Research Article, J Fashion Technol Textile Eng S Vol: 0 Issue: 4

Smart Solutions to Improve Wearing Comfort

Manuela Bräuning1*, Julia Eva Frick1, Julia Melnikov1, Jörn Lübben2, Axel Keck2 and Charles Tchouboun2

1Department of Textile and Clothing Technology, Faculty of Engineering, University of Applied Sciences Albstadt-Sigmaringen, Germany

2Department of Material and Process Engineering, Faculty of Engineering, University of Applied Sciences Albstadt-Sigmaringen, Germany

*Corresponding Author : Manuela Bräuning

Department of Textile and Clothing Technology, Faculty of Engineering, University of Applied Sciences Albstadt-Sigmaringen, Germany

Tel: +0049 (0) 7571-732 9276

E-mail: braeuning@hs-albsig.de

Received: December 11, 2017 Accepted: February 27, 2018 Published: March 02, 2018

Citation: Bräuning M, Frick JE, Melnikov J, Lübben J, Keck A, et al. (2018) Smart Solutions to Improve Wearing Comfort. J Fashion Technol Textile Eng S4:011. doi: 10.4172/2329-9568.S4-011

Abstract

Human performance often depends on the wearing comfort of the clothing system under challenging climatic conditions. This has led researchers to explore various approaches to improving wearing comfort and trying to understand thermophysiological processes.The field of thermophysiology is most important in Sporttech, Medtech, and Protech applications, where clothing system performance is especially critical. We, the RespothermTex team, have conducted research concerning microclimate conditions and using thermoresponsive polymers to automatize the transport of warmth and humidity through a clothing system. This technology opens the possibilities for smart multifunctional clothing systems.

Keywords: Wearing comfort; Thermophysiological properties; Microclimate; Thermoresponsive polymers

Introduction

The well-being of humans is closely linked to the climatic conditions in the surroundings, so humankind has always tried to provide help with clothing. The altered awareness of health and individuality leads to changes in requirements for clothing. In addition, an increasing number of people is becoming more aware of environmental issues whilst requirements regarding functionality and cost continue to rise. This opens a wide field of possibilities for innovation.`

Depending on the end-user and usage scenario, different clothing systems are required. A clothing system in this context is defined as different pieces of clothing which interact e.g. the base layer, the insulation layer as well as the wind and waterproof shell. Good clothing systems should provide the function of protecting the body from cooling or from overheating, and ensure optimal wearing comfort due to an optimal adaptation to the prevailing conditions. Clothing systems are most often used for personal protective equipment, in medical applications or within the area of sports and outerwear [1,2].

The exigencies to the textile-based equipment have increased continuously. Therefore, the industry has to rise to the challenge to develop equipment with integrated supplementary functions, so called smart solutions. A smart solution leads to a product with added value for the user. This can be an improvement in materials, design, construction or manufacturing, though adding another component can be beneficial too. The wish to have multifunctional clothing systems leads indeed to research and extended development times.

Wearing Comfort

Based on literature and patent research combined with latest research results from the University of Applied Sciences Albstadt- Sigmaringen, the lecture will provide an overview of various technologies to improve wearing comfort in clothing systems.

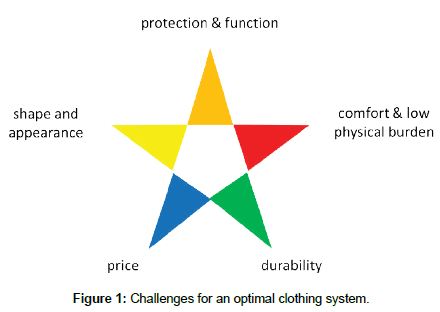

A clothing system has to face the challenge to be the best compromise between different competing properties, which are illustrated in the Figure 1.

The wearing comfort itself is differentiated in four categories:

• Thermo-physiological comfort,

• Sensorial comfort,

• Ergonomic comfort,

• Psychological comfort as well as aesthetic appeal.

Due to low efficiency of physical work from humans, heat stress occurs quickly. Almost 80% of the total energy is heat as a by-product, which has to be led away from the body. This process is realized by radiation, convection, conduction and evaporation (perspiration and sweating). Therefore, especially the field of thermophysiological comfort is of particularly high concern regarding the wearer’s performance and safety. For that reason, this research work focuses on the thermo-physiological comfort [3,4].

Besides i.e. active cooling systems, improved patternmaking or ventilation openings, there is a wide range of smart textiles entering the market to fulfil the more and more complex customer needs. Phase change materials (PCM) [5] or the C-Change membrane by Schoeller Technologies [6] are examples to actively influence the thermo-physiological comfort.

Application of thermoresponsive polymers

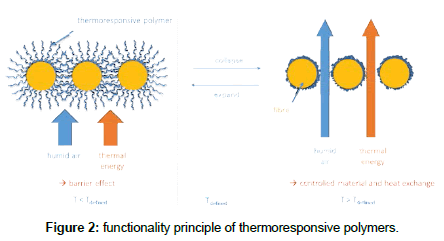

The research group RespothermTex from the University of Applied Sciences Albstadt-Sigmaringen pursues a different approach. The goal is to improve the thermophysiological comfort by using a smart way to automatize the transport of warmth and humidity through a clothing system by using thermoresponsive polymers.

Those polymers are able to decrease in volume if the temperature rises above a certain level. As soon as the temperature decreases below this level this process is reversed and the polymer expands. Chemist define this temperature (Tdefined) as the lower critical solution temperature (LCST). The LCST of thermoresponsive polymers in general depend on polymer degree of polymerization and polydispersity. The associated changes in shape make them ideal candidates for smart materials, e.g. for thermal and moisture control in textiles.

The Figure 1 shows the challenges of a clothing system and Figure 2 show this reversible process in principle. The interdisciplinary project team started in 2015 with the screening of commercialized thermoresponsive polymers, design and synthesis of new polymers. It then went on to the screening and chemical functionalization of suitable substrates through surface treatment and application of polymers on substrates. At the moment, the testing and optimization of functionalized samples is ongoing. In order to define the LCST range a study on the microclimatic conditions was performed.

Microclimate in clothing systems

To design applicable solutions for various end-user scenarios, it is necessary to understand the interdependence of the microclimates between the different layers of textiles. To keep the wearer in the best possible condition, it is necessary to avoid condensation in between the layers of a textile system. This is of highest importance to prevent the wearer from early fatigue and to increase their safety in challenging situations, especially in hazardous working environments or during a competition.

Therefore, a study to interlayer climatic conditions was conducted with five male subjects at the age of 20 to 30 at the University of Applied Sciences Albstadt-Sigmaringen. The aim of this study was to gain a more profound insight into temperature and humidity conditions within a clothing system. Moreover, the results collected during this trial are used to define the temperature and humidity range for the research approach of improving the wearing comfort through the use of thermoresponsive polymers.

The test setup was on a treadmill at 23°C and 50% r. h. with the following protocol:

1. 5 minutes “warm-up“ with 60 – 65% of individual maximal heart rate

2. 15 minutes “basic endurance“ with 65 – 75% of individual maximal heart rate

3. 5 minutes “muscular endurance“ with 75 – 90% of individual maximal heart rate

4. 5 minutes “cool-down“ with 60 – 65% of individual maximal heart rate

Sensors to collect temperature and moisture were placed on the back, the chest and the forearm of the examinee. They wore a combination of a base layer and two different jackets – one with a barrier layer based on a dot laminated membrane, the other barrier layer based on a coating. The evaluations show a broad variety of temperatures and humidity on the different testing spots. This supports the concept of body-mapping to adapt the textile system to the different needs. A barrier layer within the clothing system leads to higher temperature, which consequently leads to more sweat and in the end to discomfort. This shows that the porosity and resistance properties of the textile layers are playing a major role, which has to be considered for the design development.

Conclusions and Outlook

Multifunctional clothing that is beneficial to the wearer is more and more required. The general aim of the research project RespothermTex is to improve the wearing comfort for a variety of user groups and different clothing systems. The adaptation of the thermoresponsive polymer to a defined LCST for different applications will lead to the design and product development of new innovative smart textiles, which can adapt to different surroundings actively.

The presented developments show that there is still a lot of research work required in order to understand the mechanisms inside clothing systems, before developing self-adaptive clothing systems for a highly competitive market. Therefore, one of the key factors is interdisciplinary teamwork integrating the future end-user in the development process to create reliable and multi-functional equipment that is fit for meeting individual daily challenges.

Acknowledgement

The German Federal Ministry of Education and Research (BMBF) promotes interdisciplinary research and development projects in the disciplines of engineering, natural sciences and economics, where universities of applied sciences cooperate with partners from business and science. The ongoing research project RespothermTex (support code FKZ: 13FH060PX4) started in September 2015 and will last until August 2018. The project team works together with the research company “Forschungsgesellschaft für Textiltechnik Albstadt” and the technical universities of Aachen and Dresden. The project RespothermTex gets approx. 648.000 Euro financial support by the FHprofUnt2014 initiative.

References

- Barker R (2011) Improving comfort in clothing. Woodhead Publishing, Cambridge, UK.

- Bartels VT (2005) Physiological comfort of sportswear in Textiles in sport. Woodhead Publishing, Cambridge, UK

- Roy AK, Choudhury (2011) Improving comfort in clothing. Woodhead Publishing, Cambridge, UK.

- Das A, Alagirusamy R (2010) Science in Clothing comfort, Woodhead Publishing India Pvt. Ltd., New Delhi, India.

- Fendt B (2017) Outlast Europe GmbH. Productpilot.

- Schoeller Technologies (2017) Functional, protective, knitted and technical textiles.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi