Research Article, J Comput Eng Inf Technol Vol: 12 Issue: 6

Evaluation of Electronic Supply Chain Performance Based on Integrated Shannon's Entropy and Multimoora Approach (Case Study: National Iranian South Oil Company)

Ali Moradi Mozari*

Department of Art Science and Information Resources Management, Islamic Azad University-Ahvaz Branch, Ahvaz, Iran

*Corresponding Author: Ali Moradi Mozari, Department of Art Science and Information Resources Management, Islamic Azad University-Ahvaz Branch, Ahvaz, Iran; E-mail: ali.m.mozaari@gmail.com

Received date: 01 April, 2022, JCEIT-22-58239;

Editor assigned date: 04 April, 2022, PreQC No. JCEIT-22-58239 (PQ);

Reviewed date: 18 April, 2022, QC No. JCEIT-22-58239;

Revised date: 31 May, 2022, Manuscript No. JCEIT-22-58239 (R);

Published date: 07 June, 2022, DOI: 10.4172/2324-9307.1000235.

Citation: Mozari AM (2022) Evaluation of Electronic Supply Chain Performance Based on Integrated Shannon’s Entropy and Multimoora Approach (Case Study: National Iranian South Oil Company). J Comput Eng Inf Technol 11:7.

Abstract

The present study evaluated the electronic supply chain performance of the National Iranian South oil company based on the integrated Shannon’s Entropy and Multimoora approach in 2021. This mixed-methods survey was applied in terms of its purpose and exploratory in terms of its nature. The statistical population of this study comprised all information technology experts of the National Iranian South oil company, and 20 were selected by snowball sampling. The expert interviews continued until saturation was reached. The research tool was a researcher made questionnaire designed according to the interviews and respective theoretical literature. The DEMATEL method and N-Vivo software were used for data analysis, which led to identifying six components. According to the results, creativity and innovation with a weight of 0.364, innovation and learning with a weight of 0.353, and fast service provision with a weight of 0.340 were ranked as the first, second, and third components. However, the fourth, fifth, and sixth ranks belonged to informational and infrastructural development with a weight of 0.326, promoting information and communication technology with a weight of 0.271, and accepting the electronic supply chain management system with a weight of 0.263, respectively.

Keywords: Shannon’s entropy; Electronic supply chain; National Iranian south oil company; Multimoora

Introduction

Organizations constantly endeavor to improve their market contribution, increase profit, and achieve a competitive advantage against their competitors. To attain these goals, every organization should accentuate the efficacy and effectiveness of the supply chain. The utilization of electronic businesses (e-business) and information and communications technologies facilitates organizations’ responsiveness and adaptability to the variable needs of the market [1]. E-businesses and the internet have fundamentally transformed the structure of supply chains. The advent of new information technologies and business environments in the modern millennium has led to the emergence of the electronic supply chain [2].

A supply chain is a set of commercial processes wherein products or services are produced and delivered to customers through value-added activities implemented by involved beneficiaries. In a production supply chain, value-added activities mainly encompass product development, product design, raw material supply, product manufacturing, product packing, customer delivery, and after-sale services. The supply chain management of a manufacturing company refers to the composition of its production process in all value-added activities applied by beneficiaries granting value-added to their final products [3].

The term supply chain is a straightforward description of the associated vertical commercial processes. It is now called supply networks or supply chain networks because a company is probably involved in more than a single supply chain, and connected companies compose commercial networks. Since information technology transformed into the developer of commercial processes, supply chain management has earned amazing benefits by applying Information and Communications Technology (ICT) in different aspects of its liabilities. The information technology program first moves from data management toward automation control and then embarks on company integration. Supply chains have advanced through efficiency improvement, agility, and accuracy in the past two decades [4]. However, it was just that time when internet technology changed into a practical tool for information exchange in industry, and supply chain management initiated the alterations in the resource allocation and control methods from organizational boundaries. When the commercial practices of a company are electronically included in the value-added processes of the entire supply chain, electronic Supply Chain Management (e-SCM) turns into a new terminology. Hence, it is distinguished from conventional supply chain management through its specific characteristics, such as supporting the internet, being net-oriented, and occurring in real-time [5].

The primary challenge of supply chain management is how supply chain performances can be optimized and integrated with dispersed markets and specified demands by the newest IT advancements. To facilitate information exchange and communication in commercial networks, e-business emerged as an innovative approach to discovering value-added opportunities in supply chains by employing internet technology. The e-business approach plans and implements the back and front operations in a supply chain using web applications. The inclusion of the e-business approach in supply chain management has been proved to be a competitive method for enhancing value-added and improving process observability, agility, pace, efficiency, and customer satisfaction [6].

E-supply chain encompasses those commercial activities that include e-business approaches in supply chain processes. Electronic Supply Chain Management (e-SCM) involves employing e-business technologies to assist and optimize value-added activities in supply chains. We can find a more accurate definition of e-SCM in Norris et al.’s description: “Electronic Supply Chain Management (e-SCM) is the joint use of technology to enhance commerce processes to businesses and improve pace, power, real-time control, and customer satisfaction” [7]. Not just concerned with technological changes, e-SCM pertains to altering the culture, managerial policies, performance criteria, commercial processes, and organizational structures throughout the supply chain. E-SCM is mainly characterized by being equipped with networked e-businesses that focus on connection, cooperation, coordination, and information transparency. The networked supply chain partners share information, knowledge, and other resources in real-time. The networked communications convert the conventional information flow of the supply chain from linear transfer to end-to-end connections, i.e., information can be directly transferred from every supply chain partner to another without any data deviation and transfer delay [8].

A company should concentrate on e-supply chains in its core business competency. This concentration creates value added for both companies and the entire supply chain while preserving adaptability in unspecified markets. Internet technology can facilitate the implementation of this strategy since information exchange and commercial transactions can be realized among partners straightforwardly. The outsourcing unnecessary non-value added activities benefits from agile and adaptable structures or the development of dynamic companies [9]. It is feasible to dynamically organize a virtual company based on short or long-term partners with the help of internet technology. According to the Traditional Transaction Cost theory, making decisions about the organizational structure or procurement should balance the costs of inter-organizational relationships management and those of preserving internal operations.

In the modern competitive world, agility comprises one of the core competencies of manufacturing companies toward supplying customer needs. The costs of inter-organizational relationships management have declined with the development of internet technology. The strategy of concentrating on core competency is a logical alternative for developing an agile organizational structure and implementing mass production strategies [10].

Customer relationship management, need fulfillment, returns, procurement, supply chain relationships, planning and optimization, IF and IS integration, impact on performance, industry structure, and competitive challenge constitute the main components of e-supply chains [11].

Many studies have addressed e-supply chain performance. For example [12], displayed that e-SCM with a path coefficient of 0.34 positively impacted company performances and confirmed the mediation of e-SCM between communications and performance. Safavi and Alizadeh revealed that due to the variations in companies’ interactions with suppliers and customers and market complexities, reductions in the lifecycle of products, and the significance of making time for responding customers and enhancing flexibility in an ever-changing environment, the e-supply chain was a vital factor in the competitiveness of organizations, better performance of production units, and the development of factory sectors, leading to the emergence of innovation. The results of Barrad’s research showed that e-SCM had a positive effect on the business operations and models of the electronic manufacturing services industry. It was because they disclosed that the company’s profit increased and internal communications improved due to e-SCM implementation. Hadini found that supply chain management integrally contributed to engendering this competition, especially when information and communications technologies were implemented. Likewise, Abdirad uncovered that e-SCM directly impacted customer satisfaction.

The researcher’s concern to implement the present study is three-dimensional: First, supply chain management is the key to attaining competitive advantages and has been initially considered in the National Iranian South Oil Company, though with some deficiencies. Offering more proper services to customers, raising incomes, and reducing costs are the outcomes of applying this philosophy. The National Iranian South Oil Company can manage its performance improvement by setting goals, identifying and defining criteria, and continuously evaluating its performance. These evaluations yield appropriate perspectives about business conditions. Second, with respect to the variable world of today, the National Iranian South Oil Company requires a supply chain model connected to strategic and customer-orientation topics besides operational constraints. Third, e-SCM, which is the result of applying the internet and information systems in supply chain management, compels the National Iranian South oil company to evaluate customer value propositions and accelerates its achievement of competitive challenges.

Hence, by adopting scientific and systematic approaches, the present study aimed to answer the following questions:

What is e-SCM performance based on the integrated Shannon’s entropy and Multimoora approach (case study: National Iranian South Oil Company)?

How is e-SCM performance weighted based on the integrated Shannon’s entropy and Multimoora approach (case study: National Iranian South Oil Company)?

How is e-SCM performance ranked based on the integrated Shannon’s entropy and Multimoora approach (case study: National Iranian South Oil Company)?

Materials and Methods

The present field survey was a mixed and exploratory study in reference to its examined population and applied in terms of its purpose. The research environment was characterized by minimum intervention since the researcher endeavored to carry out a cross-sectional evaluation of the conditions governing the study variables with regard to participants’ perspectives by selecting a certain statistical population and sample. The statistical population of the research included the chief and middle managers of the National Iranian South oil company.

The research pivoted around the perspectives of experts whose knowledge, specialization, and high accuracy about e-SCM were extensively imperative. Therefore, the statistical population of the research encompassed 20 information technology and supply chain experts of the National Iranian South Oil Company, with over seven years of work experience in supply chain and master’s degree in the ICT management (computer), energy optimization, and productivity and structure engineering administrations. The study instrument was a researcher-made questionnaire developed from expert interviews and theoretical literature. The face and content validity of the questionnaire was checked by five specialists and experts (the supervisor and some pundits) in the first and second phases. After the collection of the questionnaires, the data were entered into the SPSS software, and the reliability index, whose value should be ≥ 0.7, was estimated by the Cronbach alpha method in the first phase. The present study calculated the first-phase Cronbach alpha coefficient of the questionnaire at 0.872, indicating the reliability of the questionnaire with respect to what was mentioned earlier concerning the reliability of the instrument. The second-phase reliability was also examined by the incompatibility rate. In the present study, the incompatibility rate was calculated for all pairwise decision matrices and equaled <0.1, denoting the correctness of the comparisons. The DEMATEL and NVivo software were used for data analysis. NVivo is a software package for qualitative data analysis and is designed and released by an international institution developing qualitative research software. Shannon’s entropy indicates the uncertainty rate in a continuous probability distribution. The core idea of this method is that the more the values of an index are dispersed, the more important it is. The Multimoora multi-objective optimization method, which benefits from ratio analysis, was introduced by Brauers and Zavadskas. This method was completed by the use of a full multiplicative form.

Results

The descriptive statistics results pertaining to the demographic variables revealed that males constituted a large number of the 20 participant statistical sample. In this group, 100% of the sample was investigated. Seven respondents (35%) were 30-40 years old, eight (40%) were 41-50 years old, and two (25%) were above 50. five participants had bachelor’s degrees, 12 (60%) had master’s degrees, and 3 (15%) had Ph.D. degrees. According to Table and Graph 4-4, six participants (15.3%) had work experiences of 10-15 years, nine (23.1%) had work experiences of 16-20 years, and 5 (61.6%) had experiences of >20 years.

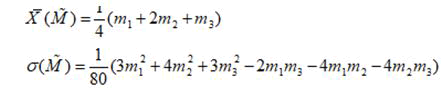

Lee and Li propose employing the developed mean and standard deviation based on the probability of fuzzy events for ranking fuzzy numbers [13]. According to their study, if is a fuzzy number, and its average and dispersion are estimated by the relations below:

The relations above helped with ranking decision units (supply chains) in Table. The superiority of an e-supply chain over the other in Table 1 indicates the privilege of a component over the other. For example, the superiority of the innovation component over ICT promotion denotes that innovation has contributed to ICT promotion in the electronic performance evaluation.

| Component | Rank | Weight |

|---|---|---|

| Creativity | 1 | 0.364 |

| Innovation | 2 | 0.353 |

| Fast service provision | 3 | 0.34 |

| Informational and infrastructural development (software and hardware) | 4 | 0.326 |

| Promoting information and communication technology | 5 | 0.271 |

| Accepting the electronic supply chain management system | 6 | 0.263 |

Table 1: Ranking supply chains by the fuzzy data envelope analysis model.

Discussion

The first research question interrogated what the e-supply chain performance was according to the integrated Shannon’s entropy and Multimoora approach in the National Iranian South Oil Company. Table 2 represents the system of evaluation indices considered for this problem. As shown in Table 3, these indices encompass fast service provision, creativity, promoting information and communication technology, informational and infrastructural development (software and hardware), innovation, and accepting the electronic supply chain management system. In real-world problems, it is impossible to measure all indices with accuracy and certainty. Here, cost is a fuzzy index while other indices are certain. It is worth mentioning that the e-supply chain was evaluated at the company level, and every index was measured in relation to fast service provision, creativity, promoting information and communication technology, informational and infrastructural development (software and hardware), innovation, and accepting the electronic supply chain management system. The findings of this hypothesis are in line with the results of the studies by Zardosht and Estakhrian, Darvishian, Rabi and Karghar, Amirian and Estakhrian, Bensbih, Abdira and Pudjiastuti in the fast service provision factor. Likewise, our results conform to the research findings discovered by Safavi and Alizadeh, Shokati and Shafia, Jing, Zhang and Moala regarding innovative and commercial performance. The results also correspond with the findings of studies conducted by Darvishian, Rabi, and Kargar, Shokati and Shafia, Saberi, Faraji and Daemi, Jabaleh, Bensbih, Hadini, Moala, Barrad and Zhang in the promoting information and communications technology factor. Lastly, the results coincide with the findings of the survey conducted by Sheikh Mamo and Bavarsad in the accepting e-SCM system factor. However, no study aligned with the (software and hardware) informational and infrastructural development and innovation factors was found.

| Row | Index | Rank |

|---|---|---|

| 1 | Increasing customer service quality | 0.288 |

| 2 | Promoting customer satisfaction | 0.443 |

| 3 | Promoting service quality | 0.397 |

| 4 | Preserving customers and building loyalty | 0.393 |

| 5 | Online services | 0.402 |

| 6 | Improving efficiency | 0.356 |

| 7 | Online services | 0.254 |

| 8 | A vital factor for organizational competitiveness | 0.409 |

| 9 | Increasing adaptability | 0.245 |

| 10 | Accentuating customer response time | 0.213 |

| 11 | Reducing lifecycle of products | 0.209 |

| 12 | Market complexity | 0.384 |

| 13 | Interaction manner of companies with suppliers and customers | 0.369 |

| 14 | Delivery time | 0.232 |

| 15 | Delivery performance | 0.09 |

| 16 | The efficiency of sales invoice delivery methods | 0.111 |

| 17 | Delivery reliability | 0.129 |

| 18 | Training | 0.313 |

| 19 | Honesty and trust | 0.219 |

| 20 | Making empowered and competitive | 0.102 |

| 21 | Electronic procurements | 0.089 |

| 22 | Supervising current systems | 0.202 |

| 23 | Technical problems of process automation | 0.19 |

| 24 | Information correctness | 0.091 |

| 25 | Improving and developing commercial relationships of the organization | 0.349 |

| 26 | Information system security | 0.367 |

| 27 | Information quality and accuracy | 0.138 |

| 28 | Internet ICTs | 0.389 |

| 29 | Websites | 0.276 |

| 30 | The strategy of supporting supplier capacities | 0.302 |

| 31 | e-supply chain adaptability | 0.187 |

| 32 | Organizational scale | 0.111 |

| 33 | The creativity of supreme executive managers | 0.297 |

| 34 | Risk appetite | 0.109 |

| 35 | Predicting future demands | 0.156 |

| 36 | Coordinating and integrating supply chains | 0.12 |

| 37 | Data integration | 0.076 |

Table 2: Ranking fuzzy data sub-criteria.

| Row | Index | Rank |

|---|---|---|

| 1 | Increasing customer service quality | 0.287 |

| 2 | Promoting customer satisfaction | 0.415 |

| 3 | Promoting service quality | 0.397 |

| 4 | Preserving customers and building loyalty | 0.39 |

| 5 | Online services | 0.375 |

| 6 | Improving efficiency | 409 |

| 7 | Online services | 0.311 |

| 8 | A vital factor for organizational competitiveness | 0.319 |

| 9 | Increasing adaptability | 0.34 |

| 10 | Accentuating customer response time | 0.39 |

| 11 | Reducing lifecycle of products | 0.234 |

| 12 | Market complexity | 0.384 |

| 13 | Interaction manner of companies with suppliers and customers | 0.369 |

| 14 | Delivery time | 0.26 |

| 15 | Delivery performance | 0.109 |

| 16 | The efficiency of sales invoice delivery methods | 0.111 |

| 17 | Delivery reliability | 0.129 |

| 18 | Training | 0.313 |

| 19 | Honesty and trust | 0.286 |

| 20 | Making empowered and competitive | 0.167 |

| 21 | Electronic procurements | 0.108 |

| 22 | Supervising current systems | 0.212 |

| 23 | Technical problems of process automation | 0.198 |

| 24 | Information correctness | 0.114 |

| 25 | Improving and developing commercial relationships of the organization | 0.276 |

| 26 | Information system security | 0.254 |

| 27 | Information quality and accuracy | 0.156 |

| 28 | Internet ICTs | 0.389 |

| 29 | Websites | 0.276 |

| 30 | The strategy of supporting supplier capacities | 0.302 |

| 31 | e-supply chain adaptability | 0.187 |

| 32 | Organizational scale | 0.111 |

| 33 | The creativity of supreme executive managers | 0.297 |

| 34 | Risk appetite | 0.109 |

| 35 | Predicting future demands | 0.187 |

| 36 | Coordinating and integrating supply chains | 0.216 |

| 37 | data integration | 0.065 |

Table 3: Weighting sub-criteria of Shannon’s entropy data.

The second question pertained to the e-supply chain performance of the National Iranian South oil company based on the integrated Shannon’s entropy and Multimoora approach. We can argue that modern organizations need to benefit from fit models, such as e-SCM, toward realizing competitive advantages and customer expectations to earn privileged positions and preserve them. The customers of modern organizations cooperate with organizational members in goods production, service provision, procedures and processes, knowledge development, and competitive power. Wu and Chang presented a conceptual model for perceiving the acceptance and release of e-SCM in various stages among commercial partners and claimed that technology structures, partnership structures, industry type, and organization size were effective factors in this area. Al-Zubi studied e-SCM by applying software and computer systems.

Diverse advances in IT capacities have rapidly revolutionized the industry compared to the past decade. IT adoption and implementation exert distinctive competitive characteristics to companies and supply chains. IT acceptance and its efficient implementation can improve cooperation among supply chain members through promptly transferring and distributing accurate information and applying information systems, leading to the enhanced efficiency of supply chains [14].

The second research question addressed how e-SCM was weighted based on the integrated Shannon’s entropy and Multimoora approach in the National Iranian South Oil Company. Table 3 shows the results of testing the respective hypothesis of this question concerning the weighting of decision units (supply chains). The superiority of an e-supply chain over the other indicates that a supply chain is more advantageous than the other. For example, the superiority of the innovation component over ICT promotion implicates that this component has contributed to ICT promotion in evaluating electronic performance. Every component was weighted in the following order: creativity (0.364), innovation (0.353), fast service provision (0.340), informational and infrastructural development (0.271), and accepting e-SCM system (0.263).

The findings of testing this hypothesis are in line with the results of studies conducted by Zardosht and Estakhrian, Darvishian, Rabi, and Kargar, Amirian and Estakhrian, Bensbih, Abdirad and Pudjiastuti in the fast service provision factor. The results also correspond with the findings of the research carried out by Safavi and Alizadeh, Shokati and Shafia, Jing, Zhang, and Moala in the commercial and innovative performance factor. In their surveys, Darvishain, Rabi, and Kargar, Shokati and Shafia, Saberi, Faraji and Daemi, Jabaleh, Bensbih, Hadini, Moala, Barrad, and Zhang yielded results similar to our findings regarding the ICT promotion factor. Meanwhile, the same results were obtained by the current study and Sheikh Mamo and Bavarsad’s survey in the accepting e-SCM system factor [15-19]. However, no study aligned with the (software and hardware) informational and infrastructural development and innovation factors was found. We can explain the question above by arguing that organizations now require new thoughts and novel conceptions for their growth and survival. Product or service innovation is generally a difficult and risky task; whose success calls for employing secure methods. Likewise, preserving relationships with other partners and customers, benefitting from prompt and accurate information, maximizing chain performance, and making supply chain management agile are possible by applying an information system in an internet platform. As the results of Safavi and Alizadeh’s study show, due to the variations in companies’ interactions with suppliers and customers and market complexities, reductions in the lifecycle of products, and the significance of making time for responding customers and enhancing flexibility in an ever-changing environment, the e-supply chain was a vital factor in the competitiveness of organizations, better performance of production units, and the development of factory sectors, lead to the emergence of innovation. Thus, the supply chain recognition and its implementation assist with organizational excellence and the better commercial performance of the manufacturing unit. Furthermore, Zhang’s research showed that information technology could enhance supply chain management performance by rendering real-time information to the coordination process of different supply chain players. Therefore, e-SCM is defined as employing information and communications technology to improve supply chain management operations.

The third question of the research interrogated how the e-supply chain performance was ranked in the National Iranian South Oil Company according to the integrated Shannon’s entropy and Multimoora approach.

Tables 3 and 4 represent the results of testing the respective hypothesis, i.e., the ranking of the decision units (supply chains). The priority of an electronic supply chain over the other in Table 2 implicates that a supply chain network is advantageous over the other. For example, the superiority of the innovation component over ICT promotion indicates that the innovation component contributes to ICT promotion in electronic performance evaluation. In this respect, creativity, innovation, fast service provision, informational and infrastructural development (software and hardware), information and communications technology promotion, and accepting e-SCM system were ranked as the first, second, third, fourth, fifth, and sixth components, respectively [20].

| Rank | Main components of e-supply chain performance evaluation |

|---|---|

| 1 | Creativity |

| 2 | Innovation |

| 3 | Fast service provision |

| 4 | Informational and infrastructural development (software and hardware) |

| 5 | Promoting information and communication technology |

| 6 | Accepting the electronic supply chain management system |

Table 4: Ranking main components of e-supply chain performance evaluation.

The results of testing this hypothesis are partly in line with the findings of studies conducted by Zardosht and Estakhrian, Darvishian, Rabi, and Kargar, Amirian and Estakhrian, Bensbi, Abdirad and Pudjiastuti in the fast service provision factor. The results also correspond to the research findings of Safavi and Alizadeh, Shokati and Shafia, Jiang, Zhang, and Moala concerning innovative and commercial performance. Similar results were presented by Darvhshian, Rabi and Kargar, Shokati and Shafia, Saberi, Faraji and Daeimi, Jabaleh, Bensibih, Hadini, Moala, Barrad and Zhang regarding the ICT promotion factor. Congruent results were also obtained by Sheikh Mamo and Bavarsad in the accepting e-SCM system factor. However, no study aligned with the (software and hardware) informational and infrastructural development and innovation factors was found. We can explain the question above by asserting that the expansion of information technology to different social structures in the modern world has made the fast service provision of producers a fundamental and crucial factor in customer preservation and customer relationships management. In the meantime, supply chain management has not been left behind by benefiting from electronic tools and electronic businesses, especially the internet. Supply chain management encompasses a chain of key processes embracing divergent businesses, ranging from main suppliers to the end consumers. Supply chains involve the products, services, and information that yield value-added to both customers and stakeholders. Revealing coinciding results, Bensbih found that supply chain management basically contributed to competition creation, especially when information and communications technologies were employed [21,22].

Conclusion

Concerning the results of the study and the evaluation of the e-supply chain performance based on the integrated Shannon’s entropy and Multimoora approach, it is suggested that the information about the inventory in different supply chain sectors, product demands, transportation time, etc. be accessed by all chain members. This information should be managed and controlled by the application of strict and regular policies. Moreover, the National Iranian South oil company’s e-supply chain integration and coordination, stemming from a robust and solid composition of processes among suppliers, commercial partners, support units, and distribution channels, are suggested.

References

- Toghroli M, Mohammadi M (2019) Supply chain management. 2nd International Conference on Management, Accounting, Banking, and Economy in Iran 2005 Horizon, Mashhad.

- Safavi S, Alizadeh A, Fahimi S (2018) Investigating the effect of electronic supply chain management (e-SCM) on commercial and innovative performances of the employees of manufacturing units or factories. 3rd National Conference on Iranian Economy, Management, Accounting, Jiroft.

- Klinčar A, Zoroja J (2021) Supply Chain Management Supported by E-Invoicing: Cluster Analysis Approach to E-Invoicing. Int J E-Services Mobile App 13:43-59.

- Sanjaya, AAP, Putra IGJE, Estiyanti NM (2021) Sistem Informasi E-Supply Chain Management Budidaya Jamur Tiram Pada Oka Jamur Bali. Jutisi: Jurnal Ilmiah Teknik Informatika dan Sistem Informasi 9:129-140.

- Gupta V, Jayant A (2021) Low-Carbon Supply Chain Management: A Fuzzy-DEMATEL Analysis of Some Practical Issues of Indian Manufacturing Industries. In: Muzammil, M, Chandra A, Kankar PK, Kumar H (eds)Recent Adv Mech Eng Springer, Singapore:pp 33-42.

- Hadini M, Bensbih S, Trifess M, Bouksour O, Rifai S (2020) Business Models: A Strategic Link to E-Supply Chain Management. Int J Mech Eng Tech 11:1-5.

- Abdirad M, Krishnan K. Customer Satisfaction Assessment of E-Supply Chain Quality in Online Shopping: A Case Study. Preprints 1-21.

- Zhang X, Tavitiyaman P (2020) e-Supply Chain Management in Tourism Destinations. In: Xiang Z, Fuchs M, Gretzel U, Höpken W, (eds). Handbook of e-Tourism. Springer, Cham. Switzerland AG:pp 1-21.

- Barrad S, Valverde R (2020) The Impact of e-Supply Chain Management Systems on Procurement Operations and Cost Reduction in the Electronics Manufacturing Services Industry. J Media Manag Entrep 2:1-27.

- Pudjiastuti L, Indrawati HA, Arrum DA, Pudjiastuti L (2020) Integrated E-Supply Chain Management Systems Services as a form of Acceleration of Development in Indonesia. Int J Sup Chain Mgt 9:426.

- Jabaleh M, Ranjkesh S, Aliari Sh, Ghiasi MR (2016) Identifying and implementing critical factors affecting e-supply chain management (Case study: Small and medium enterprises). 1st International Conference on Information Technology,USA.

- Asadi M, Alipour H (2017) Investigating the mediating role of electronic supply chain management in the impact of communication and trust on the performance of small and medium industries in Ardabil province. 4th national Conference on the economy, Islamic-Iranian Culture and Management, Ardabil.

- Nojavan, Majid, Ghazanfari, Mehdi (2004) Ranking of Fuzzy Numbers Using Utility Index, 3rd National Conference on Industrial Engineering, Tehran.

- Darvishain M, Rabi AR, Kargar MH (2017) The effect of the Internet of Objects on electronic supply chain management (Case study: Golestan Food Holding). 3rd Annual Conference on Business economy and Management, Tehran.

- Amirian Z, Estakhrian AR (2020) The effects of electronic supply chain management on the electronic retail industry: Investigating the performance of E-SCM dissemination from a multistage perspective. International Conference on New Research in Electrical Engineering, Computer, Mechanics and Mechatronic in Iran and the Islamic World, Karaj.

- Bensbih S, Hadini M, Trifess M, Bouksour O, Rifai S (2020) Business Models: A Strategic Link to E-Supply Chain Management. Int J Mech Eng Technol 11:1-5.

- Faraji J, Daemi V, Faraji Sh (2017) The effect of electronic business on the supply chain management of goods (Case study: Tehran University of Medical Sciences). 3rd Annual Conference on Business Economy and Management, Tehran.

- Norris G, Hurley JR, Hartley KM, Dunleavy JR, Balls JD, E-Business and ERP: Transforming the Enterprise, John Wiley and Sons Inc, 2000.

- Saberi A (2017) The characteristics and structure of a purposeful electronic supply chain. National Conference on Applying Modern technologies in Sciences, Engineering, Electricity, Computer and IT, Tehran.

- Sheikh Mamo MR, Bavarsad B (2014) Recognizing the effective factors in accepting the electronic supply chain management system: Using a technological, organizational, and environmental framework (Case study: South Oil Companies). International Conference on Accounting and Management, Tehran.

- Shokati Kh, Shafia MA (2017) Considering the return of goods in the electronic supply chain in inventory rooting location issue. 1st International Conference on Systems Optimization and Business Management, Babol.

- Zardosht Z, Estakhrian Haghighi AR (2020) The difference between SCM and E-SCM and the effect of information technology on them. International Conference on New Research in Electrical Engineering, Computer, Mechanics, and Mechatronic in Iran and the Islamic World, Karaj.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi