Review Article, J Fashion Technol Textile Eng Vol: 5 Issue: 4

Research on the Improvement on the Performance of Thermal Underwear Based on the Demands of Chinese Consumers

Bing Xu* and Jianhui Chen

Department of Fashion and Art Design, School of Fashion and Art Design, Donghua University, Shanghai, China

*Corresponding Author : Bing Xu, Phd

School of Fashion and Art Design, Donghua University, Shanghai, West Yanan Road 1882, Changning District, Shanghai, China, Postcode: 200051

Tel: +86 18302185936

E-mail: susiebing@126.com

Received: September 28, 2017 Accepted: November 01, 2017 Published: November 05, 2017

Citation: Xu B, Chen J (2017) Research on the Improvement on the Performance of Thermal Underwear Based on the Demands of Chinese Consumers. J Fashion Technol Textile Eng 5:4. doi:10.4172/2329-9568.1000161

Abstract

Thermal underwear has won a large proportion of Chinese clothing market over the last few decades. However, most of the current products in thermal underwear market can hardly meet consumers’ demands because it still exist some disadvantages, such as poor fabric performance and unpopular styles. To fully understand the weaknesses in the performance of current thermal underwear, this paper is aimed at intensively investigating consumers’ demands from the aspects of garment selecting standards, garment fabrics, and garment structures. Based on related literature, crucial survey factors were selected in relation to fabric comfort and garment structure. The price factor was also considered in the research. The survey, using questionnaires as the tool, was mainly conducted in China. It turned out that there was blindness in consumers’ process of purchasing thermal underwear. Meanwhile, we have concluded main defects in the long-term using process of thermal underwear and a list of consumers’ expectations. Then, suggestions were given to provide manufacturers with guidelines to improve their strategies. Besides, two new product development schemes were proposed with new design of fabric structure and component, garment style sketches, and garment structure patterns.

Keywords: Thermal underwear; Fabric comfort; Garment structure; Clothing performance; Consumer demand

Introduction

Clothing, which plays a significant role in human’s life, protects human body from the unpredictable external environment, and keeps body in a comfortable subenvironment. Among various kinds of clothes, underwear is taken as one of the most important garments for human beings, which can maintain human body’s temperature in a relatively constant level effectively and directly. Therefore, many researchers have focused their researches on the development technology of underwear.

Review of Relative Literature

Many researches can be found on clothing thermal comfort from the aspects of outside temperature, human condition, textile materials, etc. Fukazawa et al. [1] utilized sweating thermal manikin to study the influence of heat and water vapour transfer on clothing thermal comfort. Li et al. [2] studied the physical parameters change rule of human body in protective clothing in high temperature and high humidity environment. Nuñez et al. [3] discussed the usability of thermal comfort and the function of clothing for protecting human body from the extreme temperature. Gavhed et al. [4] examined the influence of different exercise intensity, temperature, and clothing materials on thermal responses in human in winter clothing. Ueda et al. [5] designed a survey to examine the differences of thermoregulatory function on the clothing microclimate temperature among people in different ages, inorder to improve clothing’s thermal comfort. Lu et al. [6] studied the effect on regional thermal resistance by wind and walking, and stated that walking speed has small effect on clothing’s thermal resistance. Lee et al. [7] discussed the thermal effects of different types of garments on the body temperature of men in 10°C. Lizak et al. [8] studied the effect of different material structures on clothing textiles’ performance such as thermal conductivity and heat transfer. Huang et al. [9] provided a serial method for predicting local thermal sensation in the segmented thermal model. Mao et al. [10] introduced a simulation-based and lifestyle-oriented CAD system for designers of thermal quality clothing.

Although plenty of researches have conducted on the improvement of the thermal comfort of clothing, little research can be found on the performance of thermal underwear, especially on the performance improvement based on consumer demand. Actually, consumer plays a significant role on product promotion. Therefore, this paper aims at providing a detailed research on the improvement of thermal underwear’s performance based on consumer demand, as well as putting forward the corresponding products designing schemes.

The Performance of Thermal Underwear

The performance of thermal underwear includes fabric performance and garment structure performance. Fabric performance mainly includes fabric comfort (moisture absorptivity, permeability, heat retaining ability, softness, antistatic property, etc.), durability (strength, wear-resisting condition, heatproof condition, sun-proof condition, etc.), physical quality property (shape stability, crease resistance, pilling resistance, etc.), and maintainability [11-13].

Garment structure performance mainly includes structure comfort and structure aesthetics. Structure comfort means that good garment structure provides wearing comfort and body moving comfort; structure aesthetics means that an outstanding garment structure contributes to the improvement of people’s overall appearance [14,15].

Therefore, the design and development of thermal underwear need to concentrate mainly on two aspects, i.e., fabric with high technology and garment structure with comfort and aesthetics.

The Current Situation of Thermal Underwear

Thermal underwear has broad markets in China. The sales volume of thermal underwear per year in China is over two hundred million pieces. While each year there are dozens of new brands entering this market, which brings fierce competition to the old and new manufacturers. Now the number of thermal underwear manufacturers has increased from dozens to hundreds. Most of traditional thermal underwear is heavy and loose, which influences its appearance. With the improvement of people's living standard and transformation of their life conception, an increasing number of consumers are expecting to wear slim and light thermal underwear in winter. In order to win more consumers, different manufacturers have taken different actions, such as developing new hi-tech thermal fabrics and creating new garment styles [13]. At present, the features of thermal underwear in the market are as follows:

Fabric features

The fabric structures of thermal underwear in the present market can be roughly divided into three categories: a. the three-tier type fabric. It consists of surface layer, inner layer and sandwich layer (flocculus), and the sandwich layer mainly contributes to the heat preservation effect; b. the composite fabric. The structure of the composite fabric is similar to the first type, except that its core layer is made from a bundle of fluffy fibers; c. raising type fabric. It has both top layer and raising layer [16].

The surface jacquard of the thermal underwear’s fabric is usually made from cotton, polyester, acrylic, nylon, spandex, viscose fiber, etc. Other parts of the fabric always use cotton, wool, polyester, polypropylene, spandex, etc. The sandwich layer often uses ultrafine polyester, hollow pet staple fiber, or other materials with good heat preservation performance. Cashmere and camel hair can also be found in some high-class fabrics. With the development of new fibers, bamboo fibers, lycra, modal, milk protein fibers or other new materials are added into the fabric production, which increases the performance of the garment [17].

However, some fabrics of thermal underwear have the problems of heavy, thick, small elasticity, and poor permeability. Moreover, most of the consumers do not have the sufficient knowledge and scientific approaches for thermal underwear purchasing. Also, many manufacturers are lacking in understanding of their target consumers. Therefore, products in the present market always cause consumers’ dissatisfaction.

Structure features

Most of the thermal underwear in the market is monotonous and loose by simple structure design, simple cutting and sewing, which makes the wearers look puffy and cumbersome. Although some of the manufacturers have taken actions to improve its performance, such as using elastic fibers for styling, changing the shape of collars and lower hems, multicolor splicing, and printing decorations on the surface fabrics, etc., it still cannot meet consumers’ demands completely [18,19].

For fully meeting consumers’ demands and developing high quality products, this paper aims to intensively investigate consumers’ requirements on thermal underwear and provide the corresponding suggestions and solutions to manufacturers.

Research Methods

The investigation indicators of the research

There are many factors influencing the performance of thermal underwear. This research mainly focuses on the fabric comfort and garment structures to investigate consumers’ demands.

The indicators of fabric comfort

Heat retention: The property of heat retention of fabrics is the primary performance for thermal underwear. Factors mainly affecting fabric heat retention effects are materials’ thermal conductivity and fabrics air content. The thermal conductivity of materials is assessed by the coefficient of thermal conductivity λ(unit: Wï¼Â(m°C)), the smaller the λ is, the better the heat retention is. The common materials for thermal underwear are cotton (λ= 0.071~0.073), wool (λ =0.052~0.055), viscose fiber (λ= 0.055~0.07l), terylene (λ=0.084), polypropylene fiber (λ=0.221~0.302) and so on. Still air has the smallest coefficient of thermal conductivity (λ=0.027), therefore, fibers are usually made into hollow structure, porous structure, or three-dimensional structure to increase their still air content to reduce the λ [17]. The higher the fabrics’ air content is, the better the heat retention is. Hence, fabrics for thermal underwear often use firmly milled wool, camel hair, as well as bulked fibers and polyester wedding in the sandwich layer, for increasing the air content to achieve a better heat retention.

Air permeability: Air permeability of fabrics is one of the most important indicators for wearing comfort of thermal underwear. The main factors influencing fabrics’ air permeability are fabric density, fabric thickness and their materials [20]. Fabrics with loose structure have less resistance to the airflow, which means they have better air permeability. Cotton fabrics have good permeability, and wool fabrics are loose with low density. Also, as wool fibers have scales on the surface which are not proper for the inner fabric, therefore, cotton and wool are usually used as the main materials in the surface fabric of thermal underwear. In new technical area, the permeability of bamboo fibers is 3.5 times as much as that of cotton fibers, so bamboo fibers are very suitable for the inner fabric [21].

Hygroscopicity: Clothing fabrics’ hygroscopicity influences the humidity within human’s clothing subenvironment. High humidity can cause body discomfort. Factors mainly affecting fabrics’ hygroscopicity are materials’ commercial moisture regains and fabric structures. The higher the commercial moisture regain is, the better the fabric’s hygroscopicity is, which means the fabric with high commercial moisture regain is easier to absorb sweat from the body. The common materials used in thermal underwear and their commercial moisture regain (in brackets) are cotton (8.5%), wool (15%), viscose (13%), polypropylene fiber (0%), etc. It can be seen that natural fibers and artificial fibers have high hygroscopicity, compared with synthetic fibers. Bamboo fibers, because of the innumerable oval holes on their section, can absorb and evaporate vapor instantly, so they are excellent fabric materials for thermal underwear [22-24].

Elasticity: The elasticity of the fabric is mainly determined by the elasticity of the fiber, which is evaluated by the fiber’s elastic recovery rate. The higher the elastic recovery rate is, the better the fiber’s elasticity is, and vice versa. The common elastic materials used in thermal underwear are wool, polyester, polypropylene, spandex, etc. In terms of new type fibers, bamboo fiber, lycra, and PTT fiber are proved to have great elasticity [25]. Fabric elasticity is not only related to the wearing comfort and garment beauty, but also influences the garment durability. The better the fiber’s elasticity is, the better the fabric’s durability is.

Weight: The weight of the fabric affects the thickness of the garment, which is determined by the material’s density and structure. Fibers with the low density provide larger coverage with lower weight. Therefore, they are the ideal materials for light clothing [26]. Because of the low density, wool, polyester, polypropylene, and PTT fibers are usually taken as materials for light thermal underwear. The sandwich layer of the fabric always chooses camel hair, ultrafine fibers, hollow fibers, and cotton blended materials to decrease the fabric density per volume.

The indicators of garment structure comfort

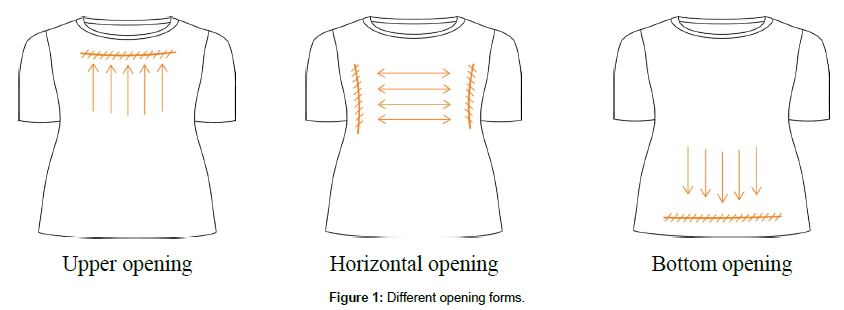

The clothing opening form: The opening form of thermal underwear is crucial to its heat retention performance. The opening forms can be divided into upper opening, horizontal opening, and bottom opening (shown in Figure 1). The clothing with both upper and bottom openings has obvious cooling effect, which is because of the airflow stack effect by promoting human’s clothing internal air convection [27]. With fewer openings, there will be less convection within the clothing subenvironment, which allows the still air to keep warm in the garment. Hence, using fewer openings helps to improve the performance of thermal underwear.

The level of tightness: The level of thermal underwear’s tightness affects the garment’s appearance, wearing comfort and thermal effect. Garments which are too loose influence the aesthetic and generate flowing air, however, garments which are too tight cause body discomfort and loss of still air. Moderate loose quantity between human body and garment can not only keep enough still air for thermal effect but also provide wearing comfort. According to the calculation of optimum thickness of air, the optimal value of the loose quantity is 0.6~1.3 cm [16].

The length: The garment length influences the heat retention and the appearance of thermal underwear. When taking the structure performance into consideration, the longer the garment is, the better the thermal effect is; however, when considering from the aesthetic aspect, clothing should be designed at a proper length.

Research design

By reviewing a large number of literature and related information, this research selected several crucial factors on the performance of thermal underwear, aiming at understanding consumers’ demands on thermal underwear from the aspects of practicality and production aesthetics. Questionnaire is taken as the main research tool.

The questionnaire mainly consists of four parts:

A. The basic information of respondents including gender, age and residence;

B. Consumers’ shopping behaviors, including consumers’ shopping habits for thermal underwear and their selectioning styles;

C. Problems existing after a long-term wearing, including decrease of heat preservation effect, decrease of elasticity, poor permeability, etc.;

D. The expectation for the performance of thermal underwear from consumers, including the fabric performance (heat retention, permeability, elasticity, etc.) and design features (length, collar shape, cuff, lower hem, etc.). For fully understanding the demands, product price factor was added into the research.

Sampling

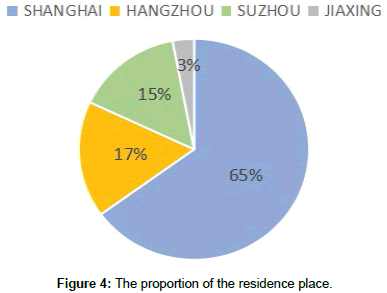

600 structured questionnaires were distributed to consumers mainly in Shanghai, China, as well as several places nearby, i.e., Hangzhou, Suzhou, and Jiaxing. The respondents were anonymous and a brief written explanation was given to instruct how to conduct the survey. The research was conducted from March 2017 to May 2017, totally three months. After eliminating incomplete questionnaires, 480 out of 600 were kept for further analysis; the overall response rate was 80%.

Results

The collected data were processed by SPSS 17.0 and Excel. The results were shown by figures and tables, which contributed to intuitive understanding of consumers’ demands.

The basic information of respondents

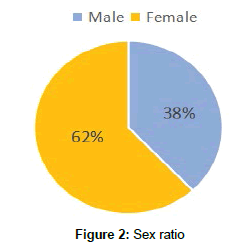

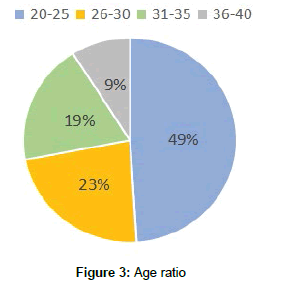

It is shown in Figure 2 that female respondents in this research were more than male respondents, which accounted for 62% and 38% respectively. The survey was conducted among consumers over 20 years old. Figure 3 indicates that respondents were mainly around 20-35 years old (accounted for 91%), and from Figure 4 it can be seen that a large proportion of respondents were residents in Shanghai (accounted for 65%), as well as consumers from other parts of China.

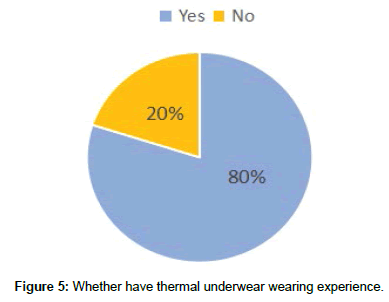

The analysis of consumers’ shopping behaviors

From Figure 5 it can be seen that there were 80% of the respondents having the experience of wearing thermal underwear, which meant that thermal underwear had been very common in people’s lives. With the improvement of human’s living standard, the demands from many aspects on the garment are increasing.

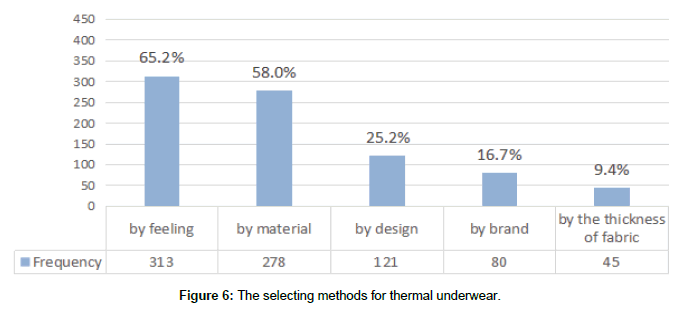

When it comes to the selection styles, over 65% respondents stated that most of the time they chose thermal underwear mainly by feel, and 58% respondents chose the option that ‘according to the materials listed on the tag, such as cotton, wool, terylene, etc.’ Answers in this section were supported by multiple-choice. Meanwhile, ‘by design’ and ‘by brand’ were chosen by a few respondents. The results are shown in Figure 6.

It can be concluded from the section that most of the consumers had no scientific methods for purchasing thermal underwear. In other words, there was blindness in consumers’ buying process for thermal underwear. On the other hand, the result reminds us of the importance of consumers’ comprehensive feelings brought by the garment, such as hand feelings and material properties.

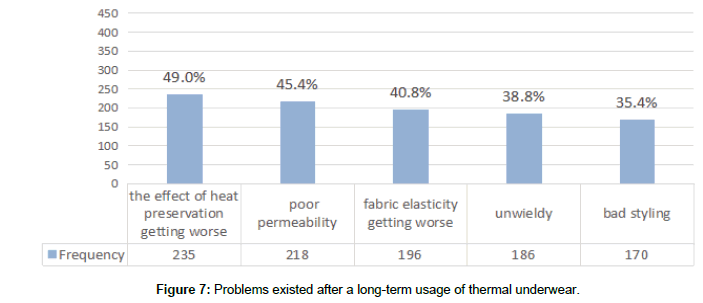

Problems existed after a long-term usage

Understanding the problems in products’ use-phase is the foundation of making targeted improvements in the product performance. Figure 7 states that the main problems during a long-term wearing of thermal underwear were ‘the effect of heat preservation is getting worse’ and ‘poor permeability’. The two options were selected by a large percentage of consumers, which accounted for 49% and 45.4% respectively. In addition to the above mentioned problems, ‘fabric elasticity is getting worse’, ‘clothing is unwieldy’ and ‘bad styling’ were also voted by a number of consumers, therefore, these factors need to be considered together as main problems in use.

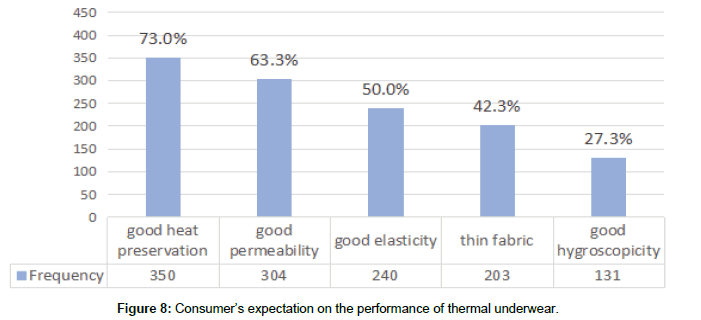

Consumers’ expectations for the performance of thermal underwear

From Figure 8 it can be seen that over 70% of the consumers expected to have thermal underwear with good heat preservation effect; meanwhile, more than half of the consumers were looking forward to purchasing thermal underwear with favourable permeability and elasticity. Besides, 42.3% votes were on ‘thin fabric’, and 27.3% votes were on ‘good hygroscopicity’.

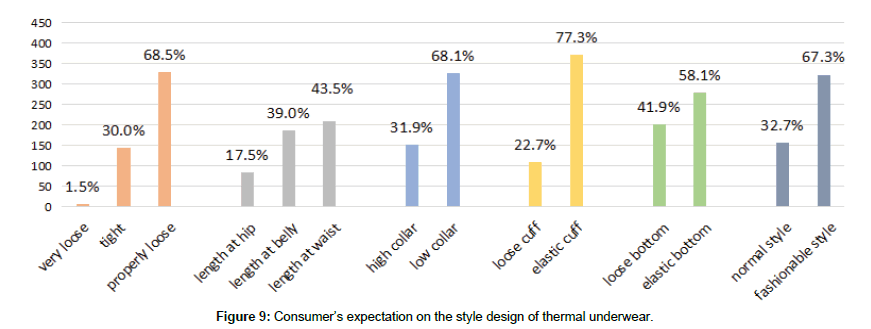

Figure 9 illustrates consumers’ expectations on thermal underwear’s style design. It can be seen that most of the consumers preferred to wear thermal underwear with proper loose quantity, waist-length low collar, elastic cuff and bottom, as well as fashionable style.

Expectations on other aspects

Questions about the new type of thermal underwear which can be worn outside in the public and questions of the product’s price were added in the questionnaires in order to fully understand consumers’ expectations.

In the section, 87% of the consumers were willing to wear outdoor type of thermal underwear, because of the convenience and wearing comfort. At the same time, as the new type of thermal underwear has favourable appearance, it can satisfy consumers’ aesthetic demands.

For product price, Figure 10 indicates that there were 47% of the consumers considering it to be a little high; 60% of the consumers suggested that the acceptable price for one piece of the thermal underwear should be between 100 to 300 yuan.

The Design of New Products

The design of the new fabric

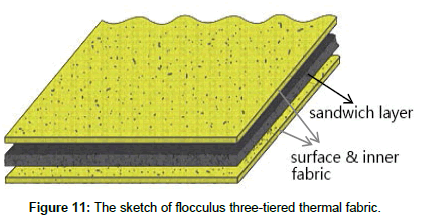

The structural design: As stated earlier, the fabric structure of thermal underwear can be roughly divided into three categories, namely, flocculus three-tier structure, fiber bundle three-tier structure, and the raising type structure. The first type of fabric structure, which consists of surface layer, inner layer and sandwich layer (flocculus), is chosen in this new fabric design stage. For fabric with three layers, in addition to the surface and inner fabric, the sandwich layer, which is flocculus, is the core part which provides the effect of heat preservation. The flocculus layer is usually made from selected raw fibers and single or multi-layer thin materials by mechanical bonding (spunlace and needle punching), heat bonding (hot rolling and drying), or chemical bonding. The single or multi-layer thin materials can be knitted fabric, non-woven fabric, and thin film.

Figure 11 is the sketch of flocculus three-tiered thermal fabric:

The composition: According to the comprehensive analysis of consumers’ demands on thermal underwear and the overall understanding of the performance of each material, the new fabric will use the following materials as its main components.

Surface fabric: Outlast air conditioning viscose fiber, combed cotton, terylene (contains bamboo fiber), wool, and spandex.

Inner fabric: Terylene (contains bamboo fiber), and spandex.

Sandwich layer: Hollow pet staple fiber as raw fiber, and knitted fabric as multi-layer thin material.

Component description

(1) Outlast air conditioning viscose fiber, which is made by micro-encapsulation technology, is a new kind of ‘smart’ fiber. It is manufactured by implanting the hydrocarbon wax, a heat sensitive phase-change material which can absorb and release heat, into fibers. Phase-change fibers can absorb heat by changing the form from solid to liquid when the outside temperature increases; on the contrary, when the outside temperature reduces, they can change from liquid to solid to release heat, so they are also called the intelligent air-conditioning fibers [21,28]. Therefore, fabric containing phasechange materials provides a comfortable ‘human body clothing microclimate’ by adjusting the surrounding temperature actively and intelligently.

Outlast air conditioning viscose fiber also has other important merits: it is as soft as cotton and silk, so it is very comfortable; it has good heat resistance and cooling effect; it has high hygroscopic and antistatic property; it is easy to dye; it has good drapability.

(2) Combed cotton is made by combing off shorter fibers and removing impurities from the cotton during spinning process. The final product made from combed cotton has smooth surface and good wearability. Combed cotton fabric has favourable permeability, well moisture absorption, fast-drying nature, and it is not easy to fuzzing and piling.

(3) Terylene has good elasticity which is close to wool, and it can almost fully resile after stretching. It also has excellent wrinkle resistance, well abrasion resistance, high fiber strength, and nice impact resistance.

(4) Bamboo fiber is called the fifth natural fiber after cotton, flax, wool and silk. It is extracted from bamboo, and it has good permeability and abrasion resistance; at the same time, it is natural antibacterial, odor-resistant, and uvioresistant. So it is a kind of natural environment-friendly green fiber.

(5) Wool has low thermal conductivity, and because of its naturally curly feature, it contains still air in the fiber, therefore, it has great heat retention. Wool has good permeability and hygroscopicity, and it can absorb a mass amount of moisture then release it slowly, to provide the cool feeling for the body. Wool also has high elongation, good elasticity, durability, antistatic property and odor remove function.

(6) The elastic elongation of spandex can reach up to 600% without influencing its restoring. Fabric with spandex has high elasticity and nice dimensional stability, so it provides good wearing comfort.

(7) Hollow pet staple fiber can reduce fiber’s thermal conductivity. With the high bulkiness, it increases the coverage rate per volume, which means it reduces the weight of each garment [28]. The fluffy structure contains still air which contributes to the favourable heat retention. Hollow pet staple fiber has high elasticity, large rigidity, and smooth feeling, so when it is used as the filling material, it can provide cool and warm feelings by wicking effect.

The style sketch and structure pattern of new products

It can be seen from the research findings that consumers were not satisfied with the existing thermal underwear in terms of its style and structure in the market. Most of them thought that the existing products were neither fit nor fashionable. They expected to have a piece of fashionable thermal underwear which could be worn in public, in this way, they could not only avoid the discomfort from layers of clothes but also get aesthetic satisfaction.

Two design schemes of female’s thermal underwear are shown below with their style sketches and structure patterns:

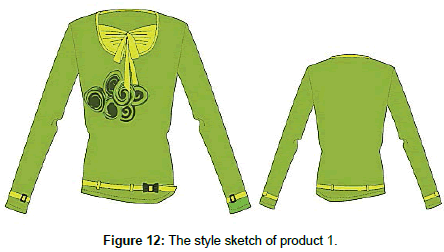

Product 1: Design description: the thermal underwear can be worn in public. It has moderate length, fashionable and slim appearance, pleated front fly made by soft and thin fabric which reflects feminine grace. Because of the natural feature of knitted fabric, the collar edge is naturally curly. The sleeve cuffs and the lower hem are elasticized and have velcro tab adjustments which improve the thermal performance. The front piece is decorated by prints, and asymmetrical hem increases the decorative perception of the garment. The style sketch of product 1 is shown in Figure 12.

The finished product specification of product 1 is shown in Table 1:

| Specification | Length | Bust | Outside sleeve | Armhole | Cuff opening | Collar width | Shoulder |

|---|---|---|---|---|---|---|---|

| 160/84 | 58 | 42 | 56 | 21 | 11 | 17 | 38 |

| Specification | Front neck drop | Back neck drop | Hemline | Collar edge roll width | Sleeve edge roll width | Shoulder slope | |

| 160/84 | 15 | 3.5 | 2.5 | 1.5 | 2.5 | 3 |

Table 1: The finished product specification (Unit:cm).

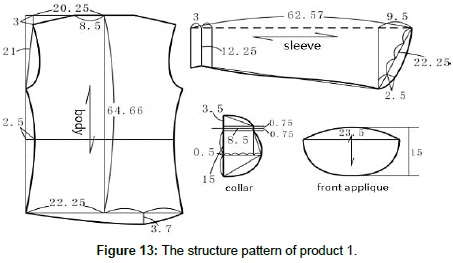

Garment structure dimensions calculation:

A. Sewing process loss: overlocking 0.75 cm, three-thread edge rolling 0.5 cm;

B. Sewing process shrinkage rate: 4.5%;

C. Dimensions of each piece:

Body: Length=(58+0.75+2.5+0.5)/(1-4.5%)=64.66 cm

Half Bust=(42+(0.75×2+1))/2=22.25 cm

Armhole=(21+0.75-0.75)=21 cm

Half Shoulder=38/2+0.75+0.5=20.25 cm

Sleeves: Outside Sleeve=(56+0.75+2.5+0.5)/(1-4.5%)=62.57 cm

Sleeve Armhole=21+0.75+0.5=22.25 cm

Cuff Opening=11+0.75+0.25=12.25 cm

Collar: Front Neck Drop=15 cm

Back Neck Drop=3.5 cm

Half Collar Width=17/2=8.5 cm

Figure 13 is the structure pattern of product 1:

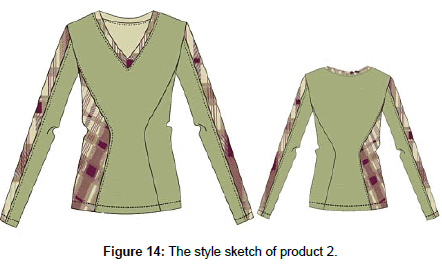

Product 2: Design description: the thermal underwear can be worn inpublic. The design comes from the idea of joining together different fabrics with various textures and patterns, to achieve the effect of fit and freshness. It uses V neck style and fabrics with large color differences to give people visual impacts. Asymmetrical patchwork and curve cutting lines are on both sides of the garment to show female’s curves and beauty. The style sketch of product 2 is shown in Figure 14.

The finished product specification of product 2 is shown in Table 2:

| Specification | Length | Bust | Outside sleeve | Armhole | Cuff opening | Collar width | Shoulder |

|---|---|---|---|---|---|---|---|

| 160/84 | 59 | 42 | 56 | 21 | 11 | 16 | 38 |

| Specification | Front neck drop | Back neck drop | Hemline | Collar edge width | Sleeve edge width | Shoulder slope | |

| 160/84 | 13 | 3 | 2.5 | 2.5 | 2.5 | 3 |

Table 2: The finished product specification (Unit:cm).

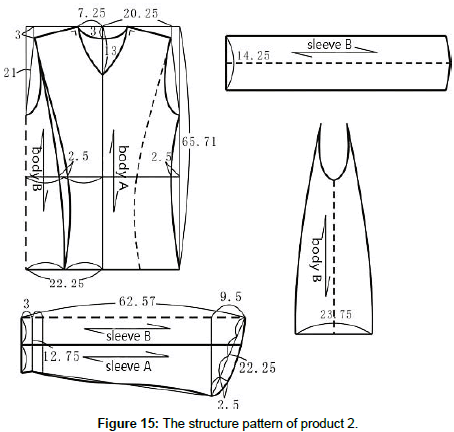

Garment structure dimensions calculation:

A. Sewing process loss: overlocking 0.75 cm, three-thread edge rolling 0.5 cm;

B. Sewing process shrinkage rate: 4.5%;

C. Dimensions of each piece:

Body: Length = (59+0.75+2.5+0.5)/(1-4.5%) = 65.71 cm

Half Bust = (42+(0.75×2+1))/2 = 22.25 cm

Armhole = (21+0.75-0.75) = 21 cm

Half Shoulder = 38/2+0.75+0.5 = 20.25 cm

Sleeves: Outside Sleeve = (56+0.75+2.5+0.5)/(1-4.5%) = 62.57 cm

Sleeve Armhole = 21+0.75+0.5 = 22.25 cm

Cuff Opening = 11+0.75×2+0.25 = 12.75 cm

Collar: Front Neck Drop = 13+0.75-0.75 = 13 cm

Back Neck Drop = 3+0.75-0.75 = 3 cm

Half Collar Width = 16/2-0.75 = 7.25 cm

Figure 15 is the structure pattern of product 2:

Conclusions

According to the research, the main findings can be concluded as below:

1. There was blindness in consumers’ purchasing process for thermal underwear.

It is obvious in the research that consumers mainly selected thermal underwear with personal feelings and the listed materials, which indicates that they were lacking in scientific and correct methods in the selecting process of thermal underwear.

2. There were many problems during the long-term usage of thermal underwear.

Problems mainly reported in the research were the decline of heat preservation effect, decrease of elasticity, poor permeability, thick fabric, and bad styling. New product development should aim at locating the defects or avoiding the weaknesses in the garment performance.

3. Further improvement should be made in garment performance and in price control.

From the research analysis it can be concluded that, based on overall consideration of consumers’ demands, fabrics of thermal underwear are expected to be thin, well elastic, and permeable; the garment structures are expected to be with low collar, elastic cuff and bottom, proper length, and fashionable style which can be worn outside. In terms of price, the pricing is suggested to be lower than 300 yuan for one piece of thermal underwear.

Recommendations and Suggestions

Strengthen the propaganda of knowledge about thermal underwear

Consumers’ purchasing blindness in thermal underwear mostly comes from the lack of knowledge about the product. Therefore, helping consumers to establish a correct concept of thermal underwear is very important.

Understanding the working theory of thermal underwear helps consumers choose the required products quickly and correctly. For instance, in addition to the clothing style and the fabric thickness which can be told by the appearance, the most significant feature should be understood is that the heat preservation materials in thermal underwear influence their warm effect the most.

Network propaganda

Nowadays, the popularization of network makes the transmission of information easier and quicker. So the performance knowledge of thermal underwear can be spread through network. To avoid unprofessional information, a specialized network publicity system should be built. By expert controlling filter, only professional and targeted information is accepted. All information then needs to be summarized and classified by experts to turn the theory into practice. The system can offer useful guidance to consumers who are confused during their thermal underwear purchasing.

Interpersonal propaganda

During interpersonal propaganda, consumers can receive related information of thermal underwear more directly. Therefore, the public can organize face-to-face experts’ propaganda lectures or send leaflets in shopping malls to spread useful information. Also, consumers experienced in choosing thermal underwear can be invited to share their shopping experience. Audiences are allowed to learn practical methods during the question and answer session in a pleasant ambience.

New products development

It can be seen that consumers are not satisfied with the present products in the thermal underwear market. Therefore, new products are expected to be developed with new fabric structures for better thermal effects and new fashionable styles for wearing in public places. Besides the two new product examples given in the last section, there are many other possibilities for the further improvement of thermal underwear. Only by understanding the demands of target consumers can the manufacturers produce the better products and gain a larger market.

Manufacturing cost reduction and sales price control

Product’s price influences consumers’ purchasing behaviors directly. The prices of thermal underwear in present markets are various from brand to brand, and some good products are losing their consumers due to a high price.

There are many reasons for the high price of thermal manufacturing processes which are expensive. However, hi-tech materials are not necessary to be utilized everywhere in the garment. In fact, many fungible low cost fibers with similar thermal effects have been found by experts. With an overall consideration, manufacturers of thermal underwear should put the hi-tech materials in critical areas while using the similar materials in other places in order to control the cost without influencing the wearing effect.

To increase the aesthetic, the decorating craftsmanship, such as prints, lace and embroidery, is suggested to be used in small areas, instead of a large amount of complicated technologies.

References

- Fukazawa T, Lee G, Matsuoka T, Kano K, Tochihara Y (2004) Heat and water vapour transfer of protective clothing systems in a cold environment, measured with a newly developed sweating thermal manikin. Eur J Appl Physiol 6: 645-648.

- Li Y, Zhang X, Yang B, Zhang S (2016) Thermal safety assessment test of permeable chemical protective clothing. Man-Machine-Environment System Engineering 406: 295-302.

- Núñez MWQ, Messias IA, Bartholomei CL (2016) Ergonomics in clothing: importance of thermal comfort in a typical Brazilian refrigerator of beef industry. Advances in Ergonomics Modeling, Usability & Special Populations 486: 291-297.

- Gavhed CED, Holmer I (1996) Physiological and subjective responses to thermal transients of exercising subjects dressed in cold-protective clothing. European Journal of Applied Physiology and Occupational Physiology 73: 573-581.

- Ueda H, Inoue Y, Araki T, Matsudaira M (1996) Clothing microclimate temperatures during thermal comfort in boys, young and older men. International Journal of Biometeorology 39: 127-132.

- Lu Y, Wang F (2015) Clothing resultant thermal insulation determined on a movable thermal manikin. Part I: effects of wind and body movement on total insulation. Int J Biometeorol 10: 1475-1486.

- Lee YH, Tokura H (1993) Seasonal adaptation of thermal and metabolic responses in men wearing different clothing at 10°C. Int J Biometeorol 1: 36-41.

- Lizák P, Mojumdar SC (2015) Influence of the material structure on the thermal conductivity of the clothing textiles. J Therm Anal Calorim 119: 865-869.

- Huang J (2008) Calculation of thermal insulation of clothing from mannequin test. Measurement Techniques 4: 428-435.

- Mao A, Luo J ,Li Y, Wang R, Li G, Guo Y (2011) Engineering design of thermal quality clothing on a simulation-based and lifestyle-oriented CAD system. Eng Comput 27: 405-421.

- Byrne C (2000) In Handbook of Technical Textiles. Woodhead Publishing Ltd, Cambridge, England.

- Schwartz P (2008) Structure and mechanics of textile fiber assemblies. Woodhead Publishing Ltd, Cambridge, England.

- Holme I (2007) Innovative technologies for high performance textiles. Coloration Technology 123: 59-73.

- Zhang Z, Li Y, Gong C, Wu H (2002) Casual wear product attributes: A Chinese consumers’ perspective. Journal of Fashion Marketing and Management 6: 53-62.

- Liu Z (2012) A survey of outdoor sportswear requirement for Chinese consumers. Adv Mat Res 479-481, 676-679.

- Sinclair R (2014) Textiles and Fashion: Materials, Design and Technology. Woodhead Publishing Ltd, Cambridge, England.

- Kadolph SJ (2010) Textiles. Pearson, London, UK.

- Ruckman JE, Murray R, Choi HS (1999) Engineering of clothing systems for improved thermophysiological comfort: The effect of openings. International Journal of Clothing Science and Technology 11: 37-52.

- Mcneill L, Moore R (2015) Sustainable fashion consumption and the fast fashion conundrum: fashionable consumers and attitudes to sustainability in clothing choice. Int J Consum Stud 39: 212-222.

- Tiwari M (2010) Thermal comfort of textile materials and its assessment.

- Satsumoto Y, Murayama C, Takeuchi, M (2009) Effect of moisture sorption of underwear material on clothing microclimate in a hot environment. Heat Transfer–Asian Research 38: 1-14.

- Morooka H (2000) Effects of hygroscopicity or water adsorption on wearing performance of clothing. Sen’i Gakkaishi 56: 352-357.

- Chen TH, Lin CL, Wang MJJ (2014) The evaluation of double-layer clothing in a semiconductor manufacturing environment. Human Factors and Ergonomics in Manufacturing & Service Industries 24: 207-215.

- Schmid M, Annaheim S, Camenzind M, Rossi RM (2016) Determination of critical heat transfer for the prediction of materials damages during a flame engulfment test. Fire and Materials 40: 1036-1046.

- Olesen BW, Hasebe Y (1987) Thermal environment and clothing comfort. Sen’i Gakkaishi 43: 210-221.

- Kamalha E, Zeng YC, Mwasiagi JI, Kyatuheire S (2013) The comfort dimension; a review of perception in clothing. Journal of Sensory Studies 28: 423-444.

- Lovell DR (1995) High-Performance Polymer Fibre Yarn & Fabric. In: Carbon and High Performance Fibres Directory and Databook, Springer, Dordrecht.

- Sular V, Okur A (2007) Sensory evaluation methods for tactile properties of fabrics. J Sens Stud 22: 1-16.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi