Figure 1. Current sensors are commonly set up at this location for phase current sensing. Under fault-free inverter operations, this can also be a location for inverter output over-current detection. The inverter high-low side short circuit is a faulty operating condition and can induce a very high current in a short period of time. To protect the switching power semiconductor from over-current failure, the response time of this over-current condition should be less than the maximum allowable short-circuit time of the switching power semiconductors. Similar to the inverter high-low side short circuit, the DC link short-circuit is another faulty operation and can induce a very high current in a short period of time. Thus, a fast response time is required for over-current detection at this location. Note that the DC link short-circuit detections are not necessarily set up inside the inverter. Setting up the DC link short-circuits detection in the DC power source a power battery, a DC power supply is an alternative. The earth ground or the housing of the traction inverter is usually configured so it has the same voltage as the DC link voltage’s midpoint or the low point. An inverter hotline-to earth ground short can also induce a very high current in a short period of time. The detection of this over-current condition is usually combination over-current detection at locations. The magnetic field based current sensing utilizes the circulating magnetic field generated by the phase current in a bus bar. A C-shape ferrite core is used to constrain the generated magnetic field, and a hall-effect field detector is used to measure the field density. With a proper design of the shape of the ferrite core, the field density in the airgap of the C-shape ferrite core can be to-scale of the bus bar current. Note that in some applications, the C-shape ferrite core can be replaced with a U-shape shield. With proper field decoupling solutions, less than 1% sensing error can be achieved without using any magnetic field constrains.

Over Current Detection

The magnetic field-based current sensing methods are commonly used for traction inverter phase current sensing. Generally, the sensing range of the phase current sensor will be set to 1.3 to 1.5 times the full load current so the redundancy can be used for over-current detection. As afore-discussed, as long as the magnetic field constrains are not saturated, the over-current detection can be as accurate as the in-range phase current sensing. The over-current response time of a hall-effect field detector output can be several microseconds. However, due to the switching noise on the inverter output phase, RC-type filters are commonly used on the outputs of the inverter phase current sensor. Thus, the response time can be further reduced. The magnetic field based current sensors do not have a galvanic connection to the phase current bus bar. As a result, no signal isolation is required and the hall effect field detector can share the same power supply with the inverter’s microcontroller. If any magnetic field constraints (such as a C-shape core or a U-shape shield) are used, the current sensor can be bulky. In a traction inverter application, a common design for a shunt resistor is a small piece of alloy with a very low resistance temperature dependency and the sensing accuracy can achieve less 1% error. Because the measurement of the voltage drop across the shunt requires a galvanic connection to the bus bar, an isolation circuitry can be required between the current sensor and the microcontroller. Similar to the magnetic field-based current sensing, if a shunt is used for traction inverter phase current sensing, the sensing range can be set up-to 1.3 to 1.5 times the full load current so the redundancy can be used for over-current detection. If an isolation circuitry is used, the shunt resistor-based over-current detection’s response time will mostly rely on the response time of the isolation circuitry. Some commercialized solutions can provide an up-to several nanoseconds response time. The over-current detection circuitry can share the same power supply with the gate drive. The benefit of having the over-current detection circuitry and the gate drive to share the same power supply is that the over-current feedback can directly regulate the gate drive without signal isolation. Regan has proposed several of shunt resistor based over-current detection solutions. Because of the usage of the filtering capacitor. The device’s on-state voltage drop will increase with the forward current. Thus, the on-state voltage drop of switching power semiconductor can be used for over-current detection. Considering that the power semiconductor’s on-state voltage-to forward current relationship is temperature-sensitive, this method may not meet the accuracy for current regulation. Usually, this method is used for high-low side short-circuit detection as afore discussed. When a high-low side short-circuit occurs, a very large on-state current will pull the device into saturation. By detecting on-state voltage drop and turn off the power semiconductor switch before the device saturates, a high-low side short-circuit faulty operation can be stopped. This type of over-current detection is also named as desaturation protection.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi