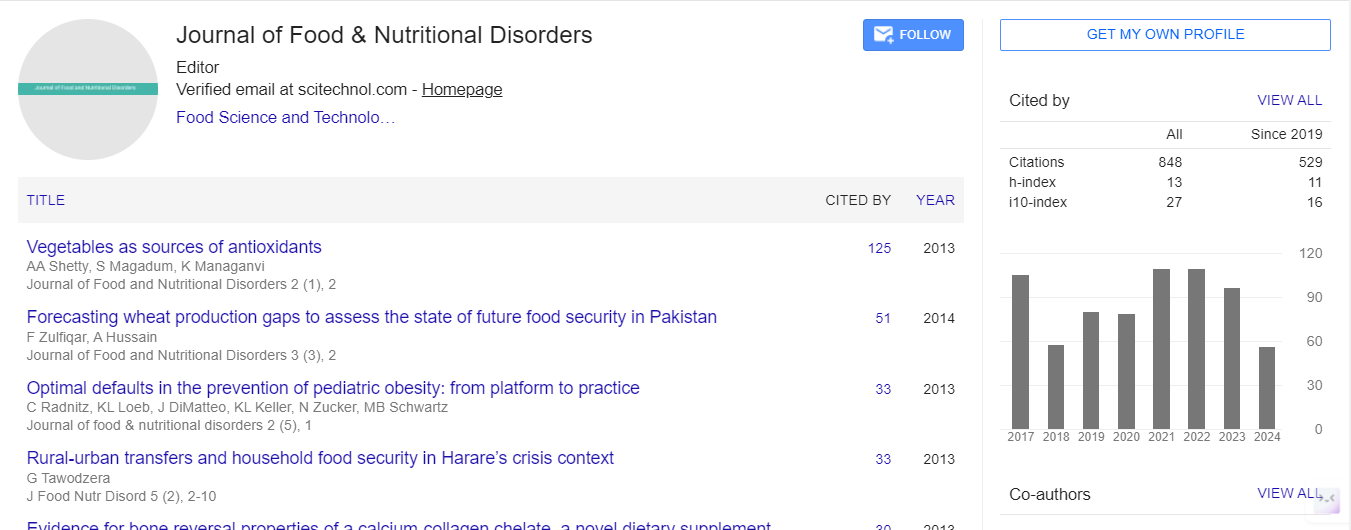

Optimization of temperature and time as the main factors to reduce acrylamide formation in four bread recipes

Isaac W Ofosu, Herman E Lutterodt, Gloria M Ankar-Brewoo and Rosemond Akuokoh

Kwame Nkrumah University of Science and Technology, Ghana

: J Food Nutr Disor

Abstract

Acrylamide is a probable carcinogen common in heat processed foods renders such foods as bread worrisome to consume. The recent study suggests that acrylamide should be profiled in specific foods for regulatory purposes and it can be continued to stress manufacturers who must meet consumers’ preference of zero additives in order to control acrylamide content of foods. Thus, the purpose of this study was to determine how the two main factors of bread baking, interact to produce acrylamide among different recipes for bread production. Baking conditions of temperature (150-190 °C) and time (15-45 min) were designed in two-Factor Interaction (2FI), Response Surface D-optimal process to produce 38 pieces of bread. Purified extracts of bread samples were obtained using QuEChERS method and the concentration of acrylamide determined using HPLC. Data was processed by fitting a 2FI process order followed by diagnostics to remove outliers, and subsequently low acrylamide production was optimized for individual bread recipes. The sampled bread was projected to produce 1.79×10-2 mg/g for “Sugar bread” relative to 2.06×10- 2 mg/g for “Brown Bread” at baking conditions of a minimum baking temperature and time of 150 °C and 15 min, for all the bread samples, apart from “Tea Bread”, which required a high temperature (190°C), short time (15 min). Subsequently, the validated baking condition presented 1.45×10-2 mg/g acrylamide for “Sugar Bread” and 1.62×10-2 mg/g for “Brown Bread”. Again, for “Butter Bread” which was projected to require a baking temperature of 150oC, and 45 min for baking to meet consumer preference, a validated acrylamide content of 1.56×10-2 mg/g was obtained. Since from literature the acrylamide content of bread is characteristically higher and posing high risk, the level of risks could considerably reduce when lower temperature and shorter time is used, though some bread sensory characteristics could be traded off.

Biography

Isaac W Ofosu obtained his doctoral degree in Food Science and Technology from Kwame Nkrumah University of Science and Technology, here in Kumasi, Ghana. He is a Senior Lecturer and facilitates learning and research in Food Systems Chemistry, Toxicology and Risk. He has published over 20 papers in reputed journals. He serves as a reviewer and editorial board member of some international journals.

E-mail: ofosuiw.sci@knust.edu.gh

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi