none, J Fashion Technol Textile Eng Vol: 0 Issue: 0

Basic of Protective Textile and Its Properties and Application

Mohit M Jain*

Student of B.Tech textile, Svkm’s NMIMS Shirpur, India

- *Corresponding Author:

- Mohit M Jain

Student of B.Tech textile, Svkm’s NMIMS Shirpur, India

E-mail: mohitjain7745@gmail.com

Received Date: June 13, 2021; Accepted Date: July 15, 2021; Published Date: July 22, 2021

Citation: Jain MM (2021) Basic of Protective Textile and Its Properties and Application. J Fashion Technol Textile Eng 9:7. 214.

Copyright: © All articles published in Journal of Fashion Technology & Textile Engineering are the property of SciTechnol, and is protected by copyright laws. Copyright © 2021, SciTechnol, All Rights Reserved.

Abstract

A significant segment of the technical textile market is that of Protective Clothing (PC), which is receptive to new products and suppliers. Protective clothing can be divided into various groups, including, clothing against heat, flame, mechanical impacts, cold, chemical substances, radioactive contamination, and protective gloves against mechanical and thermal hazards. The focus of protective clothing is more on sophisticated needs, and in situations where the hazards or risks are present that have the potential to be life threatening, or pose considerable potential for injury or damage to the person working in hazardous situations. The Nuclear, Biological, and Chemical (NBC) lightweight over boots provide more than twenty four protection against chemical warfare (CW) agents, and are fully antistatic, meeting EN 344 and DIN 4843 standards, and with three adjustable, all butyl, elastic loop closures. A common objective of the protective clothing industry is the creative and innovative application of available technology, and much of the technology involved is among the most sophisticated available, and the end uses being complex and of great value.

Keywords: Textile; Clothing; Protective

Introduction

The primary objective of body armor research is to develop a low cost, lightweight, wearable garment system with ballistic impact resistance. Body armor standards require that a projectile should be stopped under ballistic impact, and that the penetration depth into a clay witness backing the armor should not exceed 1.73 inches. If penetration depth exceeds this value, a wearer can incur serious blunt trauma. Aramid (Kevlar) and ultra-high molecular weight polyethylene (Spectra R) have been introduced as base materials for ballistic protection. These high-performance fibers are characterized by low density, high strength, and high energy absorption. However, to meet the protection requirements for typical ballistic threats, approximately 20–50 layers of fabric are required. The resulting bulk and stiffness of the armor limits its comfort, and has restricted its application primarily to torso protection. Apparels made of natural fibers not only influence favorably some of the physiological factors of the body but also ensure safety during sunny days protecting against hazardous ultraviolet radiation. Ultraviolet rays emitted by the sun and thinner ozone layer or enlarging ozone hole create together a high risk to the humans. For this reason clothing should guarantee protection to the user against higher level of UV radiation. The protection is strictly connected with structural parameters of cloth like its density, thickness, clearance as well as color and finishing agents (e.g., Rayosan, Solartex, Ciba-Fast-P). The type of fiber is also important especially in case of raw fabrics (non-dyed) [1].

Definition: Protective clothing does not mean the same to all people. As in most discussions of technical products, we must first define our subject. While all clothing is protective to some degree, our concern is not with routine needs, such as clothing for warmth, rainwear, or routine work clothing. Our focus is on more sophisticated needs, protection in situations where hazards or risks are present that have the potential to be life threatening or pose considerable potential for injury or damage to the person working in and around the hazard. In some cases, such as clean rooms, we may be equally concerned about protecting the product we are working with as well as the worker.

Protective fabric categories: Over the years, ITA has divided the market for PC into the following segments. This has since become in general, how the industry as a whole look at the market.

1. Protection from extreme cold

2. Ballistic and mechanical protection

3. Protection from radiation

4. Protection from harmful particulate matter

5. Bacterial/Viral protection

6. Clean room - Protecting delicate items in manufacture

7. Protection from harmful chemicals

8. Protection from extreme heat and/or fire

There are other areas, high pressure for instance, but the above list covers most of those concerns where products have been, or are being developed. We all look at each segment individually.

1. Extreme cold: Cold protection requires products with high degrees of insulation, the least bulk, good/relative comfort, and still allowing good dexterity for doing useful work. Still air is a poor conductor of heat, so insulation requires a layer of still air between the skin and the source of the heat or cold. The best insulation has always come from down, the fine underside and neck of goose or other fowl feathers. Industry has attempted to emulate the insulating characteristics of down, with varying degrees of success, using all types of fiber-fill, high-loft, high bulk products to create still air insulating space. Among the most successful products are those that include blends of course and very fine microdenier fibers. 3M’s Thinsulate® and Albany International’s Primaloft® are examples of products that use combinations of micro fine and regular” sized fibers to create many air holding cells. Then fibers absorb less than 1% of their weight in moisture, making the products, in this regard, superior to down where dampness is present [2]. Used in combination with other “hitech” materials, good insulation with lower bulk and weight can be achieved in extreme situations (Figure 1).

2. Ballistic/mechanical: This area includes soft body-armor, various cut and/or slashes hazards, such as chain saws, sheet metal, glass, knives or other sharp edges, and stab and puncture resistant materials. The most significant advance in the ballistic area has been the development and use of pararamids, such as DuPont’s Kevlar, to replace nylon as a ballistic barrier. This very high strength fiber, the same as used in tire cord, composites, and the like, is used in soft body armor by loosely stacking layers (16+) of (usually) filament aramid fabric, each providing coverage and progressive resistance to bullet or fragment penetration. Similar technology with rigid composites result in superior lightweight “hard” armor as well, for uses such as helmets and replacement of heavier steel armor plate areas such as vehicle and aircraft armor [3].

A recent development, Spectra Shield® (AlliedSignal) involves the use of Spectra®, Allied’s high strength HDPE fiber. A warp beam containing parallel multifilament yarns is drawn through a thermoplastic polymer and laid side by side, in sheet form, atop a similar bundle of yarns at a 900 angle. Yarn layers can be stacked and cured for semi-rigid and rigid armor. With many yarns and virtually no voids or openings, as may be present at the interstices (crossing points) of a woven fabric, the matrix provides high levels of protection, including to angular penetration.

3. Radiation: Concern in this area involves protection from radioactive particulate matter or fall-out protection. Most garments used are impermeable to particulates to prevent ingestion and/or skin contact and absorption into the body tissues. The penetration and permeation protection is offered by special co-polymer coatings or laminates with broad spectrum chemical resistance. The base fabric acts as carrier and/or a strength member to provides durability consistent with the use and the coating. Typical would be polyethylene coated fabrics onto Tyvek or other non-wovens such as polyester or olefin. The US’s Savannah River Site plutonium plant uses a suit made of such special coated fabric for tritium protection. The encapsulating suit is made of polyester fabric laminated on each side with layers of film consisting of co-polymer extrusions of CPE/EVA/PVDC (Saran)/EVA. Other suits of Saran/CPE supported with nonwoven or unsupported are also used.

4. Particulate matter: Particulate protection refers to the hazards typified by those involved with asbestos or lead abatement, a large volume but relatively low dollar/unit application. US usage figures peaked in excess of 90 million yards 2, with declines seen as buildings were cleaned and/or reduction or delays in enforcement were encountered. Recent studies have even questioned whether the danger is as great as previously thought, even in schools. Lead abatement and paint particulate protection has taken up some slack. The asbestos abatement market is a finite one since asbestos production has essentially stopped in the US and all asbestos to be removed from existing buildings, in the US at least, will be done within the next 4-5 years. At one time, it was estimated that we would spend 25 dollars to remove what it cost 25 cents to put in. A Fortune magazine article a few years ago estimated that as much as $100 billion would be spent in the US over the next 20 years to remove asbestos in schools and other public buildings; probably a high figure, but a lot of contractors jumped in the business. Rethinking the actual or real danger, and what exactly we should do about removing it, has lessened the amounts spent, but large amounts were and are involved.

5. Bacterial/viral: The PC area of medical textiles, as per our definition, has been fueled by the concerns related to the AIDS virus, hepatitis, and other life threatening transmittable diseases. Barrier fabrics, laminated or coated woven and non-woven fabrics with sophisticated co-polymer extrusion coatings, are being developed, along with anti-bacterial finishes for use by hospital and medical personnel, emergency responders such as ambulances, firemen, and police. A good example of the work being done in this area is DuPont’s Biowear® materials for protection against blood borne pathogens. Anti-bacterial fabrics are of interest in this area. Most finishes are topical, with varying degrees of longevity. A Japanese product, Bactekiller® (Kanebo), has a bactericide built into the polyester fiber at the extrusion process. The bacteria killing agent, based on zeolite salts, stays in the fiber, even when dyed, processed, or washed. A unique feature is that the nature of the bactericide medium (sodium aluminosihcate) makes it applicable where dehumidifying, deodorant, and absorbent properties are important. Other products are also available.

Requirement: Faster, stronger, lighter, safer ... these demands are constantly being pushed upon today’s researchers and manufacturers, including protective clothing - routine or specialized. High performance and high temperature resistant fibers aid enormously in allowing products to meet these challenges. The markets and products which are facilitated by the use of these fibers go far beyond the scope and awareness of most people. This paper intends to provide a solid overview of the definitions, properties, products and end uses associated with some of the most common high performance and high temperature resistant fibers used today. It is stressed that not all high performance materials a represented [4].

Apparels made of natural fibers not only influence favorably some of the physiological factors of the body but also ensure safety during sunny days protecting against hazardous ultraviolet radiation. Ultraviolet rays emitted by the sun and thinner ozone layer or enlarging ozone hole create together a high risk to the humans. For this reason clothing should guarantee protection to the user against higher level of UV radiation. The protection is strictly connected with structural parameters of cloth like its density, thickness, clearance as well as color and finishing agents (e.g., Raisin, Solartex, Ciba-Fast-P). The type of fiber is also important especially in case of raw fabrics (non-dyed).

Main types of protective fabric

1. Human safety

2. Agro safety.

1) Human safety:

a) Head protection: (Hard hats, helmets, sun hats) shall be provided where there is a risk of injury to the head, such as a person struck on the head by a falling object, a person may strike his/her head against a fixed object, there may be inadvertent head contact with electrical hazards (Figure 2).

b) Eye protection: (Goggles, safety glasses) shall be provided where a risk of eye injury exists. Typical hazards might include flying particles, dust, splashing substances, harmful gases, vapours, aerosols, and high intensity radiation from welding operations (Figure 3).

c) Hearing protection: (Ear plugs, ear muffs) shall be provided where a risk of noise induced hearing loss exists. The need for hearing protection may be assessed through noise monitoring or surveys (Figure 4).

d) Respiratory protection: (Respirators, face masks, cartridge filters) shall be provided where there is a risk of airborne contaminates. This will minimise the risk to of exposure to an atmosphere that is or may be injurious to health (Figure 5).

e) Hand protection: (Gloves, gauntlets) shall be provided where there is an identified hazard associated with a potential for hand injury. A list of hazards shall be compiled for each workplace and suitable hand protection obtained to minimize risk (Figure 6).

f) Protective footwear: (safety boots, gumboots, enclosed shoes) shall be provided where the nature of the work exposes the employee to a medium to high risk of injury to feet, eg occupations such as workshop/maintenance and gardening staff.

g) Body protection: (high-visibility garments, thermal wear, overalls, aprons, safety harnesses) shall be provided to minimise risk of injury occurring to the body. Examples may include those who are required to work outdoors and are exposed to the sun’s rays for continuous periods in a day. Direct exposure of the skin to UV radiation from outdoor work shall be minimized by providing hats, long sleeves/trousers and an adequate supply of sunscreen (Figure 7).

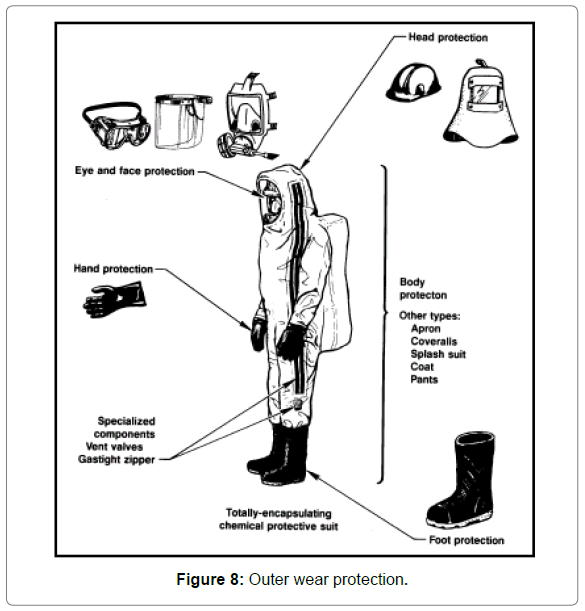

h) Outer wear: (high visibility safety vests, reflective vests, fluoro jackets) shall be provided to highlight the worker in the area often used where there is a risk of injury associated with working on or near roadways or near moving traffic or moving plant (Figure 8).

2. Agro safety

Agrochemicals and the Environment: Agrochemicals are essential to help in intensifying crop production and to reduce the effects of pests and parasites on farm animals. These agrochemicals can however be easily washed into the streams or infiltrate the soil, eventually contaminating ground water reserves (Figure 9).

Have you ever wondered why you might have at times experienced stomach problems after taking water? This experience could be associated to the consumption of polluted water. Chemical pollutants pose major threats to public health through poisoning. In both fresh and sea water, algae can multiply rapidly or bloom when there is a sudden increase in water nutrients particularly nitrates and phosphate. This contaminated algae in turn become an important source of food for fresh water and marine animals [5]. Toxic algal blooms have a variety of effects on public health. In some cases people experience signs of acute diarrhea and even death when they eat fish or animals contaminated by toxins. Harmful algal bloom has begun to increase in many parts of the world as a result of an increase in nitrate and phosphate-rich fertilizers and sewage to wash into the open seas and rivers through runoff.

Fibre properties and their application

Meta-aramid: Nomex® (DuPont), TeijinConex®, TeijinConex HT® (Teijin): Perhaps the best known and most widely used of the aramid fibers (Nomex is familiar to many), meta-aramids are best known for their combination of heat resistance and strength. In addition, meta-aramid fibers do not ignite, melt or drip; a major reason for their success in the FR apparel market. In comparison to commodity fibers, meta-aramids offer better long-term retention of mechanical properties at elevated temperatures [6]. Meta-aramids have a relatively soft hand and tend to process very similarly to conventional fibers, giving them a wide range of converted products. Meta-aramids are available in a variety of forms, anti-stat, conductive, in blends (with other high performance fibers), etc. TeijinConex HT high tenacity type meta aramid has significantly higher tensile strength of other meta-aramids. This high strength allows it to bridge the gap between meta-aramid and para-aramid fiber when strength is the primary concern (Tables 1 and 2).

| M-aramid Properties | Value |

|---|---|

| Tenacity g/de | 3.8-7.2 |

| Elongation (%) | 25-40 |

| Limiting Oxygen Index | 30 |

| Chemical resistance | Mild-Good |

| Operating temperature | 4000 F |

Table 1: Meta-aramid: Nomex® (DuPont), TeijinConex®, TeijinConex HT® (Teijin).

M-Aramid Fabric Form |

Application |

|---|---|

| 1. Needle felt | Automotive |

| Business machine parts | |

| Cushion material | |

| Hot gas filtration | |

| Safety & Protective clothing | |

| Thermal insulation | |

| Thermal spacers | |

| 2. Woven fabric | Hot gas filtration |

| Loudspeaker components | |

| Reinforcement: composites and rubber | |

| Safety & Protective clothing | |

| Thermal insulation | |

| 3. Wet-laid nonwoven | Business machine parts |

| Battery separators | |

| Heat shields | |

| 4. Dry laid nonwoven | Business machine parts |

| Electrical insulation | |

| Heat shields | |

| Hot gas filtration | |

| Laminate support base | |

| Thermal spacers | |

| 5. Spunlace nonwoven | High temperature filtration |

| Safety & Protective clothing | |

| Laminate support base. |

Table 2: Applications for Meta-aramid Fabrics.

Para-aramid: Kevlar® (DuPont), Twaron® (Acordis), Technora® (Teijin): Due to their highly oriented rigid molecular structure, para-aramid fibers have high tenacity, high tensile modulus and high heat resistance. Para-aramid fibers have similar operating temperatures to meta-aramid fibers, but have 3 to 7 times higher strength and modulus, making them ideal for reinforcement and protective type applications. There are two types of para-oriented aramid fibers:

• Homo-polymer - Kevlar and Twaron

• Co-polymer

Although para-aramids are high in strength, there is some problem with chemical resistance. Homopolymer para-aramids have relatively weak resistance to strong acids and bases. Kevlar and Twaron, for instance, cannot be bleached with chlorine and are often not approved for food handling in protective gloves. The fine surface structure of Technora copolymer allows it to have much higher chemical resistance. Kevlar has new forms with increased strength and improved properties (Tables 3 and 4).

| Properties | Value |

|---|---|

| Tenacity g/de | 22 - 26 |

| Modulus g/de | 460-1100 |

| Elongation | 2.4 – 4.4 |

| Continuous operating temperature (0 F) | 375 |

| Limiting Oxygen Index (LOI) | 25 - 28 |

| Chemical resistance | Mild - Good |

Table 3: Para-aramid: Kevlar® (DuPont), Twaron® (Acordis), Technora® (Teijin).

Form |

Form Application |

|---|---|

| Needle felt | Cushion material |

| Safety and protective clothing | |

| Thermal insulation | |

| Thermal barriers | |

| Woven fabric | Reinforcement: composites and Sporting goods |

| rubber | Thermal insulation |

| Mechanical rubber goods | |

| Safety and protective clothing | |

| Ballistic application | |

| Wet-laid nonwoven | Friction materials |

| Heat shields | |

| Yarn | Reinforcement: composites and rubber |

| Sewing thread | |

| Ropes and cables | |

| Safety and protective clothing | |

| sewing thread |

Table 4: Application of Para-aramid: Kevlar® (DuPont), Twaron (Acordis), Technora® (Teijin).

Fluorocarbon fibers (PTFE): Teflon (duPont), Toyoflon (Toray): PTFE (polytetra fluoroethylene) fibers offer a unique blend of chemical and temperature resistance, coupled with a low friction coefficient. PTFE is virtually chemically inert, and is able to withstand exposure to extremely harsh environments. The coefficient of friction for PTFE, the lowest of all fibers, makes the fiber suitable for a wide range of applications such as bearing replacement material and release material when stickiness is a concern [7].

The fibers low friction coefficient, as well as their low tensile strength, makes PTFE fibers difficult to process, and difficult to blend with other fibers. PTFE sewing thread is ideal for a number of PC and harsh applications. The material is also made into breathable, porous membranes laminated to fabrics for protective uses (Tables 5 and 6).

PTFE Properties |

Value |

|---|---|

| Tenacity g/de | 2 |

| Elongation (%) | 25 |

| Limiting Oxygen Index (LOI) | 95 |

| Chemical resistance | Excellent |

| Friction coefficient | 0.2 |

| Operating temperature (0F) | 500 |

Table 5: Fluorocarbon fibers (PTFE): Teflon (duPont), Toyoflon (Toray).

PTFE Form |

Application |

|---|---|

| Needle felt | Automotive |

| Bearing replacement | |

| Hot gas filtration | |

| Release fabrics | |

| Woven fabric | Conveyor belts |

| Mechanical rubber goods | |

| Gasket tape | |

| Wet-laid nonwoven | Battery separators |

| Heat shields | |

| Liquid filtration | |

| Monofilament | Release fabrics |

| Filtration fabrics | |

| Yarns | Mechanical rubber good |

| Sewing thread | |

| Membranes | Safety and Protective |

Table 6: Application of PTEE fiber.

PPS: Ryton® (Amoco/Successor), Procon® (Toyobo), Toray PPS® (Toray): Polyphenylene sulfide fibers combine moderate temperature resistance with excellent chemical resistance. PPS fibers also have very good flame resistance thanks to their high LOI. The low moisture regain of PPS often takes away from its use in protective apparel; the fiber has an uncomfortable hand, but the good chemical resistance makes it very attractive for Industrial applications, especially for filtration (Tables 7 and 8).

PPS Properties |

Value |

|---|---|

| Tenacity g/de | 3.5 – 4.5 |

| Elongation (%) | 32 - 49 |

| Limiting Oxygen Index (LOI) | 34 |

| Chemical resistance | Very Good |

Table 7: PPS: Ryton® (Amoco/Successor), Procon® (Toyobo), Toray PPS® (Toray).

Form |

Application |

|---|---|

| Needle felt | Hot gas filtration |

| Woven fabric | Liquid filtration |

| Laundry materials | |

| Rubber industries |

Table 8: Application of PPS fiber.

Melamine Basofil (BASF): Basofil has recently entered the high temperature fiber market, one of the newest fibers to do so, and has made a rapid impact. Compared to fibers with comparable properties, its low cost is an advantage and should result in its being evaluated in a number of areas. Based on melamine chemistry, Basofil offers a high operating temperature and a high LOI and typically targets hot gas filtration and safety and protective apparel markets. Because of its variable denier and staple length, low tensile strength, and difficulty in processing, Basofil is generally blended with stronger fibers such as aramids [8]. It is more often used in needled products or yarns made from wrapped spinning techniques, though recent advances have led to satisfactory ring spun yarns, blended with other fibers, such as para-aramids, suitable for weaving into firemen’s turnout gear. This development may lead the way to its adoption in other areas (Tables 9 and 10).

Basofil Properties |

Value |

|---|---|

| Tenacity g/de | 2.0 |

| Elongation (%) | 18 |

| Limiting Oxygen Index (LOI) | 32 |

| Chemical resistance | Mild - Good |

Table 9: Melamine: Basofil (BASF).

Form |

Application |

|---|---|

| Needle felt | Hot Gas Filtration |

| Thermal Insulation | |

| Woven Fabric | Safetyand ProtectiveApplications |

Table 10: Application of basofil fiber.

PBO: Zylon (Toyobo): Poly-phenylene benzobisoxazole is another new entrant to the high performance organic fibers market. The only entrant thus far, Toyobo’s Zylon has outstanding thermal properties and has almost twice the tensile strength of conventional para-aramid fibers. Its high modulus makes it an excellent candidate for composites reinforcement. Due to its high LOI, PBO has over twice the flame retardant properties of meta-aramid fibers. PBO is still in its pilot plant stages, with commercial production just coming on stream (Tables 11-12).

PBO Properties |

Value |

|---|---|

| Tenacity g/de - 42 | |

| Modulus g/de | 1300 |

| Elongation (%) | 3.5 |

| Continuous operation temp. (OF) | 550-600 |

| Limiting Oxygen Index (%) | 68 |

| Chemical resistance | Mild-Good |

Table 11: PBO: Zylon (Toyobo).

Form |

Application |

|---|---|

| Woven Fabric | Reinforcement composites and |

| Rubber | Sporting goods |

| Needle felt | Thermal shields |

| Heat shields | Aluminum spacers |

Table 12: Application of PBO fiber.

PBI: PBI (Celanese): Polybenzimidazole is an organic fiber with excellent thermal resistant properties and a good hand. PBI does not burn in air and does not melt or drip. The high LOI coupled with its good chemical resistance and good moisture regain make PBI an excellent fiber for fire blocking end uses such as safety and protective clothing and flame retardant fabrics. Its physical properties are relatively low, but PBI is processed on most types of textile equipment [9].

It blends well with other materials such as carbon and aramid fibers and is most often done for performance reasons as well as cost. PBI has had significant success in the fireman’s apparel market where, blended in a 60/40 para-aramid/PBI mixture, it has become the standard “premium” material. PBIs characteristic gold color blends well with other materials for a pleasing appearance. Its main drawback is its very high price over $70 per pound (Tables 13 and 14).

PBI Properties |

Value |

|---|---|

| Tenacity g/de | 2.7 |

| Modulus g/de | 32 |

| Elongation (%) | 29 |

| Continuous operation temp (OF) | 482 |

| Limiting Oxygen Index (%) | 41 |

| Chemical resistance | Good - Excellent |

Table 13: PBI: PBI (Celanese).

Form |

Application |

|---|---|

| Needle felt | Thermal insulation |

| Safety and protective clothing | |

| Fire blocking | |

| Woven Fabric | Thermal insulation |

| Safety and protective clothing |

Table 14: Application of PBI fiber.

Polyimide (PI) P-84 (Inspec): P-84 is a polyimide fiber developed by Lenzing AG (Austria) and now produced and marketed by a spin-off company, Inspec Fibres GmbH in Austria. P-84 provides a high operating temperature with very good flame retardant properties and good chemical resistance. P-84 fiber touts a unique multi-lobal irregular cross section. This irregular structure offers greater surface area than a conventional round cross section, and has achieved widespread recognition for P-84 fiber in the hot gas filtration market. Due to its high price however, actual use of P-84 in the filtration market is limited to areas where extreme emission controls are necessary. It has also made inroads in the protective clothing market, especially in Europe (Tables 15 and 16).

P-84 Properties |

Value |

|---|---|

| Tenacity g/de | 4.2 |

| Elongation (%) | 30 |

| Continuous operation temp. (OF) | 500 |

| Limiting Oxygen Index (%) | 38 |

| Chemical resistance | Good |

Table 15: Polyimide (PI): P-84 (Inspec).

Form |

Application |

|---|---|

| Needle felt | Thermal insulation |

| Safety and protective clothing | |

| Woven Fabric | Thermal insulation |

| Safety and protective clothing |

Table 16: Application of P-84 fiber.

Carbon Precursor: Lastan (Asahi): Lastan is a flame-retardant fiber made by pyrolytic carbonization of a modified acrylic fiber. Carbon precursor fibers are partially carbonized fibers which transform into carbon or graphite fiber when they undergo further carbonization in an inert atmosphere at high temperature. Carbon precursor fiber combines a high operating temperature with excellent flame resistance. Since this fiber is relatively weak and has limited abrasion resistance, it is often blended 50%/50% with para-aramid fibers creating a strong durable product still having an LOI of 45. Due to its soft hand, Lastan fiber is desirable in apparel applications as well as certain industrial application (Tables 17 and 18).

Lastan Properties |

Value |

|---|---|

| Tenacity g/de | 2 |

| Elongation (%) | 15 |

| Continuous operation temp. (OF) | 392 |

| Limiting Oxygen Index (%) | 60 |

| Chemical resistance | Mild |

| Electrical resistance | 108 -1010 W cm |

Table 17: Carbon Precursor: Lastan (Asahi).

Form |

Application |

|---|---|

| Woven Fabric | Welding blankets |

| Aluminized fabrics | |

| Thermal barriers | |

| Safety and protective clothing | |

| Needle felt | Needle felt $ Thermal barriers |

| Safety and protective clothing |

Table 18: Application of Lastan fiber.

Carbon fiber: PAN (polyacrylonitrile) and Pitch based: There are different categories of carbon fibers based on modulus, tensile strength, and final heat treatment temperature. In the carbonization process, temperature exposures range from 10000 C to 20000 C, each different level of exposure creating a different property for the fiber. For example, high-modulus type is processed at 20000 C, 15000 C for high strength type, and 10000 C for low modulus and low strength type. The main carbon fibers are made from polyacrylonitrile (PAN) based and pitch based, and are well known for their composite reinforcement and heat resistant end uses (Tables 19 and 20).

Carbon Fiber Properties |

PAN | PITCH |

|---|---|---|

| Tenacity g/de | 18-70 | 14-30 |

| Modulus g/de | 1640 - 3850 | 1000-5850 |

| Elongation (%) | 0.4-2.4 | 0.2-1.3 |

| Continuous operation temp. (OF) | 570 - 1000 | 570 - 1000 |

Table 19: Application of Carbon fiber: PAN (polyacrylonitrile) and Pitch based.

Form |

Application |

|---|---|

| Woven Fabric | Aircraft and aerospace |

| Automotive | |

| Sports & recreational equipment | |

| Marine | |

| General engineering | |

| Yarn/Fiber | Reinforcement composites and |

| Rubber | Filtration |

Table 20: Application of Carbon Fiber.

Conclusion

• High performance fibers and high temperature resistant fibers offer numerous advantages over traditional materials. Higher strength, lighter weight, higher operating temperatures and flame-retardant ability are some of the most prominent features of these fibers.

• These outstanding properties create opportunities to manufacture products that historically could not be made due to technical constraints. The protective clothing area is one of those markets.

• Each of these fibers discussed have their limitations. It is not as easy to take these materials “off the shelf” except for a few well-distributed ones. Surely, some are more readily available than others -- the aramids, HDPE, for instance -- but most are less so and should be considered as engineering or specialized materials to be used where their properties are paramount. Review thoroughly each fiber for the properties it brings to the product.

References

- Cunniff P M (1992) An analysis of the system effects in woven fabrics under ballistic impact. Text Res J62: 495-509.

- Addendum B (2001) NIJ STANDARD–0101.04 Ballistic resistance of personal body armor.

- Bazhenov 3 S (1997) Dissipation of energy by bulletproof aramid fabric. J Mater Sci 32: 4167-4173.

- Lee Y S, Wetzel E D and Wagner N J (2003) The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. J Mater Sci 38: 2825-2833.

- Lee D I and Reder A S (1972) in TAPPI Coating Conference Proceedings: 201.

- Hoffman R L (1974) Discontinuous and dilatant viscosity behavior in concentrated suspensions. II. Theory and experimental tests. J Colloid Interface Sci 46: 491-506.

- Barnes H A (1989) Shear‐thickening (“Dilatancy”) in suspensions of nonaggregating solid particles dispersed in Newtonian liquids. J Rheol33: 329-366.

- Bossis G, Brady J F (1989) The rheology of Brownian suspensions. J Chem Phys 91: 1866-1874.

- Farr R S, Melrose J R, Ball R C (1997) Kinetic theory of jamming in hard-sphere startup flows. Phys Rev E 55: 7203.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi