Mini Review, J Nucl Ene Sci Power Generat Technol Vol: 12 Issue: 4

A Mini Review on Multi-Optimization for Hydrogen Production via Steam Methane Reforming

Ja-Ryoung Han*

KOGAS Research Institute, Korea Gas Corporation, 1248, Suin-ro, Sangnok-gu, Ansan, Gyeonggi-do 15328, South Korea

*Corresponding Author: Ja-Ryoung Han

KOGAS Research Institute, Korea Gas Corporation

1248, Suin-ro, Sangnok-gu, Ansan

Gyeonggi-do 15328, South Korea

E-mail: hanjaryoung@kogas.or.kr

Received date: 19 July, 2023, Manuscript No. JNPGT-23-107118;

Editor assigned date: 21 July, 2023, PreQC No. JNPGT-23-107118 (PQ);

Reviewed date: 7 August, 2023, QC No. JNPGT-23-107118;

Revised date: 14 August, 2023, Manuscript No. JNPGT-23-107118(R);

Published date: 21 August, 2023 DOI: 10.4172/2325-9809.1000346.

Citation: Han JR (2023) A Mini Review on Multi-Optimization for Hydrogen Production via Steam Methane Reforming. J Nucl Ene Sci Power Generat Technol 12:4.

Introduction

Hydrogen, being a sustainable and alternative energy carrier, has gathered significant attention due to its potential in addressing global energy challenges. It has led to the expansion of related industries and research studies. Among the various methods for hydrogen production, Steam Methane Reforming (SMR) stands out as one of the most promising approaches [1,2]. Therefore, extensive optimization research to enhance the efficiency, cost-effectiveness, and environmental performance of hydrogen production process using SMR is being conducted.

Especially, multi-objective optimization techniques provide a powerful framework for simultaneously optimizing multiple conflicting objectives, such as maximizing hydrogen production efficiency while minimizing CO2 emissions or reducing operating costs. By applying these optimization methods, researchers can explore various decision variables such as operating conditions or reactor configurations to identify the optimal solutions that achieve the desired trade-offs between different objectives [3-5].

In this mini-review, a concise summary of application of multiobjective optimization in hydrogen production process and SMR reactor design is provided. This review serves as a valuable resource for researchers and practitioners interested in the optimizing hydrogen process and SMR reactor design, offering insights and directions for further exploration in this field.

Literature review

Hydrogen production process

Various technologies are available for hydrogen production, with reforming being a common method. Typically, hydrogen is produced through the reforming process using hydrocarbon-based feed-stocks such as liquified petroleum gas, natural gas, or naphtha. Additionally, coal or biomass gasification has been employed as a primary process in the past. More recently, in line with the goal of reducing carbon emissions, attention has been given to plasma-based methods using renewable energy sources, which do not generate pollutants or can be combined with carbon dioxide reforming processes.

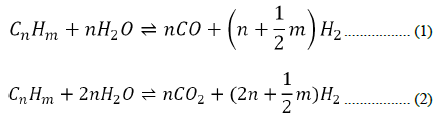

SMR is a widely adopted method for large-scale production and also a promising technology for small-scale production of hydrogen energy [6]. This process involves the catalytic conversion of methane and water vapor into hydrogen and carbon dioxide, as shown in reactions:

In the steam reforming step, the preheated hydrocarbon feedstock is mixed with steam and introduced into the SMR reactor containing catalysts, typically nickel-based. The presence of the catalyst and high temperature (usually ranging from 700℃ to 1000℃) promote the endothermic reforming reaction.

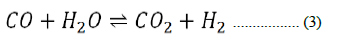

To further increase the production of the hydrogen and reduce the presence of carbon monoxide, the water-gas shift reaction is typically employed. This reaction converts carbon monoxide and water vapor into carbon dioxide and additional hydrogen as shown in reaction (3).

The resulting product gas mixture consists of hydrogen, carbon dioxide, carbon monoxide, and trace impurities. To enhance the purity of the produced hydrogen, a purification process is employed. This process eliminates impurities and contaminants, ensuring that the final hydrogen meets the required standards of purity.

Steam reforming reactor

The steam reforming reactor is a vital component in the production of hydrogen through the SMR process [7,8]. Operating under high temperature and pressured conditions, it facilitates the endothermic reforming reactions. The reactor can have various geometric configurations, including tubular reactor, packed-bed reactor, micro- reactor, membrane reactor, and catalytic plate reactor. It can be classified based on the position of the burners (top, bottom, side, terrace) [9]. Additionally, it can be classified by the flow direction of the reforming and combustion gases (counter-current, co-current), the structure of reaction tubes (singular, annular, finned), or the shape of the combustion furnace (cylindrical, cube). The SMR reactor typically consists of a cylindrical vessel constructed from high-temperature resistant materials, such as stainless steel or nickel alloys, which ensure durability under the operating conditions. The heat for the highly endothermic reactions is typically supplied by a furnace or external heating system.

The design and optimization of the steam reforming reactor are critical to ensure multiple variables such as efficient heat transfer, optimal catalytic reaction, and uniform temperature distribution [6]. Since the steam reforming is a crucial part in the production of hydrogen, the reactor’s design and operation play a significant role in achieving high hydrogen yields, process efficiency, and addressing environmental considerations for sustainable hydrogen production.

Overview of multi-objective optimization

Multi-Objective Optimization (MOO) is a powerful technique employed in engineering problems where multiple conflicting objectives need to be considered simultaneously. In contract to traditional single optimization approaches, MOO aims to identify a set of solutions that provide the best trade-offs among the competing objectives. These solutions, referred to as Pareto optimal solutions, collectively form a Pareto front or Pareto set, representing the range of optimal solutions in the objective space. The application of MOO is particularly beneficial in complex systems where decision-making involves trade-offs between multiple objectives with either competing or complementary relationships, as often encountered in many realworld engineering problems.

In order to identify the Pareto front, a variety of optimization algorithms and techniques are employed, such as genetic algorithms and evolutionary algorithms. In particular, within the researches of Computational Fluid Dynamics (CFD), MOO allows for the comprehensive exploration of wide range of design variables using surrogate models. This is a significant advantage of MOO in the CFD field, enabling to handle complex, high-dimensional problems [10]. Moreover, the integration of MOO in the CFD field facilitates the exploration of design spaces, leading to the discovery of innovative solutions and improved system performance. By considering multiple objectives simultaneously, MOO provides engineers and researchers with a more holistic approach to problem-solving, enabling the optimization of system performance under various operating conditions. Additionally, MOO aids in uncovering non-intuitive relationships and insights into the underlying physics of the fluid flow phenomena, enhancing our understanding and enabling betterinformed designs.

Application of multi-objective optimization in hydrogen production

In the context of hydrogen production processes and SMR reactor design, MOO techniques holds can play a crucial role in improving the efficiency, sustainability and economic viability of these systems. CFD has emerged as a powerful tool in investigating and improving reactor designs by simulating the complex fluid flow, heat transfer, and chemical reactions within the reactor [11,12].

Several prior studies have employed MOO in conjunction with CFD to optimize the design of various hydrogen production reactors, including auto-thermal reactor, membrane reactor and on-site SMR reactor [13]. Among these studies, the article titled “Multi-objective optimization of hydrogen production process and steam reforming reactor design” specifically focuses on the application of MOO to the hydrogen production process and SMR reactor design [4]. Notably, this work represents the pioneer effort in concurrently optimizing both the overall process efficiency and SMR reactor design except the previous parametric study [14].

The obtained Pareto optimal results demonstrate reactor size reductions ranging from 20.69% to 50.53% compared to a reference reactor, while the process efficiency varies from 105.00% to 86.66% compared to a reference process. These findings indicate that, despite the reduced reactor size, the overall process efficiency can still be improved. The implications of these findings are practical and can inform the design and operation of on-site hydrogen production systems.

Discussion

Challenges and future directions

The challenges and future directions of multi-objective optimization techniques in the field of hydrogen production system and steam reforming design encompass several key aspects that require attention and further exploration.

One of the key challenges lies in achieving the simultaneous optimization of multiple objectives, which often involve conflicting goals, For instance, maximizing process efficiency while minimizing reactor size or cost. The interplay between various variables, such as reaction kinetics, mass and heat transfer, and reactor design parameters, needs to be thoroughly understood to strike an optimal balance among these conflicting objectives. This calls for the development of advanced optimization algorithms and techniques capable of handling complex multi-objective problems.

Conclusion

Additionally, considering additional realistic constraints is an essential direction for future research in this field. In practical applications, hydrogen production systems and steam reforming reactors are subject to various constraints, such as equipment limitations, safety requirements, and environmental regulations. Incorporating these constraints into the optimization process ensures the practicality and feasibility of the proposed solutions. Future studies should focus on developing robust optimization frameworks that can account for these realistic constraints while finding optimal designs.

Lastly, the utilization of data-driven approaches, such as machine learning and surrogate modeling, can enhance the efficiency and effectiveness of multi-objective optimization. These techniques enable the exploration of large design spaces, provide valuable insights into the relationships between variables, and facilitate the identification of promising regions for further analysis. Incorporating data-driven approaches into the optimization process can accelerate the design cycle and aid in the discovery of optimal solutions.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi