Research Article, J Fashion Technol Textile Eng Vol: 9 Issue: 12

Effect of Opening Roller Speed of Rotor Spinning Machine on the Yarn Quality

Hosne Ara Begum1, Fahmida-E-Karim2*, Redwanul Islam3*, Abu Bakr Siddique4

1Professor, Department of Yarn Engineering, Bangladesh University of Textiles (BUTEX), Bangladesh

2Lecturer, Department of Textile Engineering, BGMEA University of Fashion and Technology (BUFT), Bangladesh

3Lecturer, Department of Textile Engineering, Ahsanullah University of Science and Technology (AUST), Bangladesh

4Professor, Department of Textile Engineering, BGMEA University of Fashion and Technology (BUFT), Bangladesh

- *Corresponding Author:

- Fahmida-E-Karim

Lecturer, Department of Textile Engineering, BGMEA University of Fashion and Technology (BUFT), Bangladesh

E-mail: fahmida_e_karim@buft.edu.bd;

Redwanul Islam

Lecturer, Department of Textile Engineering, Ahsanullah University of Science and Technology (AUST), Bangladesh

E-mail: redwan.tex@aust.edu

Received Date: December 13, 2021; Accepted Date: December 27, 2021; Published Date: January 03, 2022

Citation: Begum HA, Fahmida-E-Karim, Islam R, Siddique AB (2021) Effect of Opening Roller Speed of Rotor Spinning Machine on the Yarn Quality. J Fashion Technol Textile Eng 9:12. 232. DOI: 10.37532/jftte.2021.9(12).232

Copyright: All articles published in Journal of Fashion Technology & Textile Engineering are the property of SciTechnol, and are protected by copyright laws. Copyright © 2021, SciTechnol, All Rights Reserved.

Abstract

The yarn manufacturing process is mostly dominated by process parameters as it plays one of the most significant roles in influencing the quality of yarn. The aim of this work is to observe the quality of yarn by changing the opening roller speed for rotor spinning. Four speeds (7500 rpm, 8000 rpm, 8500 rpm, 9000 rpm) have been used to produced two different yarn count(10, 20 Ne). Sliver fineness was 0.0925 Ne. With the increase of opening roller speed the quality parameters were found improving.

Keywords: Rotor speed; Opening roller speed; Yarn quality parameter; Sliver and Yarn count

Keywords

Rotor speed; Opening roller speed; Yarn quality parameter; Sliver and Yarn count

Introduction

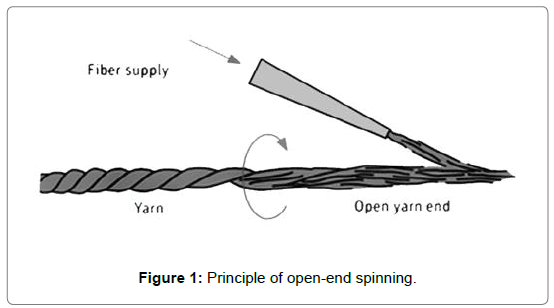

The increasing demand of yarn, rotor spinning technology is becoming more popular day by day for coarser yarn its higher productivity. Rotor yarn is produced by the principle of open-end spinning process [1]. Among all modern spinning process, it is taking a satisfactory place for coarse and medium count range. The openend principle involves a continuous flow of discrete and independent fibers towards a rotating yarn end as well as the fibers are grabbed and bound into yarn by the rolling movement [2] (Figure 1).

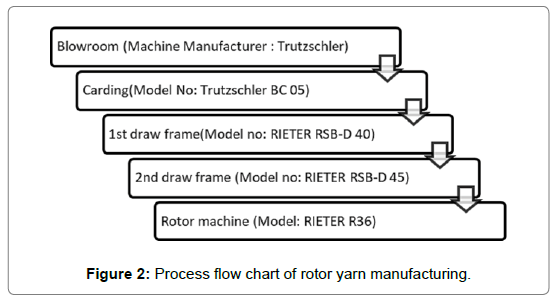

Before getting in this principle the fibers are needed to be prepared through opening, cleaning, aligned and drafted for creating slivers. To fulfill this operations blow room, carding and draw frame machines are needed for getting the input material of the rotor machine [2] (Figure 2).

Any variety of geometric measurements of the exchange channel or opening roller speed influences the air stream design, which at that point modifies the arrangement of strands streaming interior the channel [3]. An increment in opening roller speed to begin with increments and after that diminishes the spinning in-coefficient though an increment in rotor speeds perpetually diminishes the spinning-in-coefficient and yarn tirelessness. It is watched that the driving snare degree is more than the trailing snare degree [4].

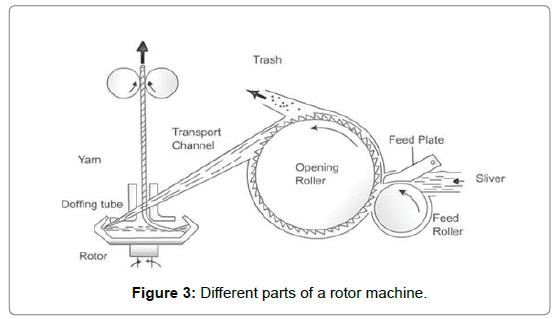

The quality of a yarn in spinning is basically determined by the process parameters. Like other spinning system the process parameters related to rotor spinning system is the number of twist multiplier, the speed of opening roller, the speed of rotor, the diameter of rotor, the angle of rotor groove etc. By working on those areas, a superior quality yarn can be achieved [5]. From the literature, it was found that rotor yarn tensile strength depends on the rotor speed, yarn twist. Increase in both parameter increases yarn strength [6]. The tensile properties of rotor yarn are also influenced by the opening roller speed. Opening roller plays an important role for making fiber individual and for supplying them to the rotor groove. The type of opening roller is fixed for different fibers from the machine manufacturer. The arrangement of rotor, opening roller and yarn manufacturing elements are shown in Figure 3.

In this work, an effort was given to find out the optimum speed of opening roller to get better quality yarn. The work was done on 10 Ne and 20 Ne yarn from the same slivers as well as using the same rotor heads.

Materials and Methods

Materials

The experiment was conducted by using Sankar-6 cotton from India for making the yarn of both counts. By using USTER HVI 1000 the properties of raw fibers were being tested according to the standard testing method [7]. The properties of raw cotton are given on the Table 1. The sliver hank was same for both count and it was 0.0925 Ne.

| Properties | Value |

|---|---|

| SCI (Spinning consistency index) | 97 |

| Moisture % | 7.6 |

| MIC (micronare) | 3.96 |

| Maturity | 0.87 |

| UHM (Upper half mean length ) | 26.16 |

| UI (Uniformity index) | 78.3 |

| SF (Short fiber index %) | 10.6 |

| Strength | 26.0 |

| Elongation | 4.0 |

| Rd (Reflectance) | 73.0 |

| +b (yellowness) | 10.1 |

| Color grade | 32-1 |

| Trash content | 64 |

| Trash ID | 6 |

Table 1: Properties of raw cotton.

Methods

The open end yarn was made by using the rotor machine, RIETER R36. The machine specification is given below Table 2.

| Points | Specifications |

|---|---|

| Machine model no | RIETER R36 |

| Opening roller type | S-40 DN 64 |

| Opening roller dia | 65mm |

| Opening roller wire angle | 24˚ |

| Rotor type | S533/U-D |

| Rotor dia | 33mm |

Table 2: Machine specification.

Spinning process: Process parameter for producing 10 Ne and 20 Ne yarn is given below Table 3.

| Name of parameters | Machine settings | |

|---|---|---|

| For 10Ne | For 20Ne | |

| Finisher Drawn sliver hank | 0.0925Ne | 0.0925Ne |

| Opening roller rpm | 7500/8000/8500/9000 | 7500/8000/8500/9000 |

| Rotor rpm | 70000 | 70000 |

| Twist per meter | 722 | 1004 |

Table 3: Process parameter for producing 10 Ne and 20 Ne yarn.

Testing of samples

Yarn unevenness and imperfections index: The produced rotor yarn samples were tested for finding out their regularity by using USTER Tester-5. IPI stands for imperfection index which is determined by the number of thick place, thin place and neps in 1000m. Unevenness change into two components, one for arbitrary dispersion of strands and the other for the variety of fiber fineness [8].

IPI (for rotor yarn) = thick place (+50%) + thin place (-50%) + neps (+280%)

Count and Strength: USTER AUTO SORTER-5 was used for determining yarn count which works with accuracy and gives direct reading in Ne. EUREKA lea strength tester was used for lea strength testing and TENSO LAB-3 was used for RKm (single yarn strength) testing.

Count strength product (CSP) = Yarn count (Ne) × Lea Strength (in lb)

Reisskilometer (RKm) = Single yarn strength (Grams force/tex) / Tex count

Result and Discussions

The variation of opening roller speed created some noticeable changes in yarn quality that is shown on the following Table 4 for 10Ne and 20Ne yarn respectively.

| Yarn Para-meters |

For 10 Ne | For 20 Ne | ||||||

|---|---|---|---|---|---|---|---|---|

| Opening roller speed | Opening roller speed | |||||||

| 7,500 rpm |

8,000 rpm |

8,500 rpm |

9,000 rpm |

7,500 rpm |

8,000 rpm |

8,500 rpm |

9,000 rpm |

|

| U% | 9.86 | 9.81 | 9.73 | 9.65 | 11.18 | 10.94 | 10.99 | 10.81 |

| IPI | 6 | 3 | 2.0 | 1 | 205 | 154.4 | 156.9 | 121.9 |

| CV% | 11.98 | 11.97 | 12.52 | 12.42 | 14.21 | 13.88 | 13.94 | 13.71 |

| RKm | 10.34 | 10.56 | 11.03 | 11.45 | 12.4 | 12.9 | 13.1 | 13.47 |

| Hairiness | 5.83 | 5.76 | 5.68 | 5.57 | 4.8 | 4.7 | 4.65 | 4.19 |

| CSP | 1472 | 1480 | 1577 | 1636 | 1879 | 1884 | 1894 | 1926 |

Table 4: variation of opening roller speed changes in yarn quality for 10Ne and 20Ne yarn.

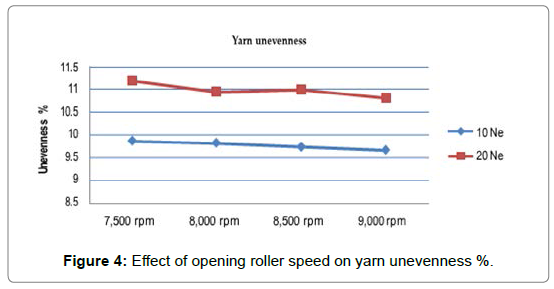

Yarn unevenness

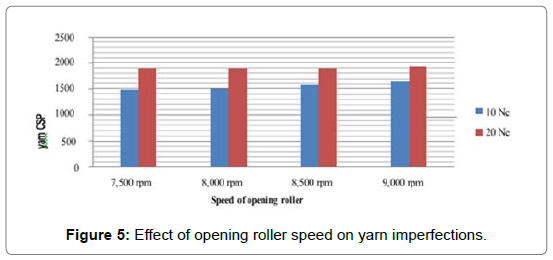

The above figure 4, it was found that yarn unevenness percentage slightly decreased for both 10 Ne and 20 Ne. It was observed that yarn unevenness value changed from 9.86 to 9.65 and from 11.18 to 10.81 respectively for 10 Ne and 20 Ne yarn. One reason why the yarn became more regular is that, the higher speed of opening roller distributes the fibers more equally on the rotor groove by doing more precise amount of opening. The value of IPI reduced from 6 to1 for 10 Ne yarn and the value decreased 205 to 121 for 20Ne yarn with the increase of opening roller speed, shown in the Figure 4. The IPI value decreased around 40% and 83% for 20Ne and 10 Ne yarn respectively. The improvement is found because of proper opening and back doubling in between the fibers (Figure 5).

Imperfections

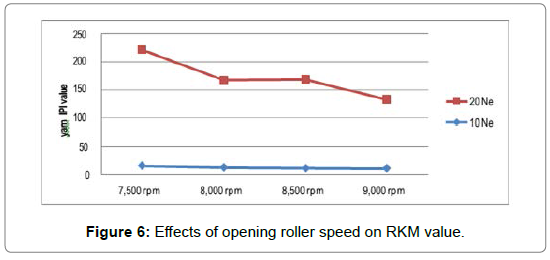

Figure 6, is describing the slightly increase of single yarn strength for both yarn counts with the increase of opening roller speed. It was noticed from the work that the change of opening roller speed in every 500 rpm effect the yarn strength to improve 2%, 4%, 4% and 4%,1.5%, 3% then the previous one for both 10Ne and 20Ne respectively.

Count and Strength

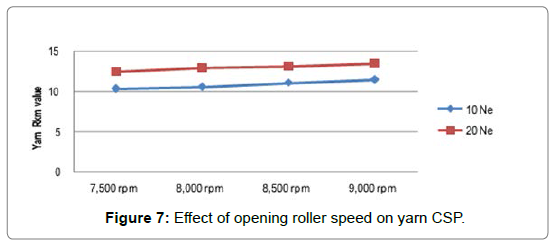

Count-strength product (CSP): Bundle yarn strength which is determined by lea strength test and the unit is CSP, increased with the increase of opening roller rpm for both yarn counts. The value improved around 11% and 2% for 10Ne and 20Ne yarn. It also noticed that the increased amount of opening roller gave more strength to the coarser yarn then the finer one. An explanation could give for this behavior is that the more yarn regularity improved the strength of yarn (Figure 7).

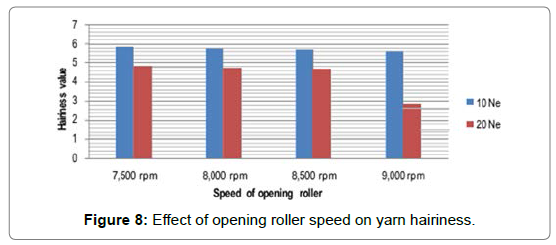

Hairiness: Yarn hairiness value also decreased with the higher opening roller speed was found from the figure 8. The value of yarn hairiness reduced around 4% and 12% for 10Ne and 20Ne respectively with the increase of opening roller speed from 7500rpm to 9000rpm. The more opening alignment of fibers due to higher speed may be responsible for creating more even wrapper fibers to bind the other fibers inside it which results less hairiness value (Figure 8).

Research Limitations

Data were collected from a particular factory. It will be more accurate if we compare the results with other factories.

Conclusion

It can be summarized from the investigation that with the increase of opening roller speed from 7500 rpm to 9000 rpm for both count 10Ne and 20Ne the parameters related to yarn quality like Rkm value, unevenness, CV% etc. improved. But with the increased amount of opening roller, the amount of trash disposition increased as well as yarn breakage rate also increased for jamming in the rotor groove.

References

- Oxenham W (2002) Current and future trends in yarn production. J Text Appar Technol Manag 2: 1-6.

- Klein W (1994) Manual of textile technology, short staple spinning series. The Textile Institute: 1.

- Kong L X, Platfoot R A (1996) Two-dimensional simulation of air flow in the transfer channel of open-end rotor spinning machines. Text Res J 66: 641-650.

- Ishtiaque S M, Kumar P (1994) Impact of rotor and opening roller speeds on configuration of fibres in yarn.

- Kumar R S (2014) Process management in spinning: CRC Press.

- Arain F A, Tanwari A, Hussain T, Malik Z A (2012) Multiple response optimization of rotor yarn for strength, unevenness, hairiness and imperfections. Fibers Polym 13: 118-122.

- ASTM D (1776) Standard practice for conditioning textiles for testing. American Society for Testing and Materials, Annual Book of ASTM Standards: 7.

- Majumdar A, Ciocoiu M, Blaga M (2008) Modelling of ring yarn unevenness by soft computing approach. Fibers Polym 9: 210.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi