Research Article, J Electr Eng Electron Technol Vol: 11 Issue: 8

Real Time Monitoring of Impacts of Power Quality on Induction Motor Efficiency

Vinay Kant* and Narendra Kumar

Department of Electrical Engineering, Delhi Technological University, Delhi, India

*Corresponding Author: Vinay Kant

Department of Electrical Engineering,

Delhi Technological University,

Delhi,

India,

Tel: 9555806517;

Email: vinaykant_mt2k19@dtu.ac.in

Received date: 30 December, 2022, Manuscript No. JEEET-22-65879;

Editor assigned date: 02 January, 2023, PreQC No. JEEET-22-65879 (PQ);

Reviewed date: 17 January, 2023, QC No. JEEET-22-65879;

Revised date: 25 January, 2023, Manuscript No. JEEET-22-65879 (R);

Published date: 02 February, 2023, DOI: 10.4172/ 2325-9833.1000923

Citation: Kant V, Kumar N (2022) Real Time Monitoring of Impacts of Power Quality on Induction Motor Efficiency. J Electr Eng Electron Technol 12:1.

Abstract

This work focused on impacts of power quality on an online induction motor in a real time basis. The work involves creating variable conditions in the input power supply and analysing its impacts on motor performance specially efficiency. Input power supply is modulated in two aspects, first one is voltage fluctuation and second one is voltage unbalance. For the conduct of test a 10 HP induction motor is selected which is run under test condition for half an hour. During test input supply voltage is varied on both sides of the rated voltage of the motor with the help of servo voltage stabilizer. In process voltage unbalance condition was also implied on the motor by varying the voltage across three phases. All measurement parameters during test are recorded with the help of Fluke 438 II Power quality and motor analyser. The test results have indicated that motor efficiency deteriorates whenever there is a deviation from rated voltage of the motor. It also shown the same trend when voltage unbalance is increased. Thus, it implies that power quality plays a major role in the performance of the motor.

Keywords: AC Motor; Power quality; Energy conservation

Introduction

Power quality plays an important role in any industry as it can affect the performance of AC Motors which are work horses of the industry. It comprises of various aspects of input power supply system such as voltage fluctuation, voltage unbalance, distortion, flickers, Transients etc. Power quality is being getting poor due to advent of renewables sources of energy, application of nonlinear loads such as Variable frequency drives, LED Luminaries, UPS. Power quality not only causes degradation in performance but also results in premature failure of electrical equipment’s. In addition to that it also results in lower efficiency of the system, financial losses [1].

System configuration

The system consists of a 3 phase induction motor of 10 HP (7.5 kW) which is majorly used for pumping application. The motor is connected to input power supply through a servo voltage stabilizer. Fluke 438 II power quality and motor analyzer is used for recording the operational parameters related to power quality and motor. The power quality parameters which are varied in this work are voltage fluctuation and voltage unbalance. The name plate details of the system components are given in Tables 1-3.

Table 1: Motor name plate details.

Table 2: Servo voltage stabilizer detail.

Table 3: Fluke 438 II power quality and motor analyzer.

Materials and Methods

Motor under consideration is run at full load and allowed to stabilize. Fluke 438 II CT and PT probes are connected across motor starter for measurement and recording of data. The input power supply system can be controlled from servo voltage stabilizer which provides option of lowering/increasing the supply voltage and also creating unbalance between the phases. The motor is run at rated voltage and during a particular lapse of time voltage is fluctuated from its rated values; similarly voltage unbalance is created between the 3 phases of the input power supply to know about the performance of motor under these conditions. The operating parameters are recorded by the power quality and motor analyzer [2].

Measurement

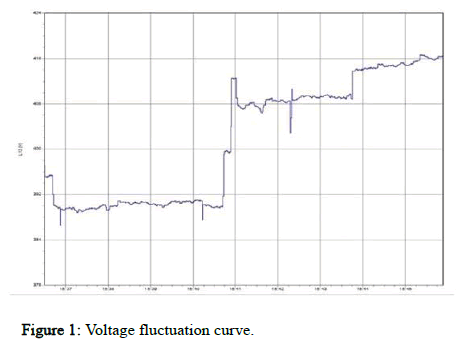

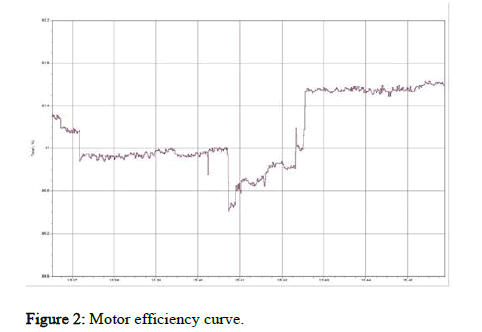

Impact of voltage fluctuation on motor efficiency: Voltage fluctuations were created in the input power supply starting from 15:30:30 hrs upto15:45:30 hrs. The data recorded by the analyzer is presented in the Table 4. Figures 1 and 2 are voltage fluctuation and Motor efficiency curve respectively for the test period.

Table 4: Voltage fluctuation vs. Motor efficiency.

Figure 1: Voltage fluctuation curve.

Figure 2: Motor efficiency curve.

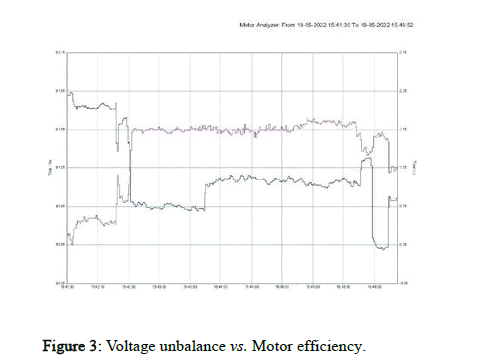

Impact of voltage unbalance on motor efficiency: Voltage unbalances were created in the input power supply starting from 15:41:30 hrs up to 15:46:30 hrs. The data recorded by the analyzer is presented in the Table 5. Figure 3 displays the voltage unbalance and its corresponding motor efficiency.

Table 5: Voltage unbalance vs. Motor efficiency.

Figure 3: Voltage unbalance vs. Motor efficiency.

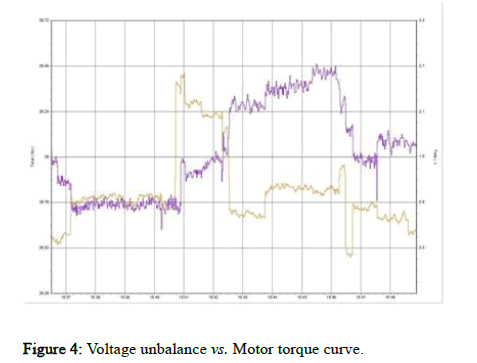

Impact of voltage unbalance on motor torque: Impact of voltage unbalance on motor torque is analyzed through the Figure 4 attached below. It is evident from the figure that both voltage unbalance and motor torque have inverse relation. In other words when unbalance increases, motor produces lesser torque [3].

Figure 4: Voltage unbalance vs. Motor torque curve.

Observation and analysis

The measurement data presented in above part presents the scope of study of behaviour of motor performance in poor power quality scenario. Since direct estimation of an online motor efficiency is difficult, by using the said motor analyzer for direct measurement of motor efficiency helped in real time estimation of motor efficiency during varying power quality scenario [4].

It was observed from the data recorded that motor efficiency tends to decrease as voltage is reduced from its rated voltage. Similarly, as the unbalance between the phases is increased, the efficiency of the motor deteriorates. These statements are corroborated from the Tables 6 and 7.

Table 6: Voltage fluctuation vs. Motor efficiency.

Table 7: Voltage unbalance vs Motor efficiency.

Conclusion

From the data and figures generated from the hardware test conducted it can be concluded that motor efficiency deteriorates whenever there is voltage deviation from the rated voltage of the motor.

Motor efficiency also tends to worsen when there is greater voltage unbalance in the input power supply.

References

- Bhuvaneswari G, Charles S, Nair MG (2008) Power quality studies on a Soft-start for an induction motor. In2008 IEEE/PES Transmission and Distribution Conference and Exposition, 21-24 April 2008, Chicago, IL, USA, pp. 1-6.

- Barros J, de Apraiz M, Diego RI (2009) On-line monitoring of electrical power quality for assessment of induction motor performance. In 2009 IEEE International Electric Machines and Drives Conference, 03-06 May 2009 Miami, FL, USA, pp: 1140-1145.

- Nadimuthu LP, Victor K, Basha CH, Mariprasath T, Dhanamjayulu C, et al. (2021) Energy conservation approach for continuous power quality improvement: A Case Study. IEEE Access, 26;9:146959-69.

- Tabora JM, Andrade VB, Lima CM, de Moura Carvalho CC, Paixão UJ, et al. (2021) Induction motors assessment: A substitution case analysis. In 2021 14th IEEE International Conference on Industry Applications (INDUSCON) 15-18 August 2021, São Paulo, Brazil, pp. 783-789.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi