Review Article, J Fashion Technol Textile Vol: 13 Issue: 1

Remedial Measures for Microfiber Mitigation in the Environment: A Review

Alisha Kakkar and Sudesh Kumar*

Department of Chemistry, Banasthali Vidyapith, Rajasthan, India

*Corresponding Author:Sudesh Kumar

Department of Chemistry, Banasthali Vidyapith, Rajasthan, India

E-mail: sudeshneyol@gmail.com

Received date: 10 November, 2023, Manuscript No. JFTTE-23-119859;

Editor assigned date: 13 November, 2023, PreQC No. JFTTE-23-119859 (PQ);

Reviewed date: 27 November, 2023, QC No. JFTTE-23-119859;

Revised date: 22 January, 2025, Manuscript No. JFTTE-23-119859 (R);

Published date: 29 January, 2025, DOI: 10.4172/2329-9568.1000381

Citation: Kakkar A, Kumar S (2025) Remedial Measures for Microfiber Mitigation in the Environment: A Review. J Fashion Technol Textile 14:1.

Abstract

The escalating usage of household laundry machines among city dwellers significantly contributes to the contamination of the environment due to fiber release. Microfibers and laundry discharge find their way into sewage systems adjacent to rivers and oceans, eventually resulting in marine pollution. Once emitted, these minuscule particles spread widely throughout the sea because of their low molecular mass. Raising public consciousness initiatives and enhanced training regarding nanofiber pollution during the laundering process will effectively raise social awareness about nanofiber release. This review delves into the mitigation strategies and techniques for the identification and characterization of microfibers.

Keywords: Microfibers; Pollution; Laundry; Techniques; Mitigation; Strategies; Artificial

Introduction

The clothing sector operates as a constantly shifting sector, given that the desires and demands of buyers frequently fluctuate. The rapidly evolving vogue and aesthetics requisites consistently seek innovative primary materials and recent items. This turns into a primary concern when contemplating eco-friendly material fabrication. Conversely, eco-friendliness revolves around the durability of a product and extending the material's lifespan to the utmost degree [1]. In the current era of speedy fashion prevailing in the textile industry, items are crafted for a briefer life span and limited utilization. The industry primarily prioritizes the quantity of products introduced in a season over the product’s excellence. During utilization, the unleash of nanofibers transpires while wearing, primarily during the laundering method. These fragments possess minuscule structures and are impervious to traditional filtration units. These nanofibers floating in aquatic environments are frequently mistaken for sustenance by diminutive organisms. From these microorganisms, there exists the potential for these nanofibers to be ingested by humans via the food web. The initial investigation into the release of nanofibers from fabrics was carried out by Browne and coauthors [2]. While examining nanoplastic particles in coastal waters worldwide, they discovered that nanofibers were the primary cause of nanoplastic pollution. Polymeric and synthetic fibers emerged as the primary nanofiber varieties contributing to nanoplastic pollution. Manmade fabric nanofibers are unleashed from the fabric during the manufacturing, utilization, and discard phases (Figure 1) [3]. While employing laundry detergents, scientists assessed the release of nano fabrics and stated the release of fabric ranging from 124 to 308 milligrams per kilogram of laundered textile and the associated tally signifies a range extending from 640,000 to 1,500,000 nanofibrils [4]. The latest studies by marine researchers from Flinders university shed light on the elevated nanofiber concentration in Naifaru, situated in the mid-Indian ocean. This area, which boasts an estimated population count of 5,408 exhibited microplastic levels ranging from 55 to 1127.5 nanoplastic particles per kilogram of deposition. This notably surpassed previously documented levels in densely populated areas in Tamil Nadu, which ranged from 3 to 611 microplastic particles per kilogram. Furthermore, particulate matter from deserted islands also disclosed a heightened proportion of microplastic particles, varying from 197 to 822 microplastics per kilogram [5]. Among various nanofiber pollution sources, domestic washing has emerged as the primary contributor due to inadequate rules and inappropriate polluted water management. Presently, limited research exists on measures to control nanofiber pollution.

Figure 1: Various phases for executing remediation approaches in microfiber shedding.

Literature Review

Identification and remediation techniques for microfiber pollution

Understanding the channels through which these contaminants propagate is crucial for effective treatment and resolution. Given the challenges associated with the entry and circulation of these minuscule contaminants from aquatic environments to humans, as well as their impact on human health, these are primary research areas that warrant investigation in the years ahead. Employing sustainable methodologies allows for the assessment and exploration of the harmful consequences of these contaminants, particularly in regions marked by extraordinary irregularities. The recurring presence of large amounts of artificial nanofiber particles poses a considerable challenge to control, and their quick dissemination disrupts worldwide ecological trophic stages. Various methods for identifying and characterizing man-made nanofibers and other harmful contaminants infiltrating the ocean are of paramount importance. Researchers are exploring cuttingedge visual, spectral, and molecular-scale technologies to effectively detect nanofibers. Both Raman and Fourier Transform Infrared (FTIR) spectroscopy have been employed for the rapid identification of nanofiber. In the latest investigation, microfibers were identified using FTIR in the stomach and intestines of fish specimens from examination of subtropical gyres. Alternative methods for identifying nanofibers in specimens of water involve the use of a specially designed net known as the Manta net, which gathers fibrils from the surface layer of the seas and rivers via a 30-mesh sieve [6]. Thorough structural examination and inspection of the surface characteristics of separate nanofibers can be conducted with a stereoscopic microscope and electron beam microscope. Addressing artificial microfiber release necessitates a concentration on the following: Rigorous governmental mandates, public awareness initiatives, and advancements in technology for effective elimination and mitigation.

Scientists are persistently exploring new microbes obtained from bacteria strains capable of breaking down specific polymer materials. However, it is equally crucial to determine how these enzymes can be deployed without adverse side effects. The bioaugmentation of nanofibers with microorganisms can demonstrate effectiveness only when ecological factors are conducive to bacterial proliferation and their functions. Microfiber marine contamination has presently become incredibly widespread, making manual removal a formidable task. The latest research merges optical techniques with more advanced structural and physiochemical analysis methods like Raman and FTIR spectral techniques. Raman and FTIR analysis methods assist in mitigating issues related to the misrecognition and undervaluation of nanofibers linked with primary recognition and verification through optical microscopy. In the scientific study conducted by Ding and co-authors to identify plastic materials in indigenous ocean fauna, plastics were examined and classified using electron beam microscopy [7]. These microplastics displayed diverse forms, comprising pieces, strands, particles, and sheets with sizes spanning from 57 to 8639 micrometers. Notably, plastic fiber materials measuring below 1 mm in length were prevalent and constituted the majority, comprising approximately 70% of the overall plastics found in various marine organisms. In the latest research, man-made microfibers within planktonic animal specimens from Charleston Harbor coastal convergence areas were identified and analyzed using fluorescence and visible-light microscopy. The observed microfibers ranged in diameter from approximately 43 to 104 micrometers [8]. FTIR analysis is an economical method employed to scrutinize the source and constitution of man-made textiles within a specimen. It provides insight into the precise atomic linkages present in the specimen, making the identification of polymeric materials quite straightforward. In the pursuit of detecting and analyzing artificial nanofibers within the digestive tracts of six industrially significant fish species from Central Chile, high-magnified FT-IR analysis and light microscopy were utilized. The nanofibers ranged in diameters from approximately 176 to 2842 mm and were predominantly detected as polyethylene, polyester, and polyethylene terephthalate [9].

Mitigation strategies

Manufacturing phase: Coating of synthetic fibers: Fibrous materials are identified as the primary origin of fiber release. Addressing this issue anticipatively involves changing or transforming these materials. Surface modification of fibrousmethod in fiber production, plays a crucial role in imparting both fashion and utility to materials. The surface modification methods can be done either chemically or mechanically. Surface modification by chemical method, especially, has a notable impact on minimizing fiber pollution [10-11]. In surface modification by chemical method, textile modifiers are evenly applied on the material surface using water as a solvent. Successive drying and setting methods eliminate the water, leaving a layer of textile modifiers on the fabric surface. This coating is believed to affix the textiles and avoid their sliding and separation.

e Falco and co-authors undertook an initiative to minimize fiber release from the surface of polyamide by employing a biopolymer i.e., pectin [12]. To facilitate the efficient use of pectin on polyamide, researchers altered the pectin structure with glycidyl methacrylate. Subsequently, the pectin-methacrylate composite was incorporated onto the polyamide surface. The primary objective behind the structure of pectin alteration was to minimize pectin’s hydrophilicity which is a crucial aspect in fabric processing. These modifications efficiently contributed to minimizing the microfiber release from the fabric. To sum up, when opting for treatments to minimize fiber release, it's essential to consider the sustainability of the selected coating, the compatibility of the finishing agent with the fabric, the specific operating conditions (Table 1), and the preservation or enhancement of the textile’s favorable characteristics. While many studies have focused on parameters such as the kind of washing machine employed and fabric deterioration on the microfiber release, more research is needed on different parameters such as textile kind, textile manufacturing, and coating methods to draw exact findings. Liu et al. recommended further investigation to gain insights into the characteristics, origins, and impacts of nanofibers in the ecosystem, and also underscored the significance of nanofibers on the long-term viability of the fabric and clothing industry as the primary domain necessitating additional comprehensive research [13]. The advancement and adoption of environmentally conscious bio textiles and renewable biomaterials, along with the utilization of naturally sourced and renewed textile resources, represent the primary avenues to address nanofiber release in the emerging trends of the apparel and clothing sectors. The structural characteristics of thread and textile including the ratio of various fibrous materials, the number of fibers per meter length, size of the fiber, thread rotation, fiber compactness, yarn thickness, weave pattern repetition, and mass of fiber/m2 will impact the fiber’s inhibition to balling and wear. The strategy for managing materials and effluents must integrate sustainable guidelines and provide initiatives for upcycling, dismantling, and the development of long-lasting patterns in certain emerging nations that serve as the primary hubs for fabric and apparel production and export.

| Kind of laundry machine | Temperature | Time | Frequency of wash cycles | Washing liquid | Conditioner |

|---|---|---|---|---|---|

| - | With temperature rise, microfiber shedding rises | - | Minimization in fiber release in initial 4 wash cycles | Fiber release rises with the use of organic wash liquid | No influence of softener/conditioner |

| Upper-loading washing machines result in more fiber release than face-loading washers | - | - | - | - | - |

| Drying causes 3.5 times more fiber release than washing | - | - | Lowering in fiber shedding in following wash cycles | No influence | No influence |

| - | - | No influence | - | Rise in microfiber release with the use of washing liquid | - |

| Lab washing machine results in smaller fiber release than household washing machine | A rise in temperature increases fiber release | - | - | Increase microfiber release | - |

| - | - | - | Microfiber release lowers in 1 to 5 wash | - | - |

| - | - | - | Microfiber release lowers in the following wash cycles | - | - |

Table 1: Influence of different washing conditions on fiber release.

Enhancing decomposability of textile materials: The decomposability of fabrics plays a crucial role in identifying the extent of their negative impact on the surroundings. Enhancing the biodegradable ability of fabrics can reduce their persistence in the surroundings. It has been observed that the virgin fabrics’ rapid breakdown lessens their environmental influence, making fiber release less concerning in textiles crafted from organic fiber materials. This broadens the strategy for eliminating fiber release to changing the decomposability of fabrics [14]. It's important to note that the decomposability of natural fabrics can be modified during processing methods such as cloth dyeing and surface treatment. The research conducted by Lykaki and co-authors highlighted that the degradability of viscose fibers can be hindered by the application of industrial antibacterial coating (RUCO-BAC HAS CONC) in comparison to untreated samples. The bonding between antibacterial coating and viscose fiber hampers the interplay between microorganisms and viscose, leading to decreased biodegradation [15]. Other research endeavors have also noted alterations in the decomposability of cotton in the starting levels during various finishing agents like silicone conditioner, wrinkle-free treatment, hydrophobic, and a fiber-reactive colorant [16]. Therefore, when proposing fabric finishing to meet operational properties, it's essential to balance and consider decomposability. In situations involving man-made fabrics, which are inherently non-decomposable, there exists the opportunity to enhance biodegradability. Consequently, enhancing the decomposability of artificial fabrics stands as a promising method to mitigate the environmental effects of fibers. The degradability rate of artificial fabrics can be modified by altering the fabric during the extrusion process while preserving the fabric’s favorable characteristics. However, these alterations should not have adverse effects, and caution must be exercised in this regard. Additionally, enhancing the degradability of fabrics only delays their persistence, without mitigating their overall environmental impact. Fabrics with enhanced decomposability can still act as carriers of pollutants over their lifespan. Similar to virgin and reprocessed fabrics that emit adhered contaminants into the surroundings, these fabrics also contribute to environmental pollution. This approach may minimize the duration of the effect from man-made fabrics, but it represents only a tiny effort in decreasing their overall ecological footprint [17].

Results and Discussion

Utilization phase

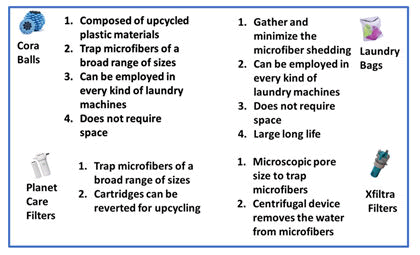

Employment of laundry aids: The employment of laundry agents, primarily detergents, adversely affects microfiber pollution as it expedites the release of fibers from the material surface [18]. Conversely, fabric softeners frequently employed laundry agents to maintain textile softness and reduce wrinkles have shown a favorable impact in regulating fiber release during laundering [19]. Researchers recommend incorporating conditioners at the time of the washing process instead of post-washing. Both the processes of conditioner application (during and post-laundering) contribute to fabric smoothness and desired texture. However, integrating softeners in the washing process notably enhances the minimization of fiber release. The critical factor to consider with the utilization of conditioners is their chemical constituents, which are non-decomposable and consequently, influence the surroundings. The promotion of ecofriendly softening agents should be encouraged, and their efficiency in reducing fiber release should be assessed when contemplating their use as a viable method. Specifically innovative products in this area constitute Microfiber-catching bags, Cora balls, LUV-R filter systems, eco-friendly filtration systems, and several others. These innovative products effectively capture fibers released from artificial fabrics, which can further be recovered from them. These innovative products can be categorized into two main groups: Internal tools and outer filtration systems. Internal tools are utilized inside the laundry machine, whereas outer filtration systems are affixed to the drain pipe of the laundry devices. Wash bags and Cora balls are examples of internal tools that have proven to be efficient in managing fiber release. Research endeavors examined the effectiveness of Cora balls when laundering different man-made fabrics such as acrylic, polyester, and poly-cotton fabrics. The results demonstrated a 31 ± 8% decrease in fiber presence in the wastewater [20]. Another intriguing aspect of Cora balls is their ability to curtail fiber shedding from the surface of textiles when laundering, in addition to trapping released threads. However, some drawbacks are associated with these balls. Post-use, the threads entrapped in the balls need elimination, and the balls must be rinsed before the subsequent wash cycle, which can be cumbersome due to threads becoming entwined in the ball’s elastic framework. Secondly, the washing bag, serving as an internal laundry product, operates differently from Cora balls in terms of usage. With Cora balls, they are just placed inside the washing machine drum, whereas when employing washing bags, fabrics are first placed within the bags and then placed inside the laundry drum. Consequently, fibers released from the artificial textiles are captured at the edge of the laundry bags, avoiding their release into the laundry discharge.

Washing bags and fourth element laundry bags are distinct washing carriers crafted from nylon fibers and equipped with zip locks. These bags feature small pores measuring 50 μm in size. The nylon fibers utilized in the laundry bags were kept natural and uncolored, ensuring their freedom from any additional supplements. Despite the micropore diameter being 50 μm, these washing bags effectively capture threads thinner than 10 μm. These washing bags are recommended for utilize till a temperature of 40°C and are thus not appropriate for washes with temperatures exceeding 40°C. Additionally, since these washing bags are crafted from artificial nylon fibers, they are prone to microfiber pollution. Moving on, another significant group of laundry additives comprises filter systems (Table 2). These washing filters are typically affixed to drain pipes, capable of sieving threads from the wastewater and discharging contaminants with some threads into drainage networks. Various washing filters designed to trap fibers have been commercialized, such as LUV-R filter systems, XFiltra™, Filtrol 160™, and PlanetCare filter systems. The fundamental idea behind these laundry filter systems are straightforward: The wastewater discharge is directed through these washing filters, which aim to trap and hold fibers, ultimately leading to some or no fibers being discharged into the surroundings. PlanetCare Filters represent a type of outer filtration system, demonstrating a notable efficiency of 25% of fibers in the wastewater, as documented in the study by Napper and co-authors [21]. These filter systems have been documented to trap threads spanning from 50 μm to 5 mm in length. Notably, these cartridges can be sent back to the producers after 20 wash cycles. The producers are responsible for washing the cartridges, and ensuring they are ready for subsequent use. This process guarantees the proper removal of microfibers accumulated in the filter systems. The girlfriend collective is another filtration system composed of a metal grid with a pore diameter of 200 μm. According to the producer, these filter systems can trap fibers as tiny as 0.072 mm. Studies suggest that a collective approach, utilizing both internal drum aids and outer filtration systems can enhance microfiber shedding efficacy.

| Fabric type | Laundry device | Washing parameters | Filtration system | Quantification |

| Pure polyamide 6.6 Pure acrylic Poly polyester Polyester-cotton blend (65/35 %) |

Linitest device | UNI EN ISO 105-C12 for commercial laundering and UNI EN ISO 105-C06 for household laundering | Fluoropolymer filtration of pore diameters 0.1 μm, 0.2 μm, 5 μm | Calculating |

| Pure polyacrylic Pure polyamide Pure polyester fur jacket |

Whirlpool laundry machine | Time: 75 min, Rotation: 1400 rpm | Microporous nylon filter of pore diameter 25 μm | Measuring |

| Polyester fur jacket |

Laundry machines (both load) | Upper load configuration: Temp-29.6°C, Time: 30 min, face load configuration: Temp: 29 to 41°C, Time: 24 min, Speed: 1200 rpm, No utilization of wash liquids | Nylon filament filtration system (333 μm and 20 μm) | Measuring |

| Puff blankets | Laundry machine(front-facing) | Time: 15 min, Temp: 30°C, Rotation: 600 rpm, wash liquids and conditioners employed | Steel filtration unit (200 μm × 200 μm) | Measuring |

Table 2: Different filters employed in laundry devices.

Discard phase

Wastewater management facilities: Wastewater purification strategies serve as a broad-level method to eliminate the shedding of fibers from household washing discharge. The primary goal of these polluted water management facilities is to eliminate potential contaminants from water before it is discharged into the surroundings. Depending on their specific use, these polluted water treatment facilities can be categorized as wastewater treatment facilities, household discharge treatment facilities, and clean water purification facilities. Modifying household discharge treatment facilities can effectively lower the dispersion of fibers from household washing into the surroundings. Similarly, the adaptation of polluted water treatment facilities in the fabric manufacturing sector can help regulate the shedding of fibers occurring during the production of apparel. These management facilities are efficient in trapping tiny plastics, achieving a removal rate of up to 98%. However, due to the vast amount of polluted water processed, a substantial number of plastics still manage to enter the surroundings, especially through wastewater [22,23]. Scientists have meticulously examined various segments of sewage treatment facilities and interfered specifically in the part before the drainage pipe, precisely between the purification phase and the ultimate disposal. Comprehensive evaluations encompassing the component selection, production method, product evaluation, price considerations, and comprehensive examination within renewable and stable structures should be conducted. The sewage treatment facility holds promise in terms of trapping fibers. A primary challenge faced by these facilities revolves around the substantial amount of wastewater being processed, leading to a considerable release of fibers into the surroundings. Additionally, the subsequent impacts of these treatment facilities raise significant concerns. Zhang and co-authors have documented that treatment plant residue could introduce 4,010,000 kg per year of plastic particles into land habitats in the United States [24]. Additionally, Petroody and co-authors asserted the presence of 129 to 238 plastics per gm of residue from sewage treatment plant facilities [25]. Furthermore, these treatment plant residues are frequently employed as fertilizing agents, transporting these plastic particles to farmlands. Therefore, it is imperative to devise comprehensive strategies for wastewater effluent management to enhance the effectiveness of sewage treatment facilities (Figure 2).

Figure 2: Advantages of different washing products.

Conclusion

This review provided valuable knowledge about potential methods for addressing fiber release. These solutions span different stages and levels of the process. In the manufacturing phase, alterations to fabrics have been proposed. These changes can either minimize microfiber release or enhance the degradability of man-made textiles. During the utilization stage, specifically during garment washing, the use of laundry aids has been observed to potentially minimize microfiber shedding. It emphasized the importance of public consciousness and government initiatives, as these are vital. Government entities should enhance the integration of sellers, wastewater purification facilities, and laundry machine producers to take a leading role in addressing the issue of fiber release. During the discard phase, wastewater purification strategies are explored. This comprehensive overview provides in-depth knowledge of the continuing research efforts aimed at tackling microfiber pollution.

Acknowledgment

This article would not have been possible without the unwavering assistance of my supervisor Dr. Sudesh Kumar. His passion, experience, and meticulous attention to detail have been an inspiration and have helped me stay on track with my work.

Conflict of Interest

Neither a technological nor a fiscal conflict of interest exists.

Research Funding

No research funding is available.

References

- Rathinamoorthy R, Raja Balasaraswathi S (2021) A review of the current status of microfiber pollution research in textiles. Int J Cloth Sci Tech 33: 364-387.

- Browne MA, Crump P, Niven SJ, Teuten E, Tonkin A, et al. (2011) Accumulation of microplastic on shorelines worldwide: Sources and sinks. Environ Sci Technol 45: 9175-9179.

[Crossref] [Google Scholar] [PubMed]

- Belzagui F, Crespi M, Alvarez A, Gutierrez-Bouzan C, Vilaseca M (2019) Microplastics' emissions: Microfibers’ detachment from textile garments. Environ Pollut 248: 1028-1035.

[Crossref] [Google Scholar] [PubMed]

- de Falco F, di Pace E, Cocca M, Avella M (2019) The contribution of washing processes of synthetic clothes to microplastic pollution. Sci Rep 9: 6633.

[Crossref] [Google Scholar] [PubMed]

- Patti TB, Fobert EK, Reeves SE, da Silva KB (2020) Spatial distribution of microplastics around an inhabited coral island in the Maldives, Indian Ocean. Sci Total Environ 748: 141263.

[Crossref] [Google Scholar] [PubMed]

- Masura J, Baker J, Foster G, Arthur C (2015) Laboratory methods for the analysis of microplastics in the marine environment: Recommendations for quantifying synthetic particles in waters and sediments.

- Pozo K, Gomez V, Torres M, Vera L, Nunez D, et al. (2019) Presence and characterization of microplastics in fish of commercial importance from the Biobio region in central Chile. Mar Pollut Bull 140: 315-319.

[Crossref] [Google Scholar] [PubMed]

- Tiwari M, Rathod TD, Ajmal PY, Bhangare RC, Sahu SK (2019) Distribution and characterization of microplastics in beach sand from three different Indian coastal environments. Mar Pollut Bull 140: 262-273.

[Crossref] [Google Scholar] [PubMed]

- Ding J, Li J, Sun C, Jiang F, Ju P, et al. (2019) Detection of microplastics in local marine organisms using a multi-technology system. Anal Methods 11: 78-87.

- Kang H, Park S, Lee B, Ahn J, Kim S (2021) Impact of chitosan pretreatment to reduce microfibers released from synthetic garments during laundering. Water 13: 2480.

- de Falco F, Cocca M, Guarino V, Gentile G, Ambrogi V, et al. (2019) Novel finishing treatments of polyamide fabrics by electrofluidodynamic process to reduce microplastic release during washings. Polym Degrad Stab 165: 110-116.

- de Falco F, Gentile G, Avolio R, Errico ME, di Pace E, et al. (2018) Pectin based finishing to mitigate the impact of microplastics released by polyamide fabrics. Carbohydr Polym 198: 175-180.

[Crossref] [Google Scholar] [PubMed]

- Liu J, Yang Y, Ding J, Zhu B, Gao W (2019) Microfibers: A preliminary discussion on their definition and sources. Environ Sci Pollut Res Int 26: 29497-29501.

[Crossref] [Google Scholar] [PubMed]

- Zambrano MC, Pawlak JJ, Daystar J, Ankeny M, Cheng JJ, et al. (2019) Microfibers generated from the laundering of cotton, rayon and polyester based fabrics and their aquatic biodegradation. Mar Pollut Bull 142: 394-407.

[Crossref] [Google Scholar] [PubMed]

- Lykaki M, Zhang YQ, Markiewicz M, Brandt S, Kolbe S, et al. (2021) The influence of textile finishing agents on the biodegradability of shed fibres. Green Chem 23: 5212-5221.

- Zambrano MC, Pawlak JJ, Daystar J, Ankeny M, Venditti RA (2021) Impact of dyes and finishes on the microfibers released on the laundering of cotton knitted fabrics. Environ Pollut 272: 115998.

[Crossref] [Google Scholar] [PubMed]

- Ladewig SM, Bao S, Chow AT (2015) Natural fibers: A missing link to chemical pollution dispersion in aquatic environments. Environ Sci Technol 49: 12609-12610.

[Crossref] [Google Scholar] [PubMed]

- Rathinamoorthy R, Balasaraswathi SR (2022) Investigations on the impact of handwash and laundry softener on microfiber shedding from polyester textiles. J Text Inst 113: 1428-1437.

- Agarwal G, Koehl L, Perwuelz A, Lee KS (2011) Interaction of textile parameters, wash-ageing and fabric softener with mechanical properties of knitted fabrics and correlation with textile-hand. I. Interaction of textile parameters with laundry process. Fiber Polym 12: 670-678.

- McIlwraith HK, Lin J, Erdle LM, Mallos N, Diamond ML, et al. (2019) Capturing microfibers–marketed technologies reduce microfiber emissions from washing machines. Mar Pollut Bull 139: 40-45.

[Crossref] [Google Scholar] [PubMed]

- Napper IE, Barrett AC, Thompson RC (2020) The efficiency of devices intended to reduce microfibre release during clothes washing. Sci Total Environ 738: 140412.

[Crossref] [Google Scholar] [PubMed]

- Murphy F, Ewins C, Carbonnier F, Quinn B (2016) Wastewater treatment works (WwTW) as a source of microplastics in the aquatic environment. Environ Sci Technol 50: 5800-5808.

[Crossref] [Google Scholar] [PubMed]

- Xu X, Hou Q, Xue Y, Jian Y, Wang L (2018) Pollution characteristics and fate of microfibers in the wastewater from textile dyeing wastewater treatment plant. Water Sci Technol 78: 2046-2054.

[Crossref] [Google Scholar] [PubMed]

- Zhang J, Wang L, Kannan K (2019) Polyethylene terephthalate and polycarbonate microplastics in pet food and feces from the United States. Environ Sci Technol 53: 12035-12042.

[Crossref] [Google Scholar] [PubMed]

- Petroody SSA, Hashemi SH, Gestel CA (2021) Transport and accumulation of microplastics through wastewater treatment sludge processes. Chemosphere 278: 130471.

[Crossref] [Google Scholar] [PubMed]

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi