Research Article, J Fashion Technol Textile Vol: 11 Issue: 3

Mitigation of Fit Issues in Men’s Stretchable Jeans: Investigating Fit Issues, Fabric Stretch Variation, and Standardising Block Patterns for Consistent Fit

Shambhavi Srivastava* and Noopur Anand

1Department of Fashion Technology, National Institute of Fashion Technology, New Delhi, India

*Corresponding Author: Shambhavi Srivastava,

Department of Fashion

Technology, National Institute of Fashion Technology, New Delhi, India

E-mail: srivastavashambhavi04@gmail.com

Received date: 22 May, 2023, Manuscript No. JFTTE-23-99635;

Editor assigned date: 24 May, 2023, PreQC No. JFTTE-23-99635 (PQ);

Reviewed date: 08 June, 2023, QC.No JFTTE-23-99635;

Revised date: 16 June, 2023, Manuscript No. JFTTE-23-99635 (R);

Published date: 23 June, 2023, DOI: 10.4172/2329-9568.1000302.

Citation: Srivastava S and Anand N (2023) Mitigation of Fit Issues in Men’s Stretchable Jeans: Investigating Fit Issues, Fabric Stretch Variation, and Standardising Block Patterns for Consistent Fit. J Fashion Technol Textile 11:3.

Abstract

The advancements in fabric technology have enabled the creation of the same garment from different fabric types, potentially resulting in a change in garment fit. With the introduction of stretch in denim, it becomes essential to analyse the impact of fabric stretch on garment fit to provide customers with better-fitting garments and increasing customer satisfaction and future purchases.

The study analyses the fit issues occurring in the stretchable jeans of a brand by taking customer fit feedback and analysing the garment measurements against its competitors. The study also maps the variation in fabric stretch percentage to ensure the correct use of measurements while manufacturing the garment.

CLO 3D is used to visually analyse the current garment as well as to improve the measurements of the jeans ultimately coming up with a standard method of adjustment of measurements for creation of jeans with fabrics with different stretch percentages.

Keywords: Comfortable; Flexible; Fabric types; Garment; Fabric technology

Introduction

Stretch in men's jeans has revolutionised the denim industry, making jeans more comfortable, flexible, and form-fitting than ever before [1]. Denim has traditionally been known for its stiff and rigid texture, which can be uncomfortable and limit movement. However, the addition of stretch fibres, such as spandex, to denim fabric has resulted in a wider range of motion and a better fit for men's jeans.

This has increased not only the comfort of jeans, but also their consumer popularity.

Several studies have emphasised the significance of proper fit in men's jeans. Denim's mechanical properties, such as elasticity and stiffness, play an important role in determining the fit and comfort of men's jeans [2]. Jeans made from a more stretchy fabric fit better and were more comfortable, whereas jeans made from stiffer fabrics fit poorly and were uncomfortable. Furthermore, fabric properties such as stretch performance have been found to influence men's jeans fit.

A proper fit in men's jeans is important not just for comfort, but also for style and functionality. Poorly fitted jeans can detract from a man's image, whilst properly fitting jeans can enhance it. Uncomfortable jeans can cause physical discomfort or harm, such as chafing or mobility restrictions. As a result, the significance of a perfect fit in men's jeans cannot be overestimated, as it can alter the garment's overall comfort, style, and utility [1,2].

The top-selling products for the brand with which the study is conducted are the Slim Fit and Skinny Fit jeans. These jeans are manufactured using fabrics categorised into three groups based on their fabric stretch percentages: Low stretch (0%-20%), Mid-Stretch (20%-30%), and High stretch (30%-40%). In order to ensure consistent fit during bulk manufacturing, the measurements of the block patterns are adjusted according to the stretch percentages of the fabrics used.

However, many customers purchasing the jeans from the brand are experiencing fit issues which lead to customers buying sizes that are either too big or too small, resulting in additional problems such as garment tearing or sagging. There is a need to mitigate the challenges that arise due to fabric stretch in order to create a block of correct fit.

Objectives

• To investigate and document the fit issues that are currently being faced with the jeans sold by the company.

• To map the variation in the fabric stretch percentages based on the industrial wash applied to the fabric.

• To create a standardised block that accounts for the fabric stretch and can be used for bulk manufacturing to ensure consistent fit.

Literature Review

Effect of elastane on physical properties of stretch denim fabric

The addition of elastane fibres significantly affects the mechanical properties of stretch denim, including tensile strength, elasticity, and bending rigidity [3]. As elastane content increases, the tensile strength decreases, but the elongation at break increases, indicating improved flexibility of the fabric. The bending rigidity of stretch denim also decreases with an increase in elastane content, indicating a more pliable fabric. Furthermore, the presence of filament yarn in the fabric reduces the tensile strength and abrasion resistance of the fabric [4].

The addition of elastane improves the stretchability of denim fabrics, with higher elastane concentrations leading to greater stretchability, although it reduces the bagging properties of the fabric [5].

Industrial denim washes used in the study

One of the key features that make denim jeans unique is the type of washes used on them. Denim washes can drastically alter the look and feel of the fabric, giving it a distinct appearance and texture. Two types of washes are mentioned in the study.

Stone wash: One of the most popular and widely used washes for denim jeans is stone washing. The process involves washing the fabric with pumice stones, which results in a faded, worn-out appearance. The level of stone wash can vary, from a light wash for a subtle effect to a heavy wash for a more distressed look. Stone washing gives denim jeans a soft and comfortable feel, making it a popular choice among consumers [6].

Towel wash combined with medium stone wash: Towel wash mixed with medium stone wash is a popular finishing technique used in the denim industry to generate a unique texture and appearance on denim jeans. The denim fabric is washed with towels or other abrasive materials to generate a soft and smooth texture, then a minor abrasion effect is created by using medium sized stones to create a slightly faded appearance. This technique is commonly used to create vintage or worn-out denim clothes [7].

Indian men’s body type and fit perception

Consumer preferences for jeans are influenced by comfort and fit, which are critical factors. Studies have investigated the correlation between men's body types and their preferences for the fit and comfort of jeans, taking into account differences in body dimensions between Indian and Western men. The studies found that factors such as body shape, waist circumference, rise, inseam length, and leg cut play a significant role in determining men's preferences for the fit and comfort of jeans. For Indian men, a low-rise waistband and a straight or slightly tapered leg are preferred [8-11].

Patternmaking with stretch denim: According to a literature review on patternmaking for men's jeans, patternmaking is crucial for achieving a comfortable and flattering fit in men's jeans [12]. The shape and size of the male body, as well as the type of fabric used, are important factors to consider in pattern making [13]. Kershaw's book on patternmaking for menswear highlights the importance of understanding male anatomy and fabrics in achieving a desired fit and silhouette [14]. Adapting conventional men's trouser blocks is necessary when creating patterns for stretch fabrics [15]. These adjustments are essential for producing well-fitting and comfortable clothing.

CLO 3D stress maps and their accuracy: The stress map is a tool on CLO 3D software that shows the stress distribution on a garment when worn by a virtual model, enabling designers to identify areas that may be prone to tearing or stretching during wear.

Accuracy is crucial to the success of 3D fit simulation technology, and several studies have been conducted to evaluate the accuracy of CLO 3D in fit simulation. These studies found that while CLO 3D can accurately capture the overall fit of garments, it may have difficulty representing fine details such as cuffs, lace, and embroidery. Nonetheless, the stress and fit maps generated by the software are useful in identifying areas of high stress in garments and providing insights into the design process [16-18].

Methodology

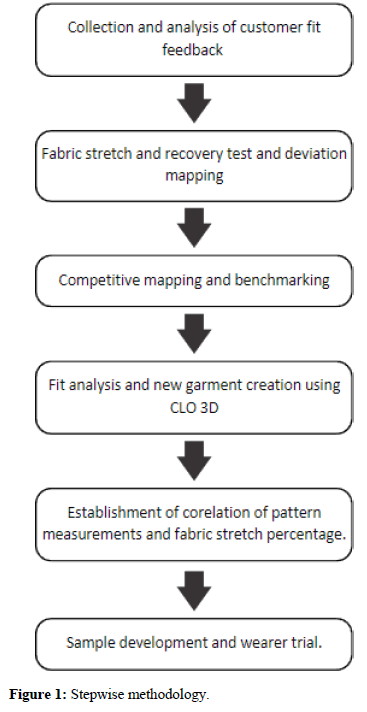

This study aims to investigate the challenges associated with creating well-fitted denim jeans using stretch denim fabric. The research design involves an initial phase of descriptive research to gain a thorough understanding of the identified gap and explore potential solutions. Quantitative data analysis techniques are later used to analyse the data, leading to informed decision-making and a conclusive outcome.

The sequential approach outlined in Figure 1 can be utilised as a model for conducting future research that seeks to gain similar insights.

Data collection

The study used a combination of primary and secondary data collection methods.

For the primary data, a survey was created to collect feedback from customers who had purchased jeans from the brand's top-selling stores in Bangalore. The survey focused on the fitting of the jeans purchased by customers at major girth measurements of the body and aimed to determine whether the customers were purchasing their usual size or whether they needed to purchase a different size to find the correct fit.

For the secondary data, key measurements of jeans from different brands were collected and mapped against the measurements of the brand's jeans to identify average and commonly used dimensions. Statistical analysis was performed on girth measurements such as waist, hip, and knee to identify major fit issues. Patterns were created and draped on the brand's standard avatar using CLO 3D to understand the fitting provided by competitor's measurements to customers.

The study also assessed the stretch percentage of different fabrics containing Cotton, Polyester, and Spandex that were subjected to different types of washes to determine the effects of the different washes on the fabrics' stretch and growth percentages. The purpose of this was to ensure that the final pattern for bulk manufacturing provides an accurate fit.

Data analysis

This study utilises various data analysis techniques to analyse collected data accurately. Descriptive statistics are used to summarise customer fit survey data, while inferential statistics are used to examine the variation in fabric stretch percentage before and after washing. Visual analytics is also used to study the fit maps of CLO 3D to identify areas for improvement or adjustment. These techniques provide a comprehensive understanding of the fit of garments, and they are utilised to ensure consistent fit when creating new garments.

Discussion

Summary and analysis of the data collected

Customer fit feedback: The results of the survey conducted gives an insight on the buying behaviour and fit preference of the customers buying from the top selling stores of the brand in Bengaluru.

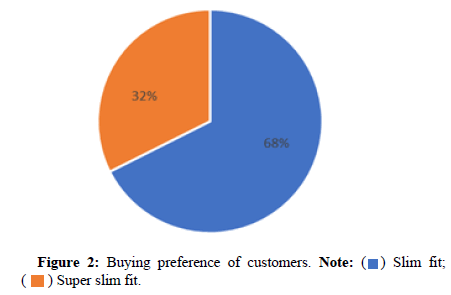

From the 40 feedback collected, 68% of the respondents bought slim fit and 32% bought super slim or skinny fit of jeans sold by the brand (Figure 2).

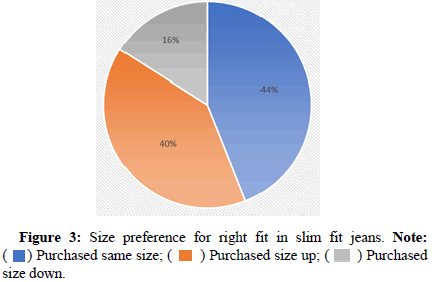

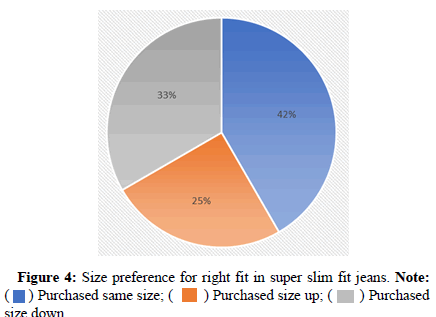

Figure 3 and 4 shows the number of customers who had to buy a size different than their usual size to find a better fit of jeans. The basic trend seemed to be that customers find better fit in slim fit jeans after sizing up and in super slim fit after sizing down.

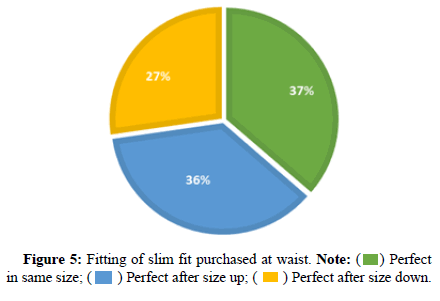

The survey also questioned the customers about the fit of the jeans purchased in key areas of the body, including the waist, hip, inner thigh, and knee. This was done in order to identify the areas of concern regarding fit issues.

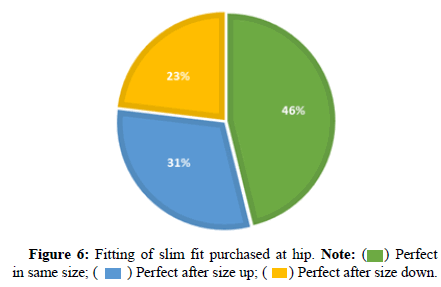

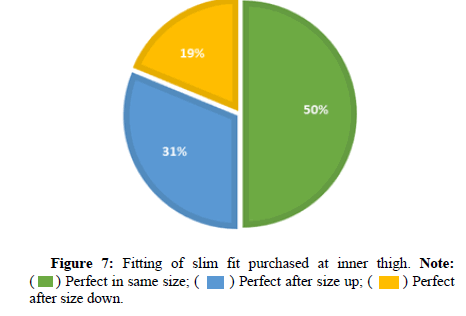

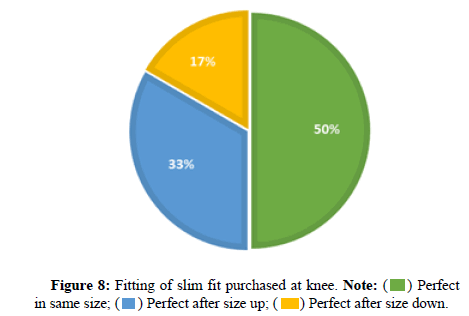

The results showed that 63% of the customers who bought slim fit jeans had issues at the waist area. This indicates that the customers had to buy a size different than the usual size they wear due to an improper fitting at the waist area. A total of 73% faced issues in both waist and hip whereas 43% customers had the fit issue in all the four areas. Figures 5-8 show the occurrence of fit issues in the areas asked.

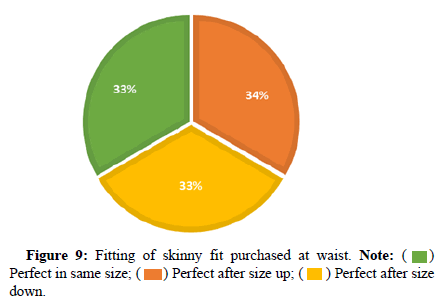

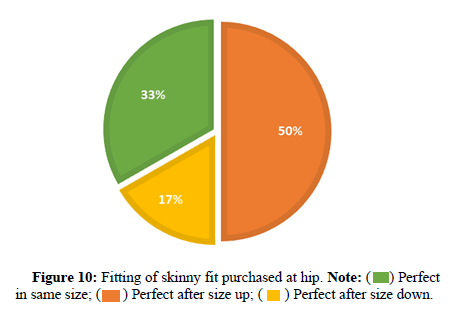

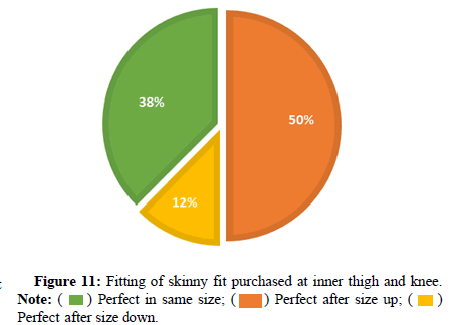

Similarly, 66% of the customers buying skinny fit jeans faced issues at the waist region (Figure 9). 83% of the total faced issues in both waist and hip region and 50% experienced issues in all the four areas of the body. Figures 10 and 11 show the issues faced by customers buying Skinny fit jeans of the brand at hip and knee and thigh respectively.

With the survey it was found that the major areas of concern for both slim and skinny fit jeans were waist and hip areas.

Stretch percentage variation mapping

In order to maintain a consistent fit for slim fit jeans, it is crucial to examine the effect of industrial washes on the stretch percentage of the denim fabric. For this purpose, three fabrics were selected with varying percentages of cotton, polyester and spandex as well as different shrinkage and stretch percentages (Tables 1 and 2). Four test specimens from each of the three fabrics were washed using four different industrial washes commonly used in the production of slim fit jeans. The stretch, growth, and recovery percentages of the test specimens were then measured using the American Society for Testing and Materials (ASTM) D-3107 (3 lbs) standard and compared to their original percentages. The results were analysed to determine the impact of the industrial washes on the stretch, growth, and recovery properties of the fabric.

| Sort | Fabric weight (Oz/yard) ± 5% | Weave | Color | Fiber composition | Warp yarn | Weft yarn | Finish EPI | Finish PPI |

|---|---|---|---|---|---|---|---|---|

| Count | Count | |||||||

| BET 1819 | 10.25 | 3/1 RHT | DK.INDIGO | 83% Cotton, 15% Polyster, 2% Spandex | 10's | 14's | 84 | 58 |

| BDP 62182 | 10.75 | 3/1 RHT | DK.INDIGO | 82% Cotton, 16% Polyster, 2% Spandex | 10's | 14's | 88 | 55 |

| BET 1105 | 10 | 3/1 RHT | SUPER DK.INDIGO | 82% Cotton, 16% Polyster, 2% Spandex | 11.2's | 16's | 92 | 58 |

Table 1: Details of the three fabrics selected for testing.

| Sort | Shrinkage% AATCC-135 | Skew movement/distortion (AATCC-179-OPTION-1) |

Stretch% (At 3 lbs Load) (ASTM D-3107 mod.) |

Finish Type | |||

|---|---|---|---|---|---|---|---|

| Warp | Weft | Stretch | Growth | Recovery | |||

| BET-1819 | 0 TO-3% | -11 ± 2% | ± 3% | 21 ± 5% | 4% | 80% | ECO FINISH |

| BDP-62182 | 0 T0-3% | -11 ± 2% | ± 3% | 33 ± 5% | 4% | 90% | MILL WASH |

| BET-1105 | 0 T0-3% | -14 ± 3% | ± 3% | 33 ± 5% | 4% | 90% | MILL WASH |

Table 2: Selected three fabrics for testing.

Results, as shown in Table 3, indicated a significant increase in stretch percentages for all fabrics after the application of industrial wash. Among the three fabric types studied, BET-1819 and BPD-62182 had stretch percentages within the range specified by the mill, while BET-1105 had a slightly higher stretch percentage that exceeded the specified range. This caused the fabric to fall within the 50%-60% stretch bracket instead of the 40%-50% range recommended by the mill. Therefore, it is recommended to verify the stretch percentages of the fabric before garment development to ensure the use of appropriate stretch bracket specification and consistent fit of garments.

| Specimen code | Type of wash | Stretch percentage in mill report | Stretch percentage before wash | Stretch percentage after wash | Difference in stretch percentage |

|---|---|---|---|---|---|

| B-18-MS | Mild stone | 21 ± 5% | 9.6 | 24.4 | 3.4 |

| B-18-DS | Dark stone | 21 ± 5% | 9.6 | 22.8 | 1.8 |

| B-18-SS | Super stone | 21 ± 5% | 9.6 | 24.4 | 3.4 |

| B-18-TWS | Towel wash+mild stone | 21 ± 5% | 9.6 | 24.4 | 3.4 |

| B-62-MS | Mild stone | 33 ± 5% | 17.2 | 32.8 | -0.2 |

| B-62-DS | Dark stone | 33 ± 5% | 17.2 | 30.8 | -2.2 |

| B-62-SS | Super stone | 33 ± 5% | 17.2 | 32.8 | -0.2 |

| B-62-TWS | Towel wash+mild stone | 33 ± 5% | 17.2 | 32.8 | -0.2 |

| B-11-MS | Mild stone | 48 ± 5% | 27.6 | 55.2 | 7.2 |

| B-11-DS | Dark stone | 48 ± 5% | 27.6 | 50.8 | 2.8 |

| B-11-SS | Super stone | 48 ± 5% | 27.6 | 54 | 6.0 |

| B-11-TWS | Towel wash+mild stone | 48 ± 5% | 27.6 | 56 | 8.0 |

Table 3: Fabric stretch percentage variation mapping with respect to the washes.

Competitive mapping of measurements

As per the survey results, slim fit jeans were purchased twice as much as super slim fit jeans. Therefore, the competitive mapping is done only for slim fit jeans. This was performed by recording the measurements at key points such as waist, hip, thigh, knee, front and back rise for the size 34 of the brand in study against its competitors and organizing them in a grid.

Comparing the brand measurements with the maximum, average and median measurements of the grid states that the brand’s jeans have a lower overall measurements with hip and waist area showing the most variation (Table 4). This suggests that customers who find the right fit at the waist in other brands may need to choose a larger while purchasing the brand XYZ’s jeans.

| POM | Maximum | Minimum | Mean | Median | Mode | Difference of brand measurement from max | Difference of brand measurement from min | Difference of brand measurement from mean | Difference of brand measurement from median | Difference of Brand measurement From mode | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Waist straight | 91.44 | 87 | 89.9 | 90.17 | 90.2 | -4.44 | 0 | -2.93 | -3.17 | -3.17 | |

| Front Rise | 28.58 | 24.13 | 26.1 | 25.5 | 25.5 | 25.4 | -3.08 | 1.37 | -0.63 | 0 | 0 |

| Back Rise | 39.05 | 36.83 | 37.5 | 37.47 | 37.5 | -2.05 | 0.17 | -0.46 | -0.47 | -0.47 | |

| High hip | 110.49 | 105.4 | 107 | 106.68 | 107 | -5.09 | 0 | -1.89 | -1.28 | -1.28 | |

| Thigh | 63 | 56.2 | 60.8 | 60.96 | 61 | 60.3 | -2 | 4.8 | 0.16 | 0.04 | 0.04 |

| Knee | 43.82 | 40 | 41.4 | 41.28 | 40.6 | -2.42 | 1.4 | -0.02 | 0.12 | 0.76 | |

| Inseam | 86.36 | 78.74 | 82.2 | 82.5 | 78.7 | -2.36 | 5.26 | 1.84 | 1.5 | 5.26 | |

| Leg opening | 41.28 | 33.66 | 36.4 | 36.51 | - | -4.28 | 3.34 | 0.62 | 0.49 | - |

Table 4: Analysis of the competitive mapping of slim fit jeans for size 34.

Competitive fit mapping using CLO 3D

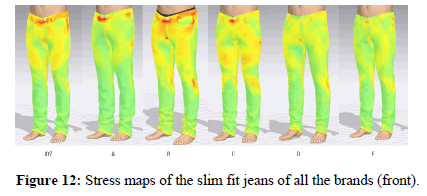

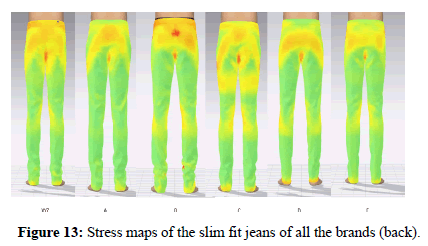

To have a visual representation of the fits of the brand in study and its competitor brands, 3D fits were created using CLO 3D on the standard model of size 34 of the brand and their stress maps were analysed.

These stress maps are colour coded according to the pressure applied on the garment by the wearer. The higher the pressure readings at a certain area, the colour changes from green (minimum) to red (maximum) and the garment becomes more prone to tearing and fabric distortion at that place. The front and back stress maps of all the brands are shown in Figures 12 and 13.

Analysing the garments and their average pressure readings at key areas-Front waist, Back waist, Hip, Thigh and Knee-shows that the brands XYZ and B have more pressure points with higher readings as compared to the other brands. Through Table 5 it is clear that the average pressure reading at the front waist of the brand in study exceeds 100 kPa and the overall pressure readings above the thigh also stays in the higher range. However, the pressure readings of the brand D and E lie in the medium pressure range and may indicate the optimal fit required for the slim fit jeans. Thus the fit maps suggest an increase in the girth measurements of the brand’s jeans to eliminate the issue of same size discomfort for the customers.

| Brand | Average Pressure Reading (kPa) |

||||

|---|---|---|---|---|---|

| Front waist | Back waist | Hip | Thigh | Knee | |

| XYZ | 109.4 | 64.25 | 52.5 | 33.53 | 28.2 |

| A | 73.41 | 40.1 | 36.4 | 31.36 | 13.3 |

| B | 85.16 | 66.07 | 75.1 | 37.5 | 41.8 |

| C | 63.97 | 43.72 | 43.8 | 30.03 | 32.5 |

| D | 34.02 | 29.1 | 48.4 | 35.5 | 24.6 |

| E | 35.27 | 35.09 | 43.7 | 29.1 | 26.9 |

Table 5: Summary of pressure readings of all the brand’s slim fit jeans.

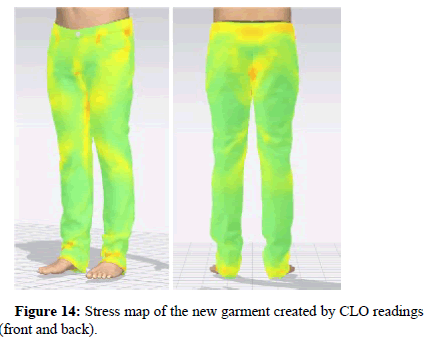

Implementation: The analysis of data acquired was used to create new specifications. The stress maps of the new garments were compared with the original before sample production. For a good fit of slim fit jeans, it is suggested that the pressure readings should be in the medium range of 33 kPa to 65 kPa, according to CLO 3D. To achieve desired fit, the central values from the average pressure readings were selected (Table 6). The corresponding measurements for the selected pressure reading were recorded, and a new garment was created using CLO 3D to evaluate its fit (Figure 14).

| Brand | Average Pressure Reading (kPa) | ||||

|---|---|---|---|---|---|

| Front waist | Back waist | Hip | Thigh | Knee | |

| XYZ | 109.4 | 64.25 | 52.5 | 33.53 | 28.2 |

| A | 73.41 | 40.1 | 36.4 | 31.36 | 13.3 |

| B | 85.16 | 66.07 | 75.1 | 37.5 | 41.8 |

| C | 63.97 | 43.72 | 43.8 | 30.03 | 32.5 |

| D | 34.02 | 29.1 | 48.4 | 35.5 | 24.6 |

| E | 35.27 | 35.09 | 43.7 | 29.1 | 26.9 |

Table 6: Central values of pressure readings taken from all the ranges.

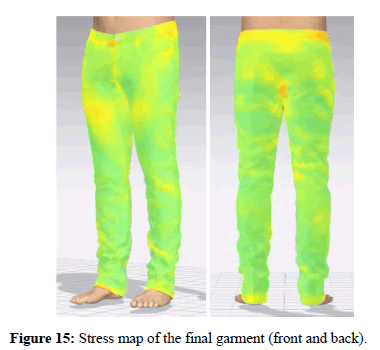

The garment made from the new measurements had a looser fit than intended as the overall pressure readings fell below the medium range (>35 kPa). Hence, modifications were made in the measurements taking the next higher pressure readings for each area into consideration (Figure 15).

The new specification for mid-stretch block was recorded with the modified measurements and these were kept as the base for creation of specifications of different stretch brackets to ensure consistent fit. Table 7 shows the comparison of pressure reading of the new garments with the original.

| Mid-stretch block | Average Pressure Reading (kPa) |

||||

|---|---|---|---|---|---|

| Front waist | Back waist | Hip | Thigh | Knee | |

| Original | 109.4 | 64.25 | 52.54 | 33.53 | 28.17 |

| CLO Suggested POM | 24.21 | 37.38 | 27.18 | 20.76 | 18.49 |

| Final | 43.58 | 42.84 | 33.15 | 35.17 | 13.09 |

Table 7: Summary of the pressure readings of original and the two newly developed slim fit mid-stretch jeans.

Creation of high stretch and low stretch blocks

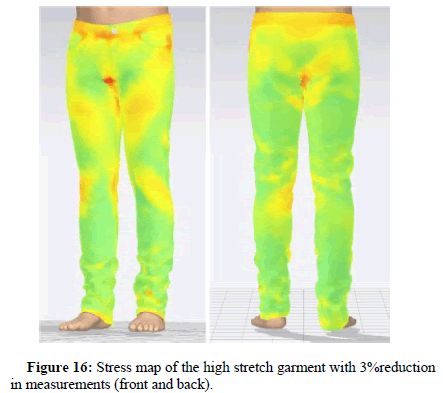

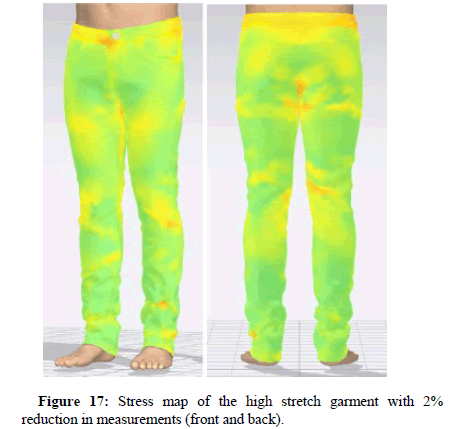

The literature suggests that reducing the girth measures by 2% or 3% when creating a pattern block for a stretch fabric with 30%-50% stretch can result in the best fit. To determine the optimal reduction percentage, two garments were made using CLO 3D with different reduction percentages, and their stress maps were analysed (Figures 16 and 17). The results were used to determine a standard reduction percentage for creating new garments with similar stretch percentages.

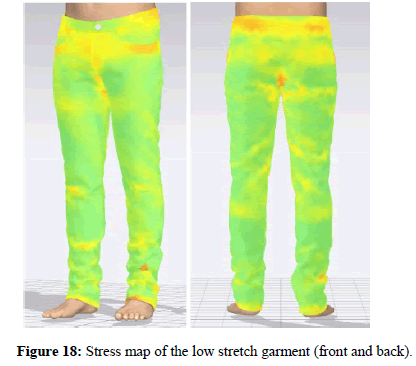

Analysing the pressure readings in Table 8 of both the reduction percentages states that the garment made from 3% reduction had certain areas that may feel tight/uncomfortable to the wearer since that pressure readings were beyond 50 kPa. Thus the standard reduction was set for 2%. Similarly for the creation of a low stretch block the girth measurement of the mid-stretch block was increased by 2% (Figure 18).

| High stretch block | Average Pressure Reading (kPa) | ||||

|---|---|---|---|---|---|

| Front waist | Back waist | Hip | Thigh | Knee | |

| 2% reduction | 44.71 | 46.98 | 38.38 | 38.82 | 35.17 |

| 3% reduction | 63.14 | 50.79 | 41.84 | 44.52 | 41.58 |

Table 8: Summary of the pressure reading of the high stretch slim fit jeans created by 2% and 3% reduction.

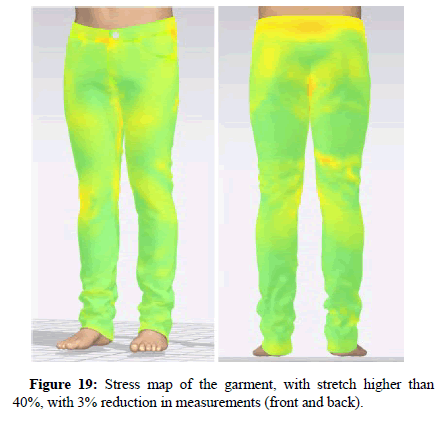

Considering the future potential of stretch denim, there are chances of introducing jeans with stretch percentage higher than 40%. Thus an additional standard was created using the same logic as that to create the high stretch garment.

Two outfits were created where the girth measures of the mid-block were lowered by 3% in the first outfit and 4% in the second. The stress maps of these garments were studied to determine the optimal reduction percentage for fabrics with higher stretch percentages. The findings shown in Table 9 suggested that a 3% reduction in the midstretch block can be used for fabrics with stretch percentages of above 40% (Figure 19). Table 10 shows the final pressure readings of the garments made from 4 stretch brackets.

| >40% Stretch Block | Average Pressure Reading (kPa) |

||||

|---|---|---|---|---|---|

| Front waist | Back waist | Hip | Thigh | Knee | |

| 3% reduction | 38.6 | 42.42 | 32.97 | 34.66 | 30.92 |

| 4% reduction | 47.25 | 53.05 | 45.08 | 41.52 | 35.92 |

Table 9: Summary of the pressure readings of slim fit jeans created with fabric stretch percentage above 40%.

| Stretch bracket | Average Pressure Reading (kPa) |

||||

|---|---|---|---|---|---|

| Front waist | Back waist | Hip | Thigh | Knee | |

| Low Stretch (0%-20%) | 43.29 | 50.28 | 40.1 | 31.46 | 22.4 |

| Mid-Stretch (20%-30%) | 43.58 | 42.84 | 33.2 | 35.17 | 13.1 |

| High Stretch (30%-40%) | 44.71 | 46.98 | 38.4 | 38.82 | 35.2 |

| >40% Stretch | 38.6 | 42.42 | 33 | 34.66 | 30.9 |

Table 10: Summary of the pressure readings of new slim fit jeans of all the stretch brackets.

Thus the final grid was created stating the reductions required on the specific point of measurements when creating specifications for different stretch percentages (Table 10).

Sample creation and wearer trial: The study conducted a blind wearer trial comparing the fit of garments made from the original specifications and the new specifications. Three wearers rated the fit of the garments using a questionnaire, and the feedback was compared and analysed (Table 11).

| Point of measurements | (0%-20%) A | (20%-30%) (Base) | (30%-40%) C | (>40%) D |

|---|---|---|---|---|

| Half waist circumference (Curved) | +2% of Base measurement | -2% of Base measurement | -3% of Base measurement | |

| Half hip | +2% of Base measurement | -2% of Base measurement | -3% of Base measurement | |

| Front rise | ||||

| Back rise | ||||

| Half thigh | +2% of Base measurement | -2% of Base measurement | -3% of Base measurement | |

| Half knee | +2% of Base measurement | -2% of Base measurement | -3% of Base measurement | |

| Half bottom opening | +2% of Base measurement | -2% of Base measurement | -3% of Base measurement |

Table 11: Standard reduction and increment grid for all the stretch brackets of stretch denim.

The results showed that the new specifications resulted in a better fit for low and mid-stretch jeans at the waist, crotch, and inner thigh regions. For high-stretch jeans, two out of three wearers found a better fit overall, but one found the hip area to be loose. However, the study was unable to conduct a wearer trial for fabrics with stretch percentages above 40% as the fabric could not be procured for sample creation.

Conclusion

The fit of a garment has a significant impact on customer buying behaviour as poorly fitting clothes can cause discomfort, dissatisfaction, and discourage future purchases. The study analyses the fit of stretch denim jeans with varying levels of stretch percentages creating a standard reduction method to ensure consistent fit across fabrics of different stretch percentages. Use of CLO 3D to analyse the current and future fits not only saves time and resources but also allows to make informed decisions about product design and fit which will ultimately lead to increased customer satisfaction and profitability. The future of research explores the combination of fit analysis with the manufacturing process and the composition of fabrics to provide higher quality garments, benefiting both consumers and the fashion industry.

Acknowledgements

The author would like to acknowledge the Sourcing Head of the Brand and National Institute of Fashion Technology, for extending their support in writing this research paper.

References

- Kim M, Lee H, Cho S (2015) A Study on the Effect of Fabric Properties on Stretch Performance of Men’s Jeans. Fash Text Res J 17(3):391-400

- Park JH, Kim Y, Seo Y (2015) Analysis of the influence of fabric properties on the fit and comfort of men's jeans. Fibres Polym 16(6):1412-1419

- Song G, Li S, Xiong B, Yang X (2016) Study on the mechanical and moisture absorption properties of stretch denim fabric. Fibers Polym 17(5):699-707

- Daşan Y, Babaarslan O (2020) Stretch and physical properties of weft stretch denim fabrics containing elastane and filament yarn. J Text Sci Fash Techno 4(4):1-10.

- Ozdil N (2008) Stretch and bagging properties of denim fabrics containing different rates of elastane. Fibres Text in Eastern Europe 16(1):66.

- Higgins K (2013) The evolution of denim washing. Int J Fash Des 6(2):107-114.

- Galliano D, Magrini MB, Tardy C, Triboulet P (2018) Eco-innovation in plant breeding: Insights from the sunflower industry. J Clean Prod 172:2225-2233.

- Sahu D, Pradhan B, Khasnobish A, Verma S, Kim D, et al. (2021) The Internet of Things in geriatric healthcare. J Healthc Eng.

- Nair S, Verma P (2017) Effect of different waistbands on the fit of jeans for Indian male. J Text Eng Fash Technol 3(3):1-6.

- Shah SK, Mangaraj S, Jariwala VR (2018) Study on body dimensions and its relation with jeans wear for Indian men. J Eng Technol 7(3):221-225.

- Singh A, Singh S (2015) A study on Indian male body types for garment design. J Text Cloth Sci 7(1):23-31.

- Kim S, Song G (2018) The effect of thigh circumference on the pattern design and fit of men's jeans. Fash Text 5(1):1-10.

- Rissanen E, Nurminen R (2015) An analysis of the development of men's jeans based on the theories of evolutionary psychology. Fash Style Pop 2(1):87-99.

- Kershaw G (2014) Patternmaking for menswear. Laurence King Publishing.

- Richardson K (2009) Designing and patternmaking for stretch fabrics. Bloomsbury Publishing.

- Shin KH, Kim YK (2019) Accuracy of CLO 3D in simulating the fit of a men's shirt. J Korean Soc Cloth Text 43(7):957-964.

- Wang J, Wu X, Zhang H, Peng W (2021) Accuracy evaluation of CLO 3D in simulating the fit of a wedding dress. Int J Cloth Sci 33(2):262-273.

- Zhang Y, Li Y, Luo J (2019) Evaluation of CLO 3D in simulating the fit of a women's dress. J Text Inst 110(3):359-369.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi

) Slim fit;

(

) Slim fit;

( ) Super slim fit.

) Super slim fit.

) Purchased

size down.

) Purchased

size down.

) Perfect

in same size; (

) Perfect

in same size; ( ) Perfect after size down.

) Perfect after size down.