Research Article, J Fashion Technol Textile Eng Vol: 7 Issue: 2

The Influence of Alkaline Hydrolysis and Plasma Treatment on PES Fabric for CNC/TiO2 Application

- *Corresponding Authors:

- Hayriye Gidik

UCL, Hautes Etudes d’Ingénieur (HEI)

GEMTEX, 13 rue de Toul, F-59000 Lille, France

Tel: 33618266990

E-mail: Hayriye.gidik@yncrea.fr

Received: August 30, 2019 Accepted: September 17, 2019 Published: September 25, 2019

Abstract

The past couple of years, buildings with low energy consumption and a higher thermal comfort have become more and more common but this has a negative impact on the Indoor Air Quality (IAQ). The majority of pollutants present in the indoor air are Volatile Organic Compounds (VOCs) that originate from many sources inside these buildings. The ultimate aim of this research activity is to functionalize a textile substrate (polyester (PES), woven fabric) with a hybrid photocatalytic material based on Cellulose Nanocrystals (CNC)/titanium dioxide (TiO2) in order to photodegrade VOCs under visible light. This study presents the first part of this research which focusses on the pretreatment of PES fabric with alkaline hydrolysis and plasma treatment in order to functionalize it with CNC/TiO2. The influence of these pretreatments on the binding of the CNC/TiO2 to the textile substrate is analyzed by using different characterization methods, i.e. contact angle measurements, FTIR-Attenuated Total Reflectance (FTIR-ATR), Energy-Dispersive X-ray (EDX) spectroscopy and Thermogravimetric Analysis (TGA). The results show that the pretreatments by alkaline hydrolysis and plasma enhance the binding of TiO2 to the PES fab

Keywords: Indoor air quality; TiO2; Cellulose nanocrystals; Polyester; Plasma; Alkaline hydrolysis

Introduction

Directive 2010/31/EU of the European Parliament states that from the 1st of January 2021 all new buildings in the European Union should incorporate energy saving measures and be “nearly zero energy buildings”. Passive buildings use different technologies, such as efficient insulation, advanced window technology, airtightness, and heat recovery techniques, in order to significantly reduce energy consumption. The international definition for passive buildings specifies the following criteria: space heating/cooling energy demands, primary energy demands, airtightness and thermal comfort (Passive House Institute, Germany). However, making buildings more airtight and presumably decreasing ventilation may have negative impact on the Indoor Air Quality (IAQ) [1,2].

As people in industrialized countries spend the majority of their time (over 90%) in various indoor spaces (houses, offices, schools, transport), the IAQ has become an important health and safety concern. IAQ depends upon the type and strength of sources of indoor pollution, the quality of outdoor air, and the effectiveness of ventilation at removing the pollutants generated indoors [3]. The majority of pollutants, which are present indoors, are Volatile Organic Compounds (VOCs) that originate from different sources; namely, building products (room furnishings, paints, glues, varnishes etc.) and occupant activities. Other air pollutants such as ozone or nitrogen dioxide are mainly generated in outdoor air and are brought indoors via ventilation. Other sources of indoor pollutants include both gaseous and surface chemical reactions that involve oxidants like ozone [4].

Indoor air treatment is a complex phenomenon because of the wide variety of potential pollutants and the low level of pollutant concentration. In addition to these, the airflow to treat these VOCs remains modest. The difficulty with this type of treatment is to find an efficient process with low-level selectivity and low cost (investment, energy and maintenance). Photocatalysis presents a real advantage for indoor air applications as it is able to treat low concentrations and flow rates [5]. The semiconductor photocatalysis, which is a green technology, has been widely applied in removing the organic pollutants from air. Especially semiconductor compounds like ZnO and TiO2 exhibit good photocatalytic activity under UV light irradiation, due to their relatively large band gap of about 3.37 and 3.20 eV, respectively [6].

During this study, we would like to functionalize a woven polyester (PES) fabric, which can be used as a curtain, with TiO2. A commercial TiO2 P25® (Evonik, Germany) was used for semiconductor photocatalysis. The novelty of this study is that a bio-based binder, Cellulose Nanocrystals (CNC), was preferred in order to encapsulate the TiO2 into the porous structure of CNC to increase the durability of TiO2 on textile substrate (washing, abrasion). In addition to this, CNC can protect the textile substrate from TiO2 catalysis. Thus, woven PES fabric was treated with CNC/TiO2 in order to eliminate VOCs by photocatalytic activity.

As PES fibers are hydrophobic in nature, they have poor wetting properties that influence highly their processability i.e. dyeing and finishing. Many efforts have been made to modify the surface of PES fibers with the aim to introduce new carboxylic and hydroxyl groups on the fiber surface to enhance the binding efficiency of TiO2. In literature, several methods, i.e. alkaline hydrolysis and plasma treatment, are proposed to modify PES fibers. Different types of plasma treatment can be used as it is a viable method for the superficial modification of fibers. The plasma treatment can also cause morphological changes, resulting in increased active surface area and roughness. These topographical changes are favorable for deposition of TiO2 [7-10]. On the other hand, the conventional alkaline hydrolysis can be used to enhance the binding efficiency of TiO2. It is well established that alkaline hydrolysis of PES fibers leads to considerable chemical and topographical changes of fibers where scission of polymer chains takes place. By doing this, the carboxylic and hydroxyl groups are introduced and this can be used to improve TiO2 binding [7,11]. In this study, PES fabric was treated with the conventional alkaline hydrolysis method and plasma treatment in order to prepare it for a better functionalization with the developed hybrid photocatalytic material (CNC/TiO2). By using these pretreatments, it was supposed to increase the adhesion of the CNC/ TiO2 on the PES fabric. The difference of this study from others is that two different methods (alkaline hydrolysis and plasma treatment) with several parameters were used and compared between them for the functionalization of PES. Two different procedures were used for plasma treatment by changing the time and thickness of treatment. Twelve different procedures were used for alkaline hydrolysis by changing didecyldimethylammonium chloride concentration, pH and treatment time. After these pretreatments, the hybrid photocatalytic material based on TiO2 and CNC were applied to the PES fabric by using padding technology. The efficiency of treatments was compared regarding to different methods of characterization, i.e. FTIR, TGA, SEM-EDX. Thus, this study combines several parameters presented separately in literature. It presents the preparation of a bio-based binder (CNC) and its combination with TiO2 by using two methods, i.e. sol-gel and dispersion methods. In addition to these, two different pretreatment methods,i.e. alkaline hydrolysis and plasma treatmentwere presented and compared in order to find out the optimal conditions for the functionalization of a PES fabric.

Materials and Methods

Materials

100% PES fabric with plain weave from Subrenat (France) was used as textile substrate. Triton® X-100, didecyldimethylammonium chloride from Fluka (Switzerland) and sodium hydroxide from Sigma Aldrich (USA) were used for washing and hydrolysis. A commercial TiO2 P25® (Evonik, Germany) was preferred in order to functionalize the textile substrates following the dispersion method while for the sol-gel method, titanium (IV) isopoxide (Acros Organics, 98+ % purity) was used as TiO2 precursor.

Methods

The procedures for alkaline hydrolysis, plasma treatment, preparation of CNC/TiO2 suspension and padding process are presented below.

i. Alkaline hydrolysis: The PES fabric with plain weave was washed with 2 g.L-1 Triton® X-100 and 2 g.L-1 sodium carbonate at 60°C during 1 hour. The samples were dried at 105°C during 5 min. Two different didecyldimethylammonium chloride concentrations, i.e. 0.1 g.L-1 and 0.5 g.L-1, were prepared at two different pH values, i.e. 9 and 12, for fiber treatment in order to find the optimal conditions. The sodium hydroxide was used in order to adjust the pH of solution. The samples were treated either 30 min or 90 min at 95°C with exhaustion and then they were rinsed. They were dried at 105°C for 5 min.

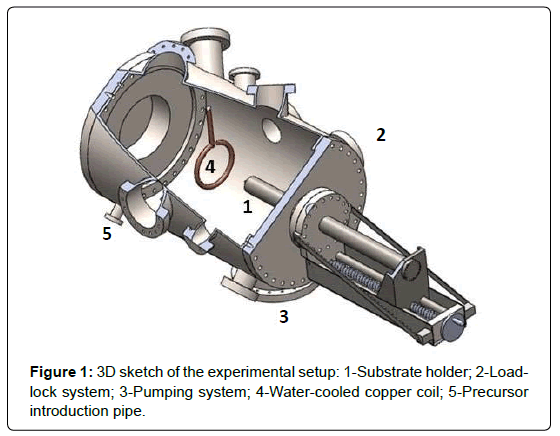

ii. Plasma treatment: Cyclopropylamine Plasma Polymer Films (CPPF) were deposited on the PES fabric to obtain stable amine function at the surface. The deposition chamber consists of a cylindrical stainless steel vacuum chamber (35.5 cm in diameter and 86.5 cm in length) equipped with a rotary pump (Varian Triscroll 600) and a turbomolecular pump (Oerlikon Leybold Vacuum MAG W 600 iP/L) connected in series, allowing to reach a residual pressure of 6.6x10-4 Pa, as measured by a full-range gauge (Figure 1). The liquid precursor (Cyclopropylamine ≥ 98.0% purity supplied from Sigma–Aldrich) was introduced in the chamber using a mass flow controller and an introduction system (Omicron) entirely heated at 323 K (container, tubes and connectors). During the process, the working pressure was accurately regulated by a throttle valve controlled by a capacitive gauge. The water-cooled copper coil (4.5 cm internal diameter and 0.7 cm thickness) was located in front of the substrate and connected to a RF power supply (13. MHz, Advanced Energy Cesar 1310) via a matching network (Advanced Energy VM1000A). The distance between the coil and the substrate was fixed at 13 cm. The substrates were introduced under vacuum through a load-lock system, and then transferred to the deposition chamber using a transfer stick. CPPF were synthesized using both Continuous Wave (CW) at 40W. All the experiments were made exclusively in the inductive mode, with the working pressure and the precursor flow rate fixed at 5.33 Pa and 5 sccm, respectively. Table 1 presents the parameters, i.e. pressure, power, debit, time and thickness, for the treatment. The treatment time and thickness were modified to analyze the influence on the efficiency. For each method, three samples were tested.

| Plasma | Pressure (Pa) |

Power (W) |

Debit (Sccm) |

Time (min) |

Thickness (nm) |

|---|---|---|---|---|---|

| 1 | 5.33 | 40 | 4 | 4 | 25.0 |

| 2 | 5.33 | 40 | 4 | 2 | 12.5 |

Table 1: Plasma treatment parameters.

iii. Preparation of CNC/TiO2 suspension: CNCs were obtained by the acid hydrolysis of cotton wool as described elsewhere [12]. Typically, 50 g of cotton wool (Hartmann Watte, Germany) was hydrolyzed in 450 mL of a 64 wt% sulfuric acid (VWR Chemicals, USA) solution at 45â°. The slurry resulting from the hydrolysis was diluted subsequently with deionized water follow by centrifugation, dialysis against tap water, sonication, ion exchange and filtration to give the cellulose nanocrystals suspension which was concentrated using a rotational evaporator to reach any targeted concentration. Two different methods were used for the preparation of CNC/TiO2 suspension: a dispersion and a sol-gel method. For the dispersion method, 0.7 g TiO2 P25® was mixed with 100 mL (2.8 wt%) CNC suspension using a high-shear disperser (Ultra-Turrax, IKA) operated at a speed of 7000 rpm during 15 min at room temperature. Afterwards, the suspension was sonicated in an ultra-sonication bath (BANDELIN, Germany) for 15 min at room temperature. For the solgel method, the TiO2 was prepared by a low-temperature sol-gel route [13] and combined with CNC suspension. The mass ratio of CNCs to TiO2 was about 1:1 (0.8 wt% TiO2 and 0.8 wt% CNC).

iv. Padding process: The CNC/TiO2 suspensions prepared by either the dispersion or the sol-gel method were applied to the samples which were pretreated by plasma or alkaline hydrolysis, respectively. In order the see the influence of pretreatments, CNC/ TiO2 suspensions prepared by the sol-gel method were applied to a non-pretreated PES substrate. For the padding process, the applied pressure was 2 Bar and the speed of the rollers was 7 rpm. After the padding process, the samples were dried and cured at 105°C and at 150°C for 5 min, respectively.

Characterization

Four different methods were used for characterization of samples: contact angle measurements, FTIR-Attenuated Total Reflectance (FTIRATR), Scanning Electron Microscope (SEM)/Energy-Dispersive X-ray (EDX) spectroscopy and Thermogravimetric Analysis (TGA).

Contact angle measurements

In order to compare different alkaline hydrolysis processes presented previously, the contact angle measurements were realized using distilled water. An optical microscope (Zeiss, Germany) with SPOT Basic software was used to get images and they were treated by using ImageJ software.

ATR

ATR spectra of the TiO2, CNC, non-treated, alkaline hydrolyzed, plasma treated and functionalized PES fabrics were characterized by IR spectroscopy (Varian, USA). The samples were analyzed in reflectance mode in the range of 400–4000 cm−1 . Each spectrum was collected by cumulating 64 scans at a resolution of 4 cm−1 . The experimental data was collected and analyzed using the Varian Resolutions Pro software. Each sample was analyzed three times.

SEM/EDX

A Scanning Electron Microscopy coupled with an Energy Dispersive X-ray spectroscopy (SEM/EDX) was used to analyze chemical composition of CNC/TiO2 treated samples. Characterizations were performed by a FE-SEM (Hitachi SU8020 Ultra-High Resolution Scanning Electron Microscope) equipped with an EDX detector (Htermo Scientific Ultradry Noran System 7).

TGA

A commercial TiO2 P25® and CNC samples were characterized separately by using TGA 4000 thermogravimetric analyzer (Perkin Elmer, USA) in the temperature range of 30-900°C. Alkaline hydrolyzed, plasma treated and functionalized PES samples were characterized with same analyzer in the temperature range of 30-700°C. The heating rate was maintained at 10°C.min-1. The measurements were made under a constant air flow rate of 20 mL.min-1. The experimental data was collected and analyzed using the Perkin Elmer Pyris Manager software. Each sample is characterized three times in order to confirm the repeatability of the measurement and homogeneity of the treatments.

Results and Discussion

Choice of optimized hydrolysis process

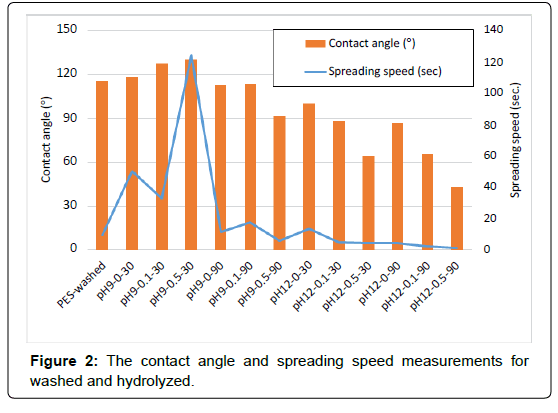

The Figure 2 presents the measured contact angles and spreading speeds after the different hydrolysis processes. As it was explained previously, two different didecyldimethylammonium chloride concentrations, i.e. 0.1 g.L-1 and 0.5 g.L-1, at two different pH values, i.e. 9 and 12, and for two different treatment times, i.e. 30 min and 90 min, were used for optimization.

As it is clear from Figure 2, the PES becomes much more hydrophilic with increasing pH, thus under more alkaline conditions. Hence, pH 12 was chosen for future studies. The decreasing contact angle and spreading speed confirmed that the increasing didecyldimethylammonium chloride concentration and treatment time had a positive influence on the hydrophilicity for pH 12. Thus, the fabric which was hydrolyzed with 0.5 g.L-1 didecyldimethylammonium chloride and pH 12 at 95°C for 90 min (pH 12-0.5) was chosen for the padding process.

ATR

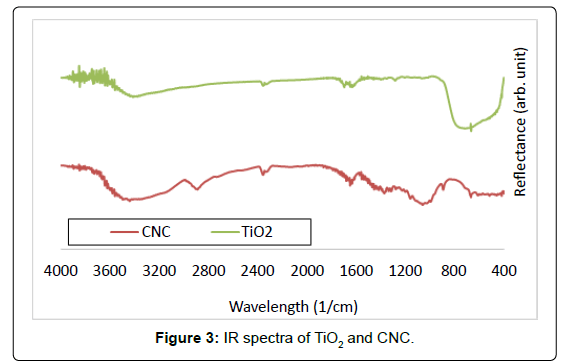

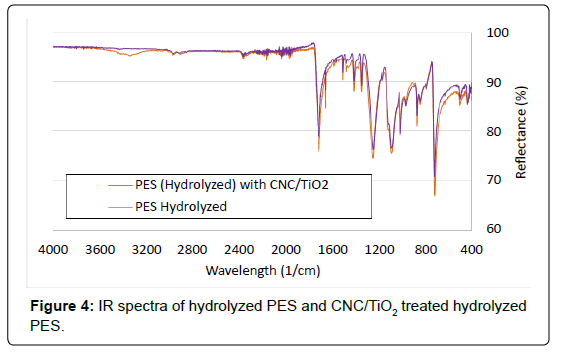

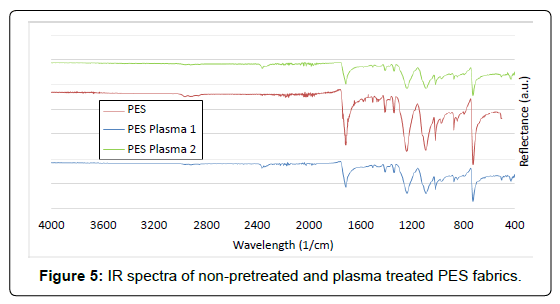

Each product was characterized separately and the results were compared with functionalized textiles. The Figure 3 presents the spectra of titanium dioxide (TiO2 P25®) and Cellulose Nanocrystals (CNCs). ATR spectra of the CNC showed bands at 3400 cm−1 and 2897 cm−1 indicating the stretching vibration of OH and the CH stretching vibration, respectively. The intense band at 1621 cm−1 indicated the presence of CO stretching vibration of cellulose rings as well as OH bending vibration of absorbed water molecule and the 1028 cm−1 band is related to the C−OH stretching vibration of secondary and primary alcohols of cellulose. In addition, it is worthwhile to note peak at 614 cm−1 indicates the C−OH out of plane bending vibration [14]. In case of TiO2, the broad vibration band between 3650 and 2600 cm−1 is associated with the OH stretching mode of water molecules (physisorbed molecular water), while that at 1620 cm−1 is assigned to their bending modes. The bands in the range 1600-1300 cm−1 are generally associated with carbonate groups; thus, the bands at around 1420 cm−1 are assigned to carbonate species formed by the adsorption of atmospheric CO2. The absorption in the range 1000-600 cm−1 is due to the surface vibrations of the Ti-O bonds [15]. The Figure 4 presents the IR spectra of hydrolyzed PES fabric and CNC/TiO2 treated hydrolyzed PES fabric. The spectrometric analysis showed the presence of CNC at around 3400 cm-1 and TiO2 at around 600 cm-1 on the PES fabric comparing to Figure 3.The PES fabric before and after plasma treatment were characterized in order to see the presence of the added primary amine groups. The Figure 5 presents the spectra of non-pretreated and plasma treated PES fabrics. According to Yang et al. the peaks of the primary amine NH2 stretching absorption and the C=N stretching absorption should be observed at the 3500–3300 cm−1 and 1630–1660 cm−1 regions, respectively [10]. However, Figure 5 does not show any difference between PES and plasma treated PES samples. It can be supposed that the amount of added primary amine groups does not absorb enough to be detected by this method.

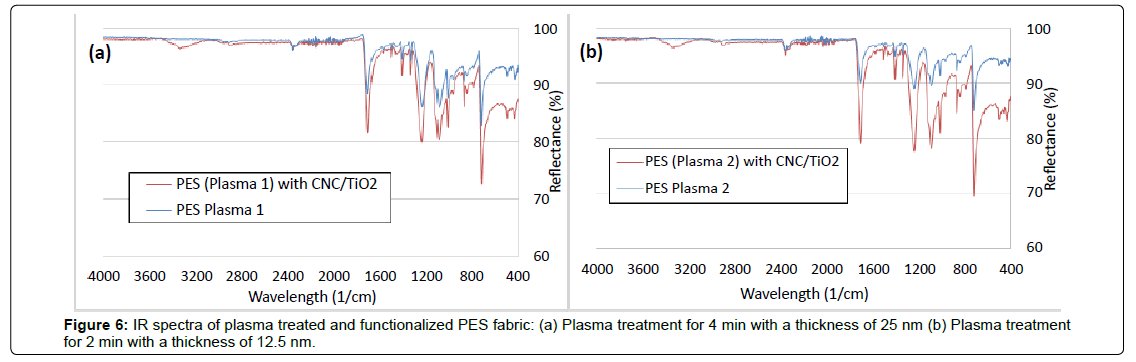

The same characterization procedure was followed for plasma treated and functionalized samples in order to see the synergy between pretreatment and the functionalization process. The Figure 6 presents the spectra of plasma treated and functionalized PES fabrics.

The results with plasma treated samples (Table 1) gave similar results as the hydrolyzed samples for the presence of CNC and TiO2. However, it is quite difficult to compare the plasma 1 treated sample with plasma 2 treated sample for the efficiency of the functionalization with CNC/TiO2. Thus, these first results were enhanced with SEM/ EDX and TGA analysis on order to have quantitative results.

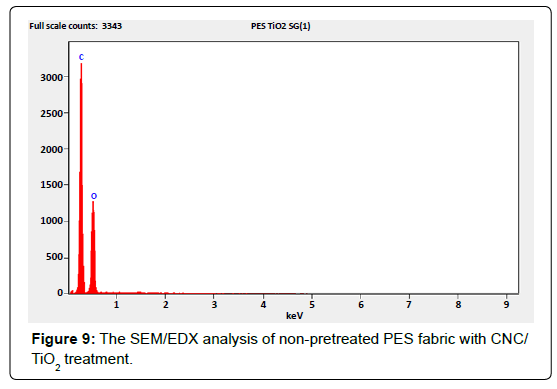

SEM/EDX

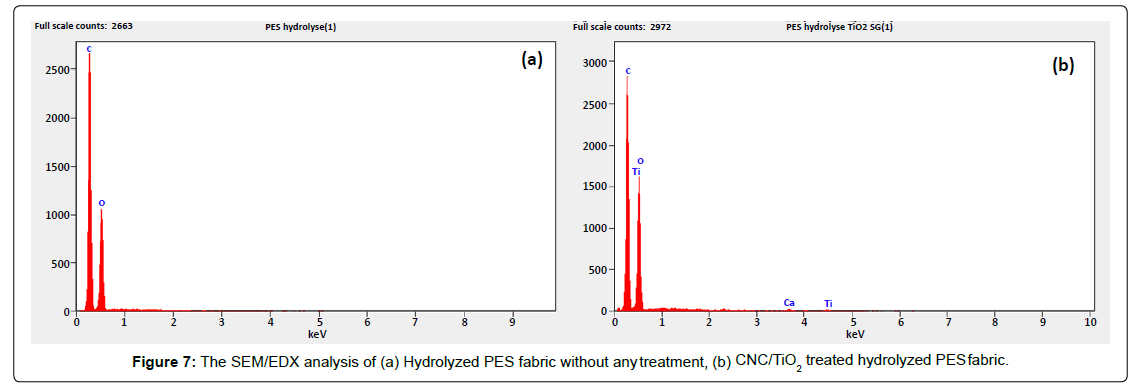

The Figure 7 presents the SEM/EDX analysis of the hydrolyzed and hydrolyzed–functionalized PES fabric. As it can be seen from Figure 7 (a), hydrolyzed PES fabric without any treatment does not present any Ti, however the presence of TiO2 on the fabric is shown after hydrolysis and functionalization with CNC/TiO2.

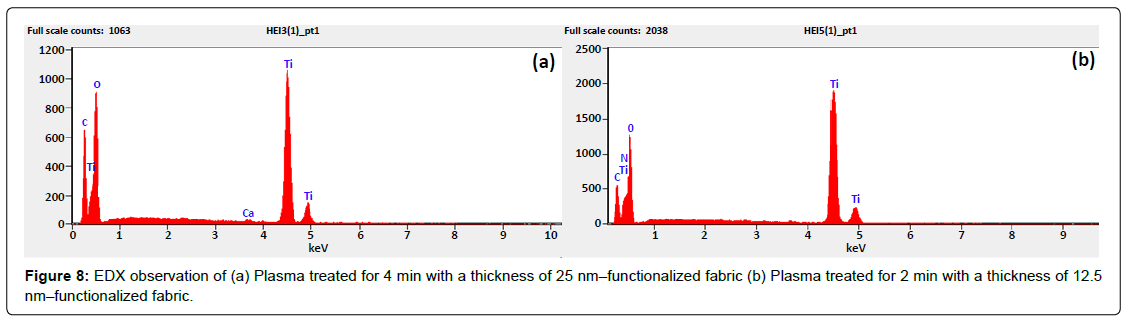

The Figure 8 presents the SEM/EDX analysis of plasma treated– functionalized PES fabrics.

The Figure 8 confirms the presence of Ti particles on PES fabric after plasma treatments. It can be concluded that the plasma treatment enhances the binding of TiO2 to the PES fabric as alkaline hydrolysis.

In order to confirm the influence of the alkaline hydrolysis and the plasma treatment on the functionalization process, PES fabric without any pretreatment was treated with CNC/TiO2 which is prepared with dispersion method by using padding process. The Figure 9 presents the SEM/EDX analysis of the non-pretreated – functionalized PES fabric.

As it can be seen from Figure 9, no Ti-containing particles were retained on the fabric after functionalization with CNC/TiO2 without pretreatment of the substrate, meaning that the pretreatments by alkaline hydrolysis and plasma treatment enhance the binding of TiO2 to the PES fabric certainly by introducing new carboxylic and hydroxyl groups to the fiber surface and changing the topology of the surface. These first results from SEM/EDX analysis confirmed that the functionalization is not efficient without alkaline hydrolysis and plasma treatment. With SEM/EDX observations, it is complicated to compare two plasma treatments for their efficiency in order to understand the influence of the treatment time and thickness and also have quantitative results. Thus, functionalized PES fabrics were characterized by TGA to confirm the results obtained by SEM/EDX.

TGA

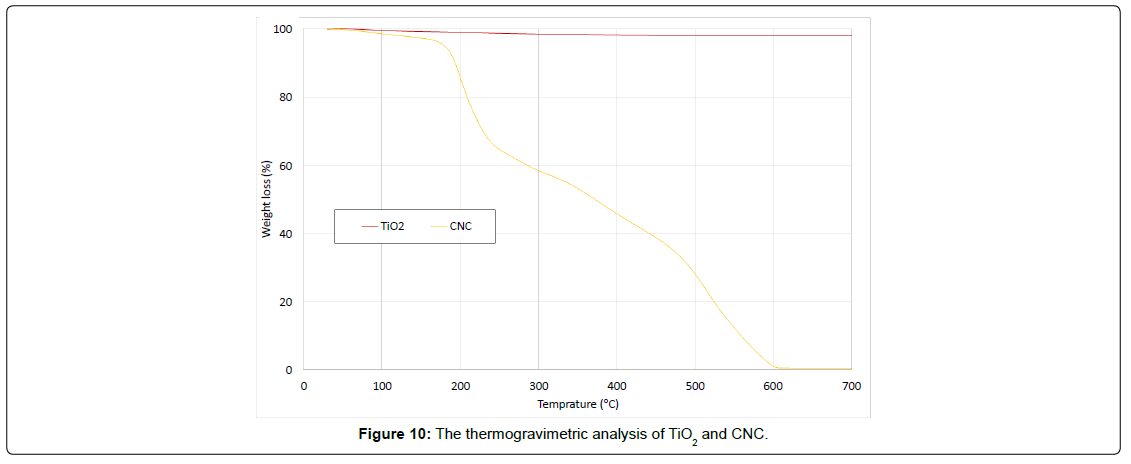

The Figure 10 presents the thermogravimetric analysis of titanium dioxide (TiO2) and cellulose nanocrystals (CNC), separately.

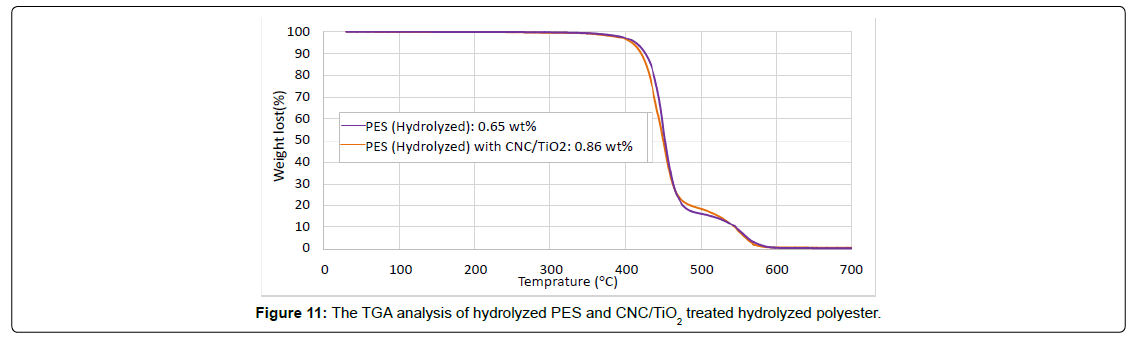

As the TiO2 is a metal oxide, its degradation temperature is higher than 600°C. Thus, it did not show any change in weight until 900°C. However, CNC presented a weight loss from 160°C to 600°C and it was completely burnt off to a 0% residual mass at around 600°C. The Figure 11 presents one of the results out of three for the thermogravimetric analysis of hydrolyzed PES fabric and CNC/TiO2 treated hydrolyzed PES fabric.

The thermogravimetric analysis showed that the degradation of fabrics started at around 340°C and reached amaximum rate around 60°C. From 580°C onwards, the weight loss was 0.65 ± 0.01% for hydrolyzed PES fabric. However, the weight of residue was 0.82 ± 0.04% with respect to the initial fabric weight for CNC/TiO2 treated hydrolyzed PES fabric at 700°C. As it was presented previously (Figure 10), the CNC was fully degraded at 600°C while TiO2 remained stable at this temperature. Thus, this 0.17% represents the quantity of TiO2 on fabric surface.

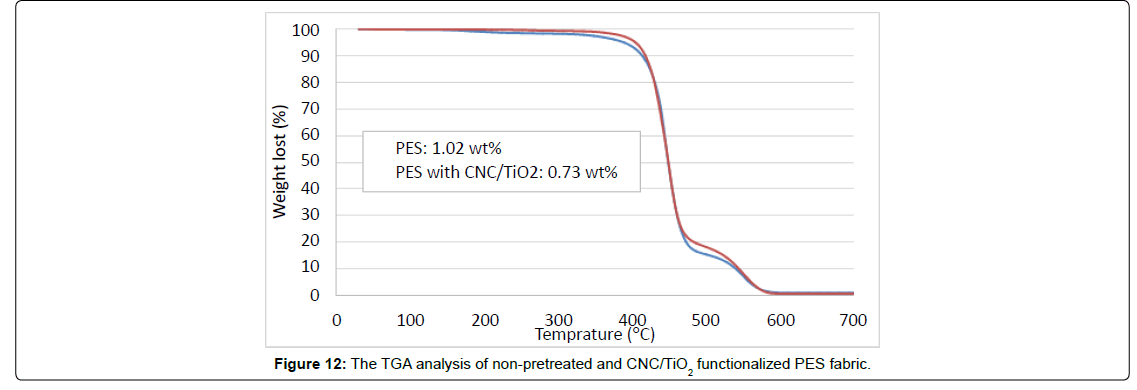

In addition to hydrolyzed samples, the suspension of CNC/TiO2 which was prepared with dispersion method was applied to a nonpretreated PES fabric. The Figure 12 presents one of the results out of three for the thermogravimetric analysis of non-pretreated PES fabric before and after functionalization with CNC/TiO2.

Normally, after the functionalization process, the weight of the textile substrate should increase as we add several products onto fabric. However, as it can be seen from Figure 12 that there is a decrease between non-treated (1.02 ± 0.004%) and functionalized PES fabrics (0.70 ± 0.09%). It was supposed that, the products which were applied during the weaving process were eliminated because of the padding and fixing (drying, curing) steps. In order to verify this phenomenon, a textile substrate was passed through the padding process (pressure: 2 Bar and the speed of the rollers: 7 rpm) using distilled water (without any chemical product). After the padding process, the sample was dried and cured at 105°C and at 150°C during 5 min, respectively. The water padded sample was characterized for thermogravimetric analysis and the weight of residue was 0.70 ± 0.06% relative to the initial fabric weight. These results proved that the weight of residue decreases from 1.02 ± 0.004% to 0.70 ± 0.06% after the padding and fixing processes by eliminating nonfixed products from fabric. When the weight of residue for water padded sample is compared to the CNC/TiO2 functionalized sample (Figure 12), it is clear that there are no TiO2 particles on the sample. As it is explained previously for SEM/EDX analysis (Figure 9), these results also confirmed the importance of the pretreatment for the functionalization of PES fabric.

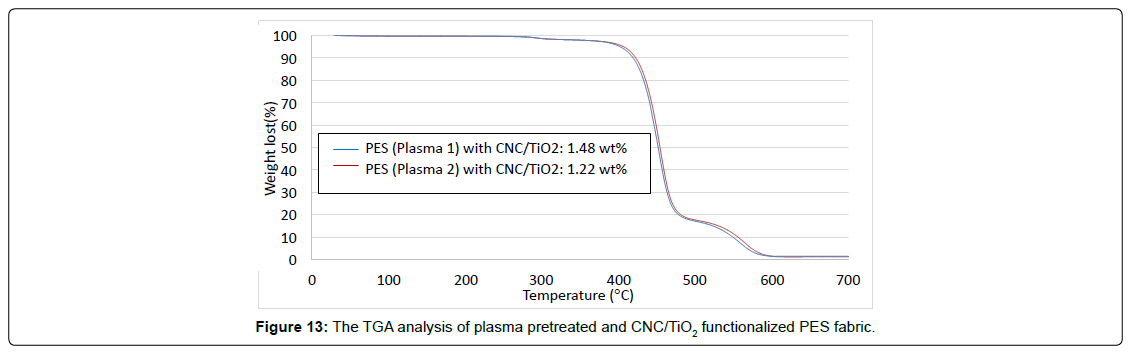

In order to understand the influence of the plasma treatment on the enhancement of the TiO2 to the PES fabric, plasma pretreated and functionalized samples were characterized with TGA [16]. The Figure 13 presents one of the results for the thermogravimetric analysis of plasma pretreated and functionalized PES fabrics.

It is clear from Figures 12 and 13 that there exists an increase in the weight of residue between PES fabric and plasma pretreated– functionalized fabrics. For the plasma 1 treated and functionalized sample, the weight lost was 1.44 ± 0.1% and the plasma 2 treated and functionalized sample, this value was 1.24 ± 0.1%. These results confirmed that, pretreatment with plasma has a positive influence on the binding of TiO2 as alkaline treatment. If the plasma treatments are compared using the treatment parameters (Table 1), it can be concluded that the retention of TiO2 increases by increasing treatment time and thickness. It may be supposed that when the treatment time and thickness increase two times, the added TiO2 quantity increases approximately two times. This supposition should be proved with different treatment times and thicknesses.

The photocatalytic activity of the treated samples will be tested by using a measuring unit at laboratory scale. By doing this, it can be decided if these concentrations are enough or not. If the concentration is insufficient, the concentration of TiO2 in CNC/TiO2 suspension can be increased and the padding process can be optimized (pressure and roller speed).

Conclusion

As presented during other previous study the first results gave satisfactory results for application of TiO2 and CNC on a synthetic fiber based textile substrate. The SEM/EDX analysis and TGA results showed that for the functionalization of polyester fabric with TiO2, it is needed to pretreat the sample either with alkaline hydrolysis or plasma treatment. These pretreatments enhance the adhesion of CNC/TiO2 on fabric. Both treatments gave satisfactory results and it can be chosen depending on the application and the opportunities. Although the suspensions of CNC/TiO2 were prepared with different methods (dispersion and sol-gel) for alkaline hydrolysis and plasma treatments, approximately same quantities were used for TiO2 (0.7 g for dispersion and 0.8 g for sol-gel method). Regarding to the percentage of residue weight from TGA, the results were in the same range for alkaline hydrolyzed functionalized sample and plasma 2 treated functionalized sample. The slightly highest results were obtained for plasma 1 treated functionalized sample. The results from plasma treatment showed that increasing treatment time and thickness have a positive influence on the binding of TiO2. Future studies look at studying with doped-TiO2 which can be realized by three processes, i.e. sol-gel, Physical Vapor Deposition (PVD) or ion implantation, in order to have a photocatalytic activity with visible light. The photocatalytic activity of the treated samples will be tested by using a measuring unit at laboratory scale for IAQ. By doing this, the parameters like needed TiO2 amount on textile surface and textile treatment (plasma, alkaline) can be defined in order to optimize the photocatalytic activity. In addition to these, the durability properties (washing, abrasion, TiO2 release) of developed depolluting textile will be evaluated.

Acknowledgment

This study is realized thanks to the Interreg V France-Wallonie-Vlaanderen program (TEXACOV Project of Portfolio GoToS3). Thus, the authors gratefully acknowledge the European Regional Development Fund (ERDF), the Walloon Region and West Vlaanderen Provincie for their financial support.

References

- Kaunelien V, Prasauskas T, Krugly E, Stasiulaitien I, Ciuzas D, et al. (2016) Indoor Air Quality in Low Energy Residential Buildings in Lithuania. Build Environ 108: 63-72.

- Langer S, Beko G, Bloom E, Widheden A, Ekberg L (2015) Indoor air quality in passive and conventional new houses in Sweden. Build Environ 93:92-100.

- Brown T, Dassonville C, Derbez M, Ramalho O, Kirchner S, et al. (2015) Relationships between socioeconomic and lifestyle factors and indoor air quality in French dwellings. Environmental Research 140: 385–396.

- Langer S, Ramalho O, Derbez M, Riberon J, Kirchner S, et al. (2016) Indoor environmental quality in French dwellings and building characteristics. Atmospheric Environment 128: 82-91.

- Tatibouet JM (1998) Plasma non thermique et traitement de l’air, Les composés organiques volatiles dans l'environnement ed Tec & Doc Lavoisier (Ecole des Mines de Nantes) 41-44.

- Turkyılmaz ŞŞ , Guy N, Ozacar M (2017) Photocatalytic efficiencies of Ni, Mn, Fe and Ag doped ZnO nanostructures synthesized by hydrothermal method: The synergistic/antagonistic effect between ZnO and metals. J Photochem Photobiol A Chem 341: 39-50.

- Radetic M (2013) Functionalization of textile materials with TiO2 nanoparticles. J Photochem Photobiol A Chem. 16: 62-76.

- Bozzi A, Yuranova T, Kiwi J (2005) Self-cleaning of wool-polyamide and polyester textiles by TiO2-rutile modification under daylight irradiation at ambient temperature. Journal of Photochemistry and Photobiology C: Photochemistry Reviews 172: 27-34.

- Morent R, De Geyter N, Verschuren J, De Clerck K, KiEkens P, et al. (2008) Non-thermal plasma treatment of textiles. Surf Coat Tech 202: 3427-3449.

- Yang L, Li J, Wang Z, Liu Z, Chen Q (2010) Calibration of amine density measurement on plasma grafting PET surface and its cell adsorption behavior. Surf Coat Tech 205: 345-348.

- Montazer M, Sadighi A (2006) Optimization of the hot alkali treatment of polyester/cotton fabric with sodium hydrosulfite. J Appl Polym Sci 100: 5049-5055.

- Heath L, Thielemans W (2010) Cellulose nanowhisker aerogels. Green Chemistry 12: 1448-1453.

- Hu L, Wang J, Zhang J, Zhang Q, Liu Z (2014) An N-doped anatase/rutile TiO2 hybrid from low-temperature direct nitridization: enhanced photoactivity under UV-/visible-light. RSC Adv 4: 420-427.

- Wanqing L, Changqing F, Xing Z, Qian Y, Shaofei P, et al. (2018) Cellulose nanocrystals obtained from office waste paper and their potential application in PET packing materials. Carbohydr Polym 181: 376-385.

- Ayoub H, Kassir M, Raad M, Bazzi H, Hijazi A (2017) Effect of Dye Structure on the Photodegradation Kinetic Using TiO2 Nanoparticles, J Material Sci Eng 5: 31-45.

- Gidik H, Almuhamed S, Dupont D, Derue L, Thielemans W, et al. (2018) Volatile Organic Compounds (VOCs) Treatment by a Functionalized Textile. J Fashion Technol Textile Eng S5.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi