Materials development using Additive Manufacturing technologies

Tomasz Kurzynowski, Edward Chlebus and Konrad Gruber

Centre for Advanced Manufacturing Technologies-Wrocław University of Science & Technology, Poland

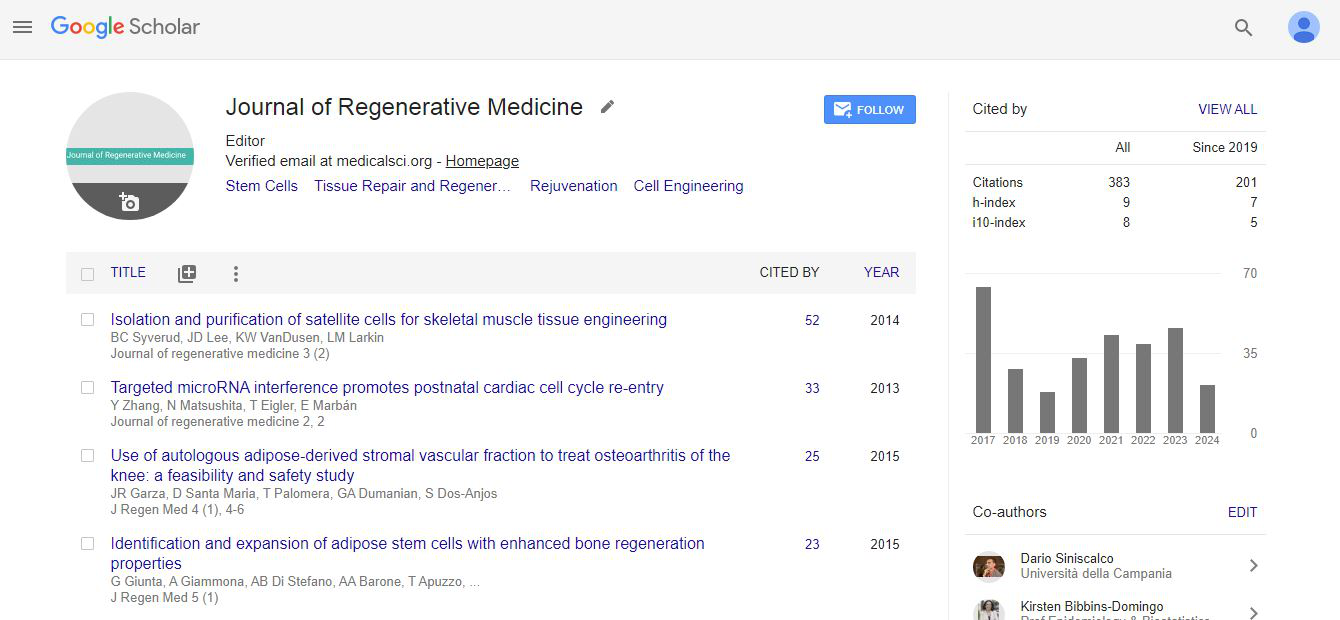

: J Regen Med

Abstract

Metal additive manufacturing creates opportunities for producing both monolithic volumes and spatial structures of complex geometries, directly from metal powders. Therefore, the technology is recognized as a promise to solve problems in many industrial sectors: automotive, aerospace and medicine. However, the problem is the availability of a wide range of materials, so that, engineers can select materials with desired properties. Many years of AM experience at CAMT-FPC resulted in proven methodology of materials development for metal additive manufacturing. The methodology allows expanding the use of metal AM in a range of industries. The following steps of materials development will be discussed: Determination of material requirements (definition of materials working conditions); selection of a group/groups of materials that match the requirements (not necessarily from the same alloy group as in conventional use); literature studies of specific materials’ properties (influence of different processing techniques on materials’ microstructures); powder material characteristics (quality control in terms of technology requirements); development of processing parameters (several-step experimental research using experiment design methods); microscopic observations, mechanical testing, special properties investigation (detailed definition of phenomena affecting material properties); post-process development (processes aimed at removing possible defects of the material or parts resulting from the nature of the AM process) and; construction and testing of the demonstrator part(s).

Biography

Tomasz Kurzynowski has completed his PhD at Wroclaw University of Science and Technology and a professional development program at Stanford University. He is the Manager of Metal Additive Manufacturing Technology & Material Laboratory, a member of the board of the Science Infrastructure Management Society. He has published more than 20 papers in reputed journals. His current research interest include additive manufacturing technologies and design methods for functional optimization or weight reduction of designed or re-engineered parts, especially for the aerospace industry.

Email: tomasz.kurzynowski@pwr.edu.pl

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi