Review Article, J Fashion Technol Textile Eng S Vol: 0 Issue: 5

A Comparison of the Requirements of Tent Fabrics for Various Usages

Yavuzkasap Ayakta D1* and Ozek HZ2

1YUNSA Worsted & Wollen Production and Training Co. R&D Center, Cerkezkoy, Tekirdag, Turkey

2Namik Kemal University, Department of Textiles Engineering, Corlu, Tekirdag, Turkey

*Corresponding Author : Duygu Yavuzkasap Ayakta

YUNSA Worsted & Wollen Production and Training Co. R&D Center, Cerkezkoy, Tekirdag, Turkey

E-mail: dayakta@yunsa.com

Received: September 24, 2017 Accepted: October 09, 2018 Published: October 15, 2018

Citation: Ayakta YD, Ozek HZ (2018) A Comparison of the Requirements of Tent Fabrics for Various Usages. J Fashion Technol Textile Eng S5:006. doi:10.4172/2329-9568.S5-006

Abstract

Tents, once, had been served as a daily life shelter for ancient tribes, are still in use today. It is also widely used as a temporary accommodation for sports, entertainment and emergency shelter or some mobile professional activities. In this study, a short history of tents is presented and current standards for camping tents are evaluated. The requirement of tent fabrics In accordance with the design and the usage is reviewed.

Keywords: Tent Fabric; Designation of Tents; Specification of Camping Tents

Introduction

Textile materials have been used for sheltering since the ancient times. During the prehistoric ages, these materials were used for primitive habitations and tents as alternative to caves. Surfaces made by straws or bast fibres, animal hides and felts were the very first materials to be used. It is known that the earliest technologies primarily used human hands as the main tools in addition to the some artifacts made of stone, bone etc. These facilities were sufficient to obtain such materials. The first reliable traces of human dwellings, found from as early as 30,000 years ago, follow precisely these logical principles. There is often a circular or oval ring of stones, with evidence of local materials being used for a tent-like roof [1,2].

One may assume that these materials were the early primitive versions of today’s functional textiles materials. The first aim of the tents was to fulfill the necessity of a safe shelter, by providing a protection in the harshest conditions. Today the usage of the tent is not the shelter as it once was. Advances in textiles and lightweight structures and cultural change have resulted in the provisions of amenity and comfort. Although modern tents successfully meet the practical purposes for which they are designed, they are hardly the type of structures that many people would now enjoy living in as they are no longer actually designed for long-term inhabitation. Whereas once tents were intended for daily use, now they are used only in situations where the need for shelter is of immediate and of short duration. Nowadays, tents are used for sports, entertainment, temporary professional and commercial activities and more importantly for emergency shelter, hospital or storage for survivors and casualties during catastrophic events. The durability and functional characteristics of tent fabrics are very important. There appears very limited number of work on these topics. One study examines the mechanical properties [3], another study analysis the water resistance and water permeability performance [4]. There are also work on flame retardancy performance of tent fabrics [5,6]. Cotton canvas was traditional material for tents but recently high performance nylon and polyester are used.

Designation of Tents

Tents are portable shelters with a cover and a structure. The specification and component parts from tents are described by International Standards. In general, camping tents are specified by the ISO 5912 [7]. It is stated by this standard that tents should be made from fabrics meeting the requirements specified in ISO 10966:2011 [8]. This standard describes Sports and recreational equipment, Fabrics for awnings and Specification, but it currently withdrawn. The ISO 8936:2017 [9] is another standard relevant to textiles fabrics which describes Awnings for leisure accommodation vehicles and Requirements and test methods. Vocabulary and list of equivalent terms of camping tents and caravan awnings are given by the ISO 7152: 1997 [10]. Tents for emergency/refugee shelters and military usages are not included in these standards. A guide to the use of family tents in humanitarian relief is published by the United Nations [11].

Specification of Camping Tents

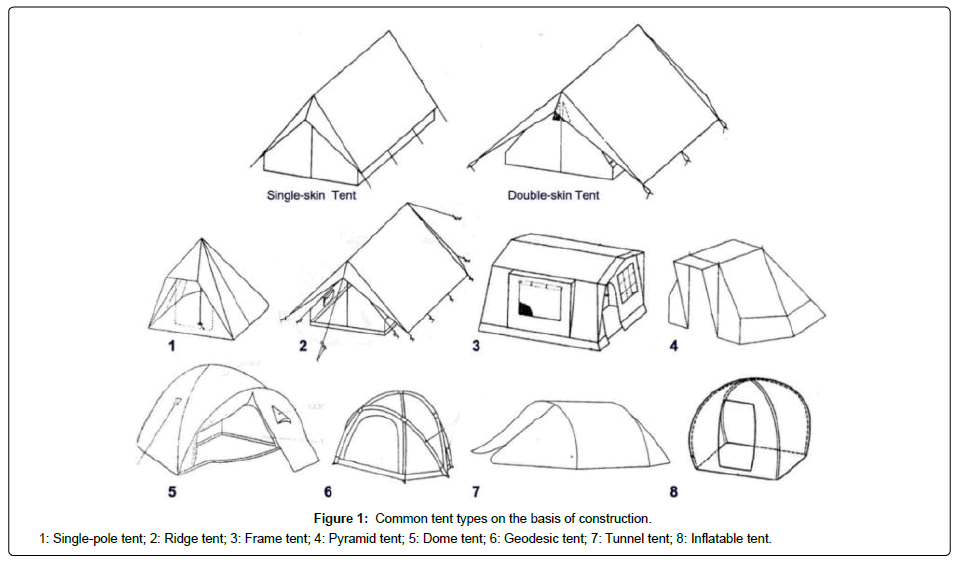

In general, tents are classified on the basis of usage and design form according to the ISO 7152 [10]. Three different usages are specified, and there is a variety of different basic designs and shapes of tent (Figure 1).

Tent Types in accordance with the usage

Sleeping tent (type S): tents which are in principle used for sleeping purposes.

Touring tent (type T): tent for residential purposes suitable for repeated pitching and striking down.

Residential tent (type R): tent for residential purposes for longterm pitching and not designed for regular pitching and striking, i.e. spring until autumn without snow load.

Tent Types in accordance with the design

Single-pole tent: tent with only one, generally vertical, pole.

Ridge tent: tent with at least two poles and a horizontal or sloped ridge between them.

Frame tent: tent of which the frame assembly is self-standing, with steep walls and roofs with a shallow angle under which it is possible to stand upright.

Dome tent: hoop tent generally in the form of a hemisphere.

Pyramid tent: tent generally in the form of a pyramid.

Hoop tent: tent in which one pole at least is in the form of a hoop.

Single-hoop tent: tent with a single pole in the form of a loop.

Tunnel tent: tent with parallel hoops, generally in the form of a half-cylinder or a truncated cone.

Geodesic tent: dome tent with at least three flexible poles which cross over to form triangles.

Inflatable tent: tent of which the principal structure is made of inflatable tubes.

Requirement of Fabrics for Camping Tents

While tent fabrics are preferred to be lightweight for easy transportability, a reasonable performance is expected to face up to natural environment conditions. It may also be expected to have waterproof, UV resistant, antibacterial, insulative or breathable characteristics. The actual choice of dye colours and the level of its saturation both critically affect illumination within the tent as well as night times to heat loss and daylight heat gain (Tables 1 and 2). Aiming for a medium level of neutral lighting is considered as a good compromise. Good light transmission is also accompanied by increased UV penetration and hastened degradation of the fabric, therefore the choice of color should be selected, accordingly. Dope dyed filament yarns may be considered for better fastness property made from certain polymers cannot be dyed after they have been made. Pigment must be incorporated into the 'melt' prior to the filament extrusion [12,13].

| Cat.A | Cat.B | ||||||

|---|---|---|---|---|---|---|---|

| Level 1 | Level 2 | Level 3 | Level 1 | Level 2 | Level 3 | ||

| Tear resistance i.a.w. | Outer tent, C | 10 | 10 | 15 | 10 | 15 | 20 |

| ISO 13937-2 | Ouıter tent, UC | 10 | 10 | 15 | 15 | 20 | 25 |

| inner tent | |||||||

| Ground sheet | 12 | 12 | 15 | 12 | 15 | 20 | |

| Breaking strength | Outer tent, C | 250 | 300 | 400 | 300 | 400 | 500 |

| 250 | 300 | 400 | 300 | 400 | 500 | ||

| ISO 13934.2 | Inner tent | 150 | 200 | 300 | 200 | 300 | 400 |

| 250 | 300 | 400 | 300 | 400 | 500 | ||

| Plastic window | 100 | 150 | 200 | 100 | 150 | 200 | |

| Resistance to penetration by water i.a.w ISO 811 [kPa] | outer tent, C | 15 | 15 | 25 | 15 | 20 | 30 |

| Groundsheet | 15 | 30 | 50 | 15 | 30 | 50 | |

| Weatherability i.a.w. ISO 105 B04 | Outer tent, C | 3 | 3-4 | 4 | 3 | 3-4 | 4 |

| 3 | 3-4 | 4 | 3 | 3-4 | 4 | ||

| (measured against blue wool) | Plastic window | 3 | 3-4 | 4 | 3 | 3-4 | 4 |

| Colour fastness i.a.w. ISO 105-X12 (wet test) | Outer tent, C | 3-4 | 4 | 5 | 3-4 | 4 | 5 |

| Outer tent, UC | 3-4 | 4 | 5 | 3-4 | 4 | 5 | |

| 3-4 | 4 | 5 | 3-4 | 4 | 5 | ||

| Groundsheet | 3-4 | 4 | 5 | 3-4 | 4 | 5 | |

| Plastic window | 3-4 | 4 | 5 | 3-4 | 4 | 5 | |

| Resistance to puncture i.a.w. EN388 [N] | Groundsheet | 10 | 15 | 15 | 10 | 15 | 20 |

| *UNCOATED (UC)-COATED (C), i.a.w: in accordance with | |||||||

Table 1: Minimum requirements for tent fabrics of different categories and levels.

| Property | Level A | Level B | Level A | Level B | Direction | Test method |

|---|---|---|---|---|---|---|

| Breaking Strength [daN] | 60 UC | 60 UC | 60 UC | 60 UC | warp and weft | ISO 1421 |

| 65 C | 65 C | 65 C | 65 C | ISO 13934-1 | ||

| Tear Resistance [daN] | 1,0 UC | 0,5 UC | 1,0 UC | 0,5 UC | warp and weft | ISO 13937-1 |

| 1,5 C | 1,2 C | 1,0 C | 0,8 C | |||

| Resistance to penetration by water [hPa] | 30 UC | 22 UC | 30 UC | 25 UC | ISO 811 | |

| 150 C | 80 C | 150 C | 80 C | ISO 1420 |

Table 2: Minimum physical requirement for outer fabrics of camping tents.

To achieve a practical level of waterproofness even the most tightly woven synthetic fabrics must be coated or laminated with a continuous waterproof film. In the coating process, the liquid coating substance is scraped by the fabric. The most common fabric coating polymers are polyurethane (PU), polyvinylchloride (PVC), and acrylic (polyacrylonitrile PAN). These are highly UV resistant but insufficiently flexible, particularly at low temperatures. PVC is an excellent barrier to water vapor but it is heavy. It is also particularly inflexible at low temperatures and its production and disposal are extremely harmful for the environment. Thus, polyurethane (PU) is the right coating of choice for nearly all backpacking tent fabrics. It has good resistance to wet-flexing and cold-cracking, is relatively light-weight. For a PU coating to have reasonable durability in prolonged tropical humidity or environmental dampness it must have good resistance to hydrolysis. Properly specified, well-cared-for, highquality PU coatings can last many years.

The other increasingly common waterproof fabric finishes is silicone elastomer. It may be applied to both faces of the fabric, or just on one face (which becomes the outside). Silicone rubber is widely used in various industries as fluid seals. It is highly waterrepellent, elastic, UV and temperature stable. At first glance it is the perfect coating except it is slow to completely cure so production time and cost are high. It also has poor fire-retardant properties and there are no thermo-plastic (hot-melt) or contact adhesives that stick to it. However, a serious disadvantage of fabrics that is coated with both sides of silicone elastomer is that accidental damage cannot be repaired with adhesive tapes.

Membranes which are produced by a wide range of polymers are advantageous in case of waterproof and breathable feature. The most common membranes used for tent laminations are PU and ePTFE (silicone). Membrane film thickness can be very accurately controlled and very high levels of waterproofness achieved with quite thin (and light weight) membranes. They also tend to have better tear strengths than polymer coated ones. The addition of extra functional features and the method of application are determined on the basis of the specific requirements of tent fabrics.

The fabrics used in camping tents are divided into two weight categories as A and B.

Category A is light weight tents having a mass of ≤ 2,5 Kg per sleeping slot.

Category B is standard weight tents having a mass of>2,5 Kg per sleeping slot.

Specific requirements for safety, performance and fitness for use of camping tents are described in detail by the ISO 5912:2011 [7]. The fabrics for tents are specified in accordance with inner or outer use. In some cases, specific type of fabrics is used for ground and roof parts. The inner fabrics for awnings and camping tents are not directly exposed to the influence of weather in practical use while the outer fabrics are. Much stronger and functional fabrics are used as outer such as coated fabric. They, usually, are treated with film-generating substances in order to permanently close the gaps between yarns or fibres thereby increasing the resistance to penetration by water.

The fabrics for tents are also graded in relation to the weather conditions. Three levels are defined:

Level 1

Tents designed for infrequent and short-term use. Although it is rain resistant, they are expected to be used mainly in fair weather such as summer camping.

Level 2

Tents designed for use in mainly moderate weather conditions such as reasonably wet and windy weather conditions.

Level 3

Tents designed for use in all weather conditions such as mountaineering, expeditions, snow-loading or extended residential use.

Conclusion

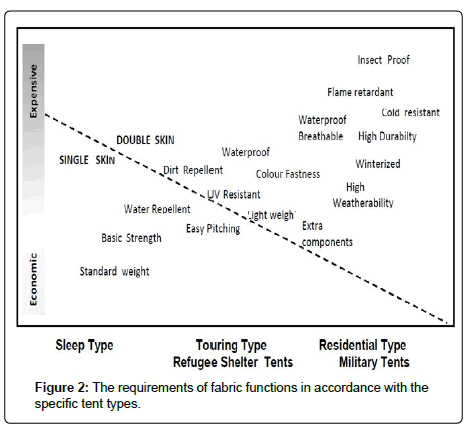

Fabric selection of a specific tent application depends on the performance requirements imposed by the end use and/or the desired aesthetic characteristics of the end user, with consideration of cost. The required functions of tent fabrics are given in Figure 2 in accordance with tent type in relation to the cost. Tents for residential usage including refugee shelters and military tents are expected to make with fabrics having many functions such as breathability, flame retardancy and insect resistance.

References

- http://www.historyworld.net/wrldhis/PlainTextHistories.asp?historyid=ab27

- https://tr.scribd.com/doc/151866419/Evolution-of-Primitive-Dwellings

- Baoqing Y, Jinming Z, Yi Q, Zhihua L (2015) The mechanical properties and wearability of the jacquard fabrics with differential density for tents. Asia-Pacific Energy Equipment, Engineering Research Conference.

- Faleev AG, Katanaeva ES, Filatov YN (2017) Water resistant and vapor-permeable, material based on electrospun fluoroplastic membranes for special purpose textile items. Fiber Chemistry 49: 227-230.

- Alexander S, Keller AS, Raju NP, Webster TF, Stapleton HM (2014) Flame retardant applications in camping tents and potential exposure. Environ Sci Technol Lett 1: 152−155.

- Alexander S, Keller AS, Raju NP, Webster TF, Stapleton HM (2014) Flame retardant applications in camping tents and potential exposure. Environ Sci Technol Lett 1: 152−155.

- Ali Yaras A, Er E, Celikkan H, Disli A, Alicilar A (2016) Cellulosic tent fabric coated with boron nitride nanosheets, J Ind Text

- ISO 5912 (2011) Camping tents.

- ISO 10966 (2011) Sports and recreational equipment, Fabrics for awnings - Specification

- ISO 8936 (2017) Awnings for Leisure Accommodation vehicles, Requirements and Test Methods.

- ISO 7152 (1997) Camping tents and caravan awnings — Vocabulary and list of equivalent terms.

- Chen Y, Yu J, Chu C (2004) The Present and Developing Trend of the Tent Fabrics. J Technical Textiles.

- Fan Xiaodong, Wu Qiang (1998) Development of Tent Fabrics. J Technical Textiles.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi