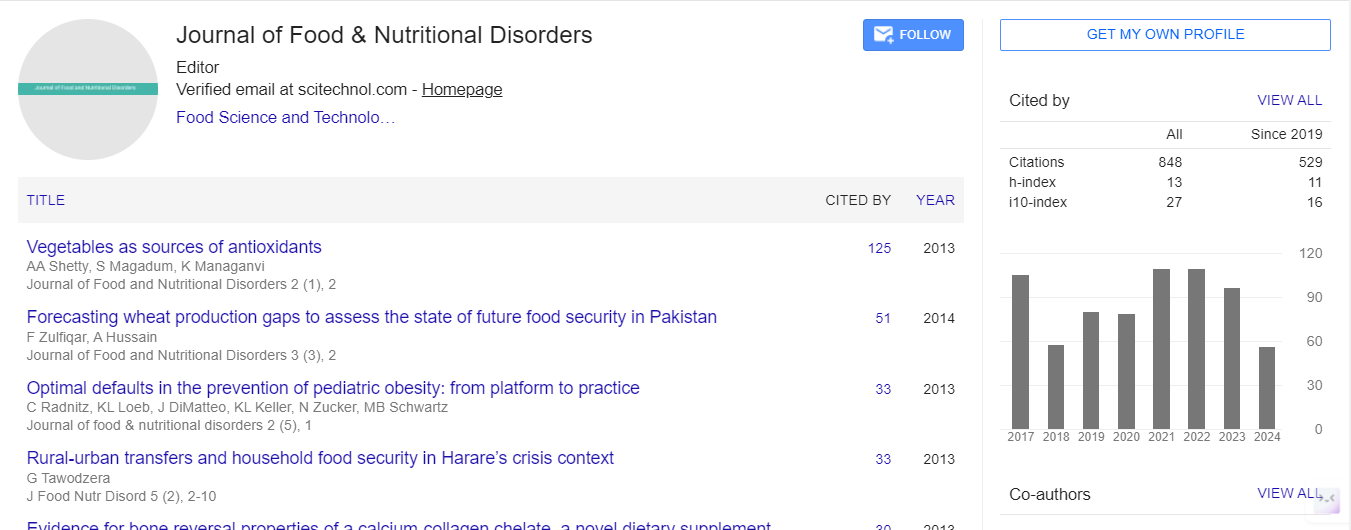

The qualification of crispy pineapple sheets; presented as a new style of pineapple snack

Rungtiwa Kongngoen and Jirapa Pongjanta

Rajamangala University of Technology Lanna, Thailand

: J Food Nutr Disor

Abstract

Normally, many pineapple products in Thailand are processed and presented as jam, paste and candies. Most of them are deteriorated and have no longer in shelf life due to their high levels of moisture content and water activity. To preserve the product safely, the product must have the low values of moisture content and water activity. Drying is one of the method to solve the problem and be used to produce this product. To develop the utilization of pineapple, which is a popular fruit planting in the Northern part of Thailand such as Lampang, is used as the main raw material combination with potato for producing a new style of pineapple snack presented as crispy pineapple sheets. The optimal ratio between pineapple and potato is 80:20 and processed by using tray dryer with drying temperature at 75OC for 6 hrs. affected the highest liking scores of product in appearance color odor taste textural character and overall preference in the range of 7.67-8.10 scores. The physical properties in color were 62.99±0.10 10.03±0.45 43.67±0.49 , respectively and the fracturability value was 3.68±0.61 N. The chemical properties in water activity was 0.33±0.01 and also the percentage of moisture content ash protein and fiber were 6.47±0.04 3.29±0.21 3.21±0.62 and 3.24±0.16, respectively. The microorganism analysis was found that the crispy pineapple sheets had the levels of microorganism limited in standard regulation (Thai Industrial Standards number of 1534-2541). The calculated for nutritional value of this product was 128 Kcal/100 g of food energy. The study of 200 consumers acceptance on pineapple snack, it was found that all of consumers accepted and liked the product in the 9-point hedonic scale of like moderately to like very much. To identify shelf life index and test for product shelf life using Q10 technique. The temperature is the one factor resulted to accelerate the reaction in food affected the change of sensory quality. With the Q10 of 2.14, the predicted shelf life of product at 30 OC was 65 days and at 4 OC was 479 days in aluminum foil packaging.

Biography

Rungtiwa Kongngoen had completed her M.Sc on Food Science from Kasetsart University, Thailand in 1998. She is an Assistant Professor within the field of Food Science and Technology in the faculty of Science and Agricultural Technology, Rajamangala University of Technology Lanna Lampang Campus. Her research interests include confectionery technology, dairy technology, and food microbiology and food product development. She had 2 articles published in Thai journals.

E-mail: tukkatafay@gmail.com

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi