Research Article, J Fashion Technol Textile Vol: 10 Issue: 5

Development of Sustainable Technique for developing Antibacterial Face mask Effective for Protection from Viruses

Smriti Agarwal*

Department of Textile and Fashion, Mody University, Lakshmangarh, Prayagraj, India

*Corresponding Author: Smriti Agarwal, Department of Textile and Fashion, Mody University, Lakshmangarh, Prayagraj, India, E-mail: smritiagarwal@gmail.com

Received date: 18 February, 2022, Manuscript No. JFTTE-21-50372;Editor assigned date:21 February, 2022, PreQC No. JFTTE-21-50372(PQ);Reviewed date: 07 March, 2022,QC No. JFTTE-21-50372;Revised date: 18 April, 2022, Manuscript No. JFTTE-21-50372(R);Published date: 02 May, 2022, DOI: 10. 4172/2329-9568.1000252

Citation: Smriti A (2022) Development of Sustainable Technique for developing Antibacterial Face mask Effective for Protection from Viruses. J Fashion Technol Textile Eng 10:5.

Abstract

The people are very familiar with the fact that the clothes are the home for bacteria to grow and multiply. This results mainly in the transmission of communicable diseases and in general the skin-related diseases such as rashes, allergies, irritation, infections, lesions, and foul smell. Antimicrobial clothing treated with natural/herbal material is becoming popular as the first barrier towards bacterial activity in an eco-friendly way.

In past years, very few to nil efforts have been made for the development of antimicrobial fabric using medicinal plant's aqueous extracts from used Natural Recourses. In Rajasthan many plants with medicinal properties are available, the same plants are grown on self no need to give more water, care, and fertilizer also. Such types of plants are very beneficial for developing herbal products. The textile sector is a very large sector to produce harmful gases and these are very harmful to Environment as well as responsible for pollution and different health issues like skin irritation, breathing problems, etc.

Textile Ministry is very serious to stop textile industries wastage, very strict rules are also developed by Ministry and strict advisory is there to use sustainable techniques for textile production. In this paper researcher work on basically two objects, one on developing Sustainable technique and another one developing the herbal antibacterial mask which protects from different viruses also provide a good level of protection from Nobel virus covid -19. 2nd Novel virus Pandemic nature is that it spread around the world very rapidly and affected approx. 11.8 million individuals worldwide and has resulted in more than 5.45 lakh death (till 9th July 2020). In India approx. 7.95 lakh Confirmed cases and 21,638 deaths due to COVID-19 were reported till 10th July 2020. Spreading of Coronavirus in person to person by several ways viz. droplets, aerosolized transmission, surface transmission, and fecal-oral. Covid-19 can affect multiple organs in the body.

Rajasthan is the third largest and one of the slow-developing states of India, Rajasthan literacy, technical development, economic growth, and other many aspects are responsible for the indication of backward stats of the Rajasthan.

The Rajasthan state is situated in the north-western part of India between 23o 3' and 30o 12 N latitude and 69o 30' and 78o 17 E longitude and comprises an area of about 34227 Sq Km. A striking geological feature of the Rajasthan state is the Aravalli range which divides the state into two main physiographic regions, the 2/3 sandy arid plain which is unproductive, Thar desert, and 1/3 eastern fertile region rich in vegetation. About 80% of the population lives in villages and tribal of different communities form nearly 50% population of the state. Due to the constant association with the forest environment the tribal have accrued considerable knowledge of the plants and their utility, especially for medicinal purposes. In the Rajasthan hub number of textile industries working in the field of dyeing, printing, and various types of cotton production.

The present paper is an attempt to prepare dyeing and printing technology based on a sustainable production process with antibacterial properties develops in fabric by dyeing process. The researcher used two Natural resources as a natural dye-cottage level using indigenous and traditional techniques. The treated fabric will be having antimicrobial properties and when this fabric will be used for the preparation of different products it will be far better than the product prepared from the normal untreated fabric as it will protect from microbes hence the paper will be taken up with the following objectives:

Objectives: The sustainable technique development with different standard parameters for sustainable dye. Preparation of Antibacterial face mask and face cover through application of Sustainable dye.

Keywords: Natural dye, Color, Cotton fabric, Opium dyel, Mordents, Optical density, Dyeing, Dye, Liquor, Dye bath, Mordent

Introduction

Colors play a very essential role in any sector of production houses science of color is a very broad area of study that has many aspects including color and vision, color, and preferences, color therapy, color psychology, color chemistry, etc. Color chemistry is directly related to color development, dyeing, printing, and many more. Textile and fashion Industries are using different types of colors pigment, dye, synthetics, etc. dying after dyeing industries throw the wastage in rivers, ponds or fields, the economy of textile and fashion market based on color and their tints and shades but also responsible for pollution increased day by day. Synthetic dye is toxic and the environment unfriendly. Many drawbacks of synthetic dye have inspired environmentalists to look for an eco-friendly product. Therefore, natural dyes now give more importance. Many kinds of research were undertaken for the extraction of dyes from different natural coloring sources. Textile Ministry strictly declares by the offense low to stop such types of activity. Synthetic dye is not only harmful to the Environment also responsible for skin disease, breathing problems, etc. Experts continuously work to develop good quality of sustainable dye sources from our nature, such types of dye known by the Natural dye. Researchers develop many types of natural dye by using wastage of flowers, leaves, etc. In this area of work to the development of natural dye my suggestion to researcher and production houses before production of natural dye, if you used natural resources first grant permission from NBA (National Biodiversity Authority) without permission of NBA invention is not beneficial for the commercial market.

Natural Dyes are available in nature by the different sources; Leafs, flowers, bark, rust, send, animal skin, etc. India is a religious country in temples hub amount of flowers are used in pooja and the next day destroys all. The researcher approximately collected 5 famous temples in Jaipur in one day 65 kg flowers are available after puja this point indicates natural dyes availability are not an issue also many aspects are very positively worked behind the promote utilization of the natural dye in the textile and fashion sectors. Natural dye is poor fastness properties mordants are used the improve the fastness properties, Natural and chemical mordents are available Investigators selected according to the need for different shades development. The process of natural dye has many steps all steps are very important for the fastness properties of dye and desired shade development.

Opium -the botanical name is Papaver somniferum is used for the study, opium is a flowering plant consider under the medical plant and deal with forest department as well as medical plant board, the herb is used for treating high blood pressure and mental disorders, mainly roots are used in medical science with the properties of Antimicrobial, Antifungal, Anticholinergic 4 Chronic recurrent fever, sores in the mouth, and also vapor use as steam it brings relief from toothache or cold, etc. (Figure 1).

Figure 1: Head of the poppy.

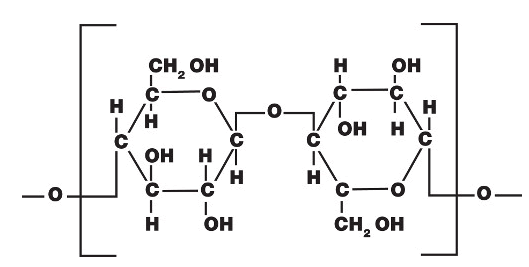

Cotton fabric production is in India from the back of Indian history, cotton fabric is not only preferred for study on production view it's also very comfortable in every session and chemical-physical properties are very good, available at every cost that's easily approachable for all income groups. The chemical structure of the cotton fabric has cellulose molecules in the form of 1,4 and 1,6 glycosides with connected anhydroglucose unit with a high degree of polymerization and crystallinity, this property provides high straight of the fabric (Figure 2).

Figure 2: Cellulose is a macromolecule made up of anhydroglucose unit connected by 1, 4 oxygen bridges with the polymer repeating unit being anhydro-beta-cellulose.

Material and Methods

Degumming of the material

Ethanol use for the degumming of the fabric. 30 mi/100 ml of ethanol use for removing the impurities from cotton fabric, then Scouring of cotton cloth was done by washing it in a solution containing 0.5 g/lit Sodium carbonate and 2 g/lit liquid soap at 50°C for 25 mins, keeping the material to liquor ratio at 1:40. The scoured cotton was thoroughly washed with tap water and dried at room temperature. The scoured material was soaked in clean water for 30 mins before dyeing or mordanting in this processor material deep in water with ethanol on up to 70oC for 30 minutes then wash the fabric in tab rinsing water and dry in sunlight for increased whiteness in the sample.

Equipment used

Weighing balance, Water/Dye bath, Colorimeter, Thermometer etc

Results and Discussions

Dye extraction

Solvent was used for maximum dye extraction, leave were collected and samples were collected and washed thoroughly with water to remove any impurities. After drying at room temperature, the leaves converted into powder with the help of hand crushing. 100 g of dye was weighed and taken in a water bath and 500 ml of solvent (ethanol-water) in the ratio of 30:100 ml. was added to it. The water bath was heated at 70°C for 30 mins. The solution was then filtered to obtain dyestuff for dying of cotton fabric. Weighed cotton cloth was treated with the mordant. Three processes of mordanting were used-pre mordanting, simultaneous mordanting, and post-mordanting. After dyeing, the dyed material was washed with cold water and dried at room temperature.

| S.No | Dyeing Variables | Selected Proportion |

|---|---|---|

| 1 | Extraction Method | Boiling Method |

| 2 | Dye concentration | 100 gm |

| 3 | Dye Extraction Time | 30 min |

| 4 | Dying time | 30 min |

| 5 | Alum | 20 gm/100 gm of cotton |

Table 1: Various variables shown in Table 1-3: optimum dye proportion for dyeing of cotton samples and fastness properties with Papaver somniferum.

Fastness tests

The dyed material was tested for light fastness, wash fastness and rub fastness. The color fastness is usually rated either by loss of depth of color in the original sample or is expressed by staining scale Light fastness was analyzed by exposing the dyed materials to direct sunlight for 9 am-5 pm, 8 hrs. The wash fastness was carried out by washing the dyed fiber with liquid soap (1 g/lit). The rubbing fastness of the dyed fiber was carried out by rubbing the fiber and checking for fading of color.

The results of the colorfastness test indicated that the colorfastness to washing for all colors was fair to good, the colorfastness to Ironing and dry-cleaning for all colors was excellent too good (Tables 2 and 3).

| Color fastness property | Ocher Simultaneous Mordanting | Yellow Post Mordanting | Near Golden yellow/Pre Mordanting | Result |

|---|---|---|---|---|

| Washing | 3 | 4 | 3 | Good to fair |

| Ironing | 4 | 4 | 4 | Good |

| Dry‑cleaning | 5 | 5 | 4 | Excellent to good |

| Rubbing | 4 | 4 | 4 | Good |

Table 2: Colorfastness test in process of washing, ironing, dry-cleaning, rubbing.

| Days | Fading with Ocher | Fading with Yellow | Fading with near Golden Yellow |

|---|---|---|---|

| Monday | 5 | 5 | 4 |

| Tuesday | 4.7 | 4.7 | 4.9 |

| Wednesday | 4 | 4 | 3.9 |

| Thursday | 4 | 4 | 3.9 |

| Friday | 3.7 | 3.7 | 3.9 |

| Saturday | 3.5 | 3.5 | 3.9 |

| Sunday | 3 | 3 | 3.5 |

Table 3: Colorfastness test throughout the week.

Costing of the Papaver somniferum dye

The cost estimation of dyeing material was calculated for dyeing per 100 gm. cotton fabric material. Dyeing of cotton fabric in yellow, Ochre, near golden yellow was less expensive due to the cost of Alum. In cost, the sheet includes various components during the process of the final product. Also, consider selling price and service price with profit margin.

Thus From the above findings, It Can be concluded that dyes extracted from opium leave dye have a range of bright, soft, even, and lustrous Colors. Dyers and craft men to increase the color range to add verity to the products can use finishing material dye. This important advantage of these dyes is, it is applicability to small scale and cottage industries for this the high technology and machinery is not necessary and easy adaptability at the procedure is possible.

Conclusion

The whole process of extraction and dyeing is eco-friendly. The obtained results have shown the dyeing potential of opium peel as a source for cotton dyeing it was found from the experimental study that, the boiling method was best from dye extraction from opium leave dye for dyeing of cotton fabric. It also observed that percentage absorption of opium Leaves dye simultaneous Mordanting method gave best (70%) absorption and post-Mordanting method was second best.

The opium leaves dye extract gave the best results with an optimum Concentration of 100 gm, in 500 ml. of water per 100 gm of the cotton sample. It found that the extraction of dye was maximum with 30 minutes boiling time. It was also observed that the sample dyed for 30 minutes gave the best result. It was observed, that 30 minutes of Mordanting gave the best results. The opium leave dye extract gave the best color on 100 gm. of each cotton sample by using 20 gm of Aluminium sulphate selected. The color obtained was shades of ochre, yellow and golden yellow with the aluminium sulphate shown good color fastness during mordant dyeing. The process of production of opium leave dye was found to be cost-effective as compared to the cost of dyes in the local market.

References

- Booth JE (1968) Principle of textile testing. Pub Buher Lond 3: 290-340.

- Joseph MI (1986) Color development and introductory textile scince. Pub Halt Poin 5:69‑89

- Agarwal S (2017) To Study of the Percentage Absorption of Natural Dye on Dyeing of Silk with Dry Pomegranate Rind. J Textile Sci Eng 6:2.

- Chanayath N, Lhieochaiphant S, Phutrakul S (2002) Pigment extraction techniques from the leaves of Indigofera tinctoria Linn. and Baphicacanthus cusia Brem. and chemical structure analysis of their major components. CMU J 1:149.

- Karim N, Afroj S, Lloyd K, Oaten LC, Andreeva DV, et al. (2020) Sustainable personal protective clothing for healthcare applications: a review. ACS nano 14:12313-12340.

[Crossref] [Google Scholar] [Indexed]

- Armentano I, Barbanera M, Carota E, Crognale S, Marconi M, et al. (2021). Polymer materials for respiratory protection: processing, end use, and testing methods. ACS Appl Poly Mat 3: 531-548.

- Shirvanimoghaddam K, Czech B, Yadav R, Gokce C, Fusco L, et al. (2022) Facemask Global Challenges: The Case of Effective Synthesis, Utilization, and Environmental Sustainability. Sustainabil 14:737.

- Babaahmadi V, Amid H, Naeimirad M, Ramakrishna S (2021). Biodegradable and multifunctional surgical face masks: A brief review on demands during COVID‑19 pandemic, recent developments, and future perspecti es. Sci Total Environ 798:149233.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi