Research Article, J Fashion Technol Textile Eng S Vol: 0 Issue: 3

3D Product Development for Loose-Fitting Garments Based on Parametric Human Models

Sybille Krzywinski* and Jana Siegmund

Dresden University of Technology, Institute of textile machinery and Textile High Performance Material Technology, High Strabe 601069 Dresden, Germany

*Corresponding Author : Sybille Krzywinski

Dresden University of Technology, Institute of Textile Machinery and High Performance Material Technology, 601062 Dresden, Germany

Tel: +49 351 46339312

Fax +49 351 46339301

E-mail: sybille.krzywinski@tu-dresden.de

Received: September 21, 2017 Accepted: October 14, 2017 Published: October 18, 2017

Citation: Krzywinski S, Siegmund J (2017) 3D Product Development for Loose-Fitting Garments Based on Parametric Human Models. J Fashion Technol Textile Eng S3:005. doi:10.4172/2329-9568.S3-005

Abstract

Researchers and commercial suppliers worldwide pursue the objective of achieving a more transparent garment construction process that is computationally linked to a virtual body, in order to save development costs over the long term. The current aim is not to transfer the complete pattern making step to a 3D design environment but to work out basic constructions in 3D that provide excellent fit due to their accurate construction and morphological pattern grading (automatic change of sizes in 3D) in respect of sizes and body types. After a computer-aided derivation of 2D pattern parts, these can be made available to the industry as a basis on which to create more fashionable variations.

Keywords: 3D-CAD, Parametric Human Models, Mass Customization

Introduction

Despite the global division of labor and the associated outsourcing of manufacture, garments are still mainly developed in Germany or Western Europe. The reason is the know-how in pattern making that has been gained over decades, the knowledge of fashion desires and functional requirements, the long-term safeguarding of product quality and the proximity to domestic consumers. In order to ensure the competitiveness of the European garment industry also in the future, the results from research must be practically relevant and be implemented faster in product development.

In recent years the German fashion industry has made great investments to obtain up-to-date information about body proportions and body dimensions as a result of the size survey Size GERMANY and, based on these, to develop a size system that reflects the customer's current body dimensions and finds acceptance in the industry. This work has been largely completed. The stated number of sizes and variants (250 variants for men, 135 variants for women) clearly illustrates what great requirements resulting from the variety of human body shapes the garment industry has to cope with. Added to this is the abundance of different textile materials.

Although detailed information on dimensions and shapes are now available to support the model designer, the basic procedure in practice has hardly changed in the last five years. No lasting revision of the 2D design specifications has yet been made to take the sizing survey data into account. To date, most basic constructions (e.g. for blouses/shirts, jackets, dresses, skirts, trousers) are based on just a small number of body dimensions. Body shape parameters are implemented by relying on so called proportional dimensions and empiricism and are thus not reproducible. This procedure is encountered worldwide and is reflected in the country-specific standard reference works of pattern making [1-10].

Virtual fit simulation in application of software solutions such as Modaris V8 (Lectra), VIDYA (Human-Solutions Group) or PDS (Optitex) is also just starting to be comprehensively used in the industry. These simulation programs permit a digital 3D visualization of the garment by virtual sewing combined with an approximate consideration of the properties of the textile materials used. Poor fit can thus be recognized early without sewing or by sewing only a reduced number of prototypes. However, here again, constructional deficiencies are eliminated in an iterative process in the 2D CAD environment.

While other industries, e.g. the automotive and machine construction industries, have massively promoted the transition to 3D methods for years, the associated benefits of linking aesthetical and technical design during the whole design chain have hardly been exploited in the garment industry. The causes are the extreme complexity of the human shape (geometry) and the problem that garment construction constitutes an idealization of the body shape. In addition, designing in 3D requires model designers with extended knowledge. The greatest challenge of the transition to a new CAD system is the application method. The designers have become familiar with 2D systems over many years and have been trained intensively how to handle these. A full transition to a 3D method currently seems not to be implementable in the fashion industry because, on the one hand, the new generation of engineers trained at such systems just starts making its way into the companies. On the other hand, the software solutions are not yet mature enough for application-specific needs so that they do not allow efficient working methods in practical use.

Despite all deficiencies of the 2D design method which demands enormous expert knowledge in order to translate the design into wellfitting garments in 2D design environment with as few iterations as possible, this procedure is still dominant in the industry. In order to make better use of the research results, the link between digital 3D body shape data, 3D basic constructions and 2D pattern making is being investigated.

Model designers can then continue to use their usual software tools, but build their modelling steps on basic constructions that are automatically generated based on 3D body shape data or use these data to check their designs.

Therefore, solutions are being worked out to exploit the present development progress, yet allowing their adaptation to the current work environment by special tools and methods, and thus to facilitate the transition without overburdening the staff by completely new procedures.

General Approach

While the models of basic sizes (e.g. German sizes 38 to 46 for women’s wear) are often designed with good success, insecurities and the number of necessary iteration loops increase for the sets of sizes derived by pattern grading to cover the variety of sizes and body shapes. Due to the enormous time pressure placed on design departments in industrial practice, typically only few sizes are tested for fit using prototypes and live models. Poor fit and dissatisfied customers or a considerable return rate (40% to 70%) are the deplorable result.

Due to the enormous variety of models in loose-fitting women's wear and some considerable design ease in relation to the body to suit the fashion style, it makes no sense to aim at a complete 3D design.

Available 3D CAD systems are awkward to use when drawing wide skirts, sleeves, flounces or gathers and the like. The translation of such features in 2D would be complicated since the surfaces produced can only be imaged flat with considerable distortions and would therefore not result in useful pattern parts.

Researchers in this field worldwide thus agree that, in 3D, it only makes sense to design constructions with necessary wearing or comfort-related ease in relation to the body, and based on these, to automatically derive 2D patterns with proper fit. The boundary conditions apply to all basic constructions (bodices with and without darts for dresses/coats, blouses/jackets as wells as skirts and trousers). It would thus be great progress if model designers could have access to a wide size spectrum derived from body shape data and tested for fit.

Development of scalable virtual female mannequins

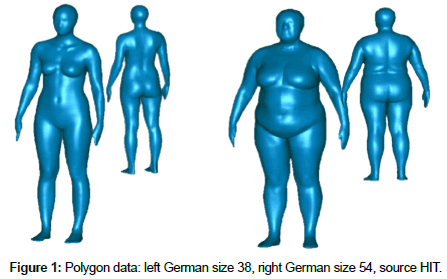

Working out 3D based basic constructions for women's wear first requires the development of virtual mannequins of variable shape that allow scaling for sizes and body shapes. The starting point is a polygon model of German size 38 (see Figure 1 left).

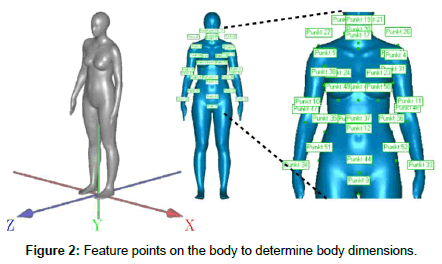

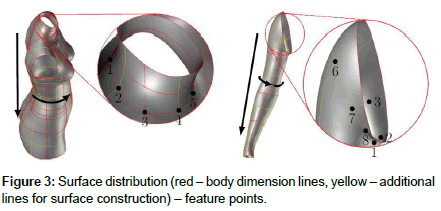

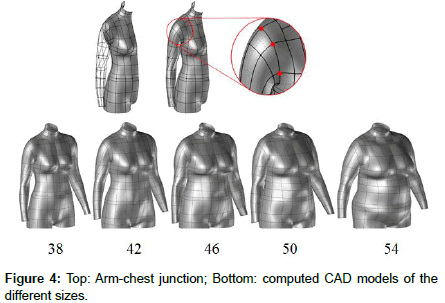

For the body-conforming mapping of these and further sizes (e.g. German size 54 in Figure 1 right) by means of spline surfaces (spline surfaces are more suitable for CAD environments), it is of enormous importance to determine the number of cutting planes in the horizontal and vertical directions as well as further dividing lines. To position the cutting planes, the feature points on the body (Figure 2) are first used to determine the body dimension lines (chest girth, waist girth, … Figure 3 red lines) or measured lengths (shoulder width) on the body. If these are not sufficient, further curves are determined to allow accurate mapping of the body shape by CAD surfaces (Figure 3 – yellow lines). The intersections of these lines are defined as cross points and used for size-specific scaling. These points are assigned “increment values” in the form of x, y, z coordinates and stored in a database so that scaling can be automatic. The cross points are linked by spline curves or surfaces to map the body surface.

By linking the CAD data with an Excel sheet where the point information is stored, it is thus possible to generate a different size at the touch of a key in a computer-aided operation (Figure 4). To be absolutely certain that the considerable change of curve and surface shapes is accurately mapped, all CAD data were verified using medium-height mannequins of available sizes.

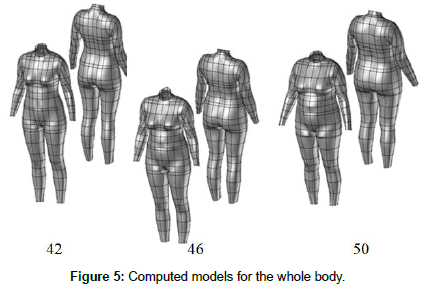

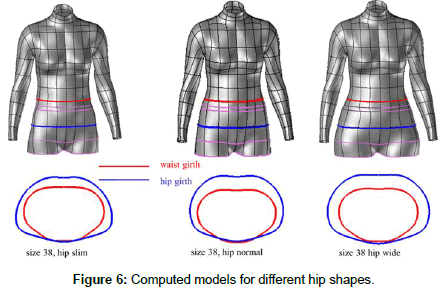

Figure 5 shows the computed spline surfaces for the whole body. The shape congruence of such complex geometries is considered to be very positive. Like it is shown in Figure 6 (slim, normal and wide) could be also generated. The cross-sections for waist and hip circumference exemplarily illustrate the morphological change of the shaped body.

Development of the construction methodology for basic constructions of women's wear

Our own investigations [11,12] and literature research [13-19] have shown that even with basic constructions the garment is not placed on the body in the form of offset curves or surfaces. To get a feeling for how garments hug the body or at what distance from the body they should be positioned, it is possible to simulate 3D basic constructions of the model size (e.g. German size 38) on the virtual mannequin. Since the flexural softness of the fabric has a significant effect on drapability and thus on the space between garment and body, a rather stiff fabric is chosen for the simulation in order to limit folds. Another possibility is to scan test subjects in well-fitting garments. In both cases the result is a polygon model. This can then be used to determine the cutting curves in the planes that are significant for the construction. In the case investigated the basic construction is sewn following a construction rule of Müller et al. [10] with only little allowances (back width 0 cm, armhole diameter 2.5 cm, chest width 0.5 cm) added to the construction lines (Figure 7).

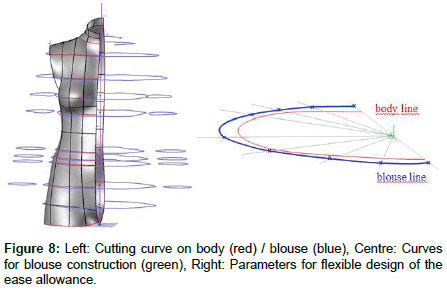

Figure 8 shows the relationship determined between blouse and body based on the cutting curves. The curves are smoothed a bit, and in the next step, they must be described mathematically, stored in the construction database and designed using parameters in order to be able to change and adapt the ease allowance automatically. To maintain the relation to the body, in the best case all feature points of every cutting curve on the body are used since the size-specific scaling is already stored there. How many and what points are used depends on the complexity of the curve (Figure 8).

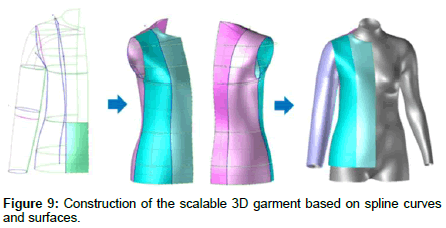

To eliminate the need to approximate the surfaces for describing the garment shape by using a multitude of regular patches, freeform surfaces are used. These can be generated with any 3D CAD software on the basis of the described curve construction. The implementation of the computational change in ease allowance, e.g. for translating the basic construction of a dress into that of a coat and this over the desired size spectrum, sets high scientific requirements. The bodice and sleeve constructions are worked out, scaled and tested for fit in separate assemblies. To do so, the interdependence of armhole curves and sleeve curves is defined and determined with positional accuracy (Figure 9).

The size-scalable enveloping surfaces for the garments are divided into pattern parts on the surface by drawing the pattern part curves. It should be noted that surfaces with considerable curvatures resulting from the body shape are divided by dividing lines or darts to get developable surfaces. The 2D pattern parts for the desired body sizes are then computed on the basis of the body shape data, eliminating the usual 2D grading. To realize the flattening procedure [20-22] it is possible to apply the industry-specific commercial software (e. g. Design Concept 3D Lectra).

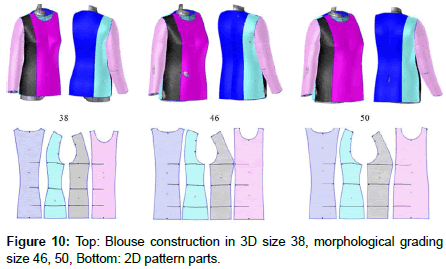

Figure 10 shows the blouse models generated in a computer operation in the sizes 46 and 50 from the parametric body model and the template in size 38. The presented models were produced based on the assumption that the space between body and blouse should remain the same for all sizes. All relevant measured lengths and feature points of the body are automatically projected onto the respective pattern parts. Markings which are required for the subsequent sewing process can also be generated in 3D. A computeraided size modification is possible at any time after fit testing. The results from fit testing are very positive. By drawing the pattern boundaries directly on the envelope surface of the blouse different model variants can be created very quickly (Figure 11).

Conclusion

Summarily, it should be emphasised that the construction of the required garment envelope and pattern part definition is only necessary once when scalable mannequins are used. When the mannequin is changed in size, the virtual garment automatically adapts to this change.

Up to now the garment pattern making can be accomplished through the empirical experience of the designer because there is a lack of correlation between virtual body and product model and garment pattern. This deficiency can be overcome through direct construction on the virtual mannequin so as to rationalise the product development significantly. The desired research outcomes will provide an indispensable basis of an effective new technology for the fit-relevant construction of loose-fitting garments and thus of further acceleration of the textile chain. The automated generated 2D patterns are available to the industry for the revision of the currently valid construction regulations. The significant benefit of the research results is that 3D body information, which is developed on the basis of extensive series measurements, is incorporated into product development without the need for clothing companies to switch to a 3D development environment. This can make it much easier for designers to work. Based on the results of the research project, it enables optimal garment fitting corresponding to the different body types for the target groups. This leads to increased customer satisfaction, a higher purchase frequency and thus contributes significantly to ensuring the market success in this segment. As product development remains one of the most cost-intensive processes, the targeted mission of modern technology will bring about savings of up to 60% of the currently necessary labour time.

Acknowledgment

The IGF research project BG09446/13 of the Forschungsvereinigung Forschungskuratorium Textil e. V., Reinhardtstr. 12-14, 10117 Berlin is funded through the AiF within the programme for supporting the “Industrielle Gemeinschaftsforschung (IGF)” from funds of the Federal Ministry of Economics and Technology (BMWi) by a resolution of the German Bundestag.

References

- Kopp E, Rolfo V, Zelin B, Gross L (1991) How to Draft Basic Patterns. (4th Edtn), Fairchild Fashion & Merchandising Group, New York.

- Stanley H (1991) Flat Pattern Cutting and Modelling for Fashion. Stanley Thornes, Cheltenham, England.

- Kirchdörfer E, Reusch (1995) Konstruktionsgrundlagen für Damen- und Mädchenbekleidung. Bekleidungstechnische Schriftenreihe Band.

- Nakaho Y (1995) Clothing Construction. Asakura Publishing Co., Ltd., Tokyo, Japan.

- Rosen S (2004) Patternmaking: A Comprehensive Reference for Fashion Design. Pearson/ Prentice Hall, US.

- Liu RP (2005) Pattern Making Theory & Technology. China Textile & Apparel Press, Beijing, China.

- Matiko M (2006) Clothing Construction. China Textile & Apparel Press, Beijing, China.

- Aldrich W (2008) Metric Pattern Cutting for Women’s Wear. (5th Edtn), Blackwell, Pub, Oxford.

- Armstrong HJ (2009) Patternmaking for Fashion Design, fifth edition, Pearson Prentice Hall, US.

- Müller M (2017) Cut designs for dresses and blouses. Rundschau publishing house, Germany.

- Hlaing EC, Krzywinski S, Rödel H (2011) Development of 3D Virtual Models and 3D Construction Methods for Garments.

- Hlaing EC (2013) Development of Reproducible Methods of Construction for Loose-fitting Garments on the Basis of 3D Virtual Female Models. University Dissertation, Dresden, Germany.

- Wang CL, Wang Y, Yuen MF (2002) Featured based 3D garment design through 2D sketches. Computer-Aided Design 35: 659-672.

- Petrak S, Rogale D (2006) Systematic representation and application of a 3D computer-aided garment construction method, Part I: 3D garment basic cut construction on a virtual body model. International Journal of Clothing Science and Technology 18: 179-187.

- Kim S, Park CK (2007) Basic garment pattern generation using geometric modelling method. International Journal of Clothing Science and Technology 19: 7-17.

- Andreeva M (2017) Innovative technology of visual parametric design of clothes from 3D models to ready-made patterns and layouts. Sewing Industry.

- Liu YJ, Zhang DL, Yuen MMF (2010) A survey on CAD methods in 3D garment design. Computers in Industry 61: 576–593.

- Huang HQ, Mok PY, Kwok YL, Au JS (2012) Block pattern generation: From parameterizing human bodies to fit feature-aligned and flattenable 3D garments. Computers in Industry 63: 680–691.

- Kuzmichev V, Surikova GI, Surikova OV, Gnidenko AV (2013) Designing of light industry products in CAD (CAD of clothes). Verlag ID FORUM.

- Ermanni P, Endruweit A (2007) Composites Technlogien, Kap. Textile Halbzeuge. S. 1-45, Vorlesungsskript, Eidgenössische Technische Hochschule Zürich.

- Krzywinski S (2005) Verbindung von Design und Konstruktion in der textilen Konfektion unter Anwendung von CAE. Habilitationsschrift, Fakultät Maschinenwesen, TUD press, Germany.

- Weeën F (1991) Algorithms for draping fabrics on doubly-curved surfaces. International Journal for Numerical Methods in Engineering 31: 1415-1426.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi