Research Article, J Nucl Ene Sci Power Generat Technol Vol: 11 Issue: 6

Ecological Consequences of Elevated Producing Electricity

Pooja Singh1*, Prashant Kumar2 and Durgesh Wadhwa3

1Department of Physics, SGT University, Gurugram, Haryana, Tunsia, India

2Department of Electrical and Electronic Engineering, Teerthanker Mahaveer University, Uttar Pradesh, India

3Department of Electrical and Electronic Engineering, Sanskriti University, Mathura, Uttar Pradesh, India

*Corresponding Author: Pooja Singh, Department of Physics, SGT University, Gurugram, Haryana, Tunsia, India; E-mail: pooja_singh@sgtuniversity.org

Received date: 09 February, 2022, Manuscript No. JNPGT-22-47017; Editor assigned date: 11 February, 2022, PreQC No. JNPGT-22-47017 (PQ); Reviewed date: 25 February, 2022, QC No. JNPGT-22-47017; Revised date: 13 April 2022, Manuscript No. JNPGT-22-47017 (R); Published date: 02 May 2022, DOI: 10.4172/2325-9809.1000286

Citation: Pooja S, Prashant K, Durgesh W (2022) Ecological Consequences of Elevated Producing Electricity. J Nucl Ene Sci Power Generat Technol 11:6.

Abstract

In the modern era energy production from the renewable sources play a major role in country economic sector the evolution of electric power generating systems is examined, with a focus on plant efficiency. Efficiency improvements that are compatible with high plant dependability and low energy costs are widely known, but their impact on reducing total plant pollutants without the installation of extra environmental equipment is less well understood. Efficiency enhancement, as the only realistic instrument able of lowering CO2 emissions from relic fuel plants in the near term, has become a crucial idea for the selection of technology for new plants and upgrades of existing plants as CO2 emission control gains traction. Efficiency is particularly crucial for longer-term CO2 emission reduction options such as Carbon Capture and Sequestration (CCS); highly efficient underlying facilities are required to offset the energy penalty associated with CCS technology deployment. The timelines for the development, demonstration, and commercial ease of use of the different technologies are given special consideration. The creation and implementation of coal-based gasification technologies for power production are reviewed in this paper. The current state of gasification throughout the world is discussed, as well as the different process and technological choices. The use of gasification for power production is next discussed, along with the benefits and drawbacks of this method of coal use.

Keywords: CO2 emission; Electric power generation; Efficiency; Environment; Fossil fuels

Introduction

Coal is important to our globe, via its usage in delivering far cheap energy and also in constructing our society via its use in iron and steel. The globe absolutely requires coal is indeed coal the cheapest option for power generation in many areas, but it remained the sole feasible choice for key sectors. Coal even plays a major part in the development of renewable energy infrastructure and sustaining these fuels on the grid. It is important to the social development of hundreds of millions of people, especially in developing countries [1].

Energy generation have agreeable a major role in the modern era and if it is coming through the renewable energy recourses than is it well and good for the future prospective also. Diesel energy sources, sometimes called diesel electric channels, are buildings which thus create electricity by steaming coal. Zambia relies use power generation for basis points of its electricity, while Developing countries depend on power generation for a large portion of their gas. Asia, and from the other hand, consumes much more coal than most other nations. Iron provides electricity to the few who did not in fact own it, increasing living standard and decreasing poor in these places; yet, it also produces large quantities of different gases, worsening air durability and causing environmental [2].

Gasification, which involves converting This same conversion of fuels, waste, as well as detritus in to other highly flammable or fabrication gases with latter use does have power and can provide all these sustainable power and chemists. This manuscript offers an ideal overall idea of changes and developments, together with biogas divisions, biomasses heat transfer, naphtha substances, and fossil fuel, while also pyrolysis for generating electricity, metal processing, and oil petroleum products, with something like a strong emphasis on combustion for elaborate solar and wind. Gasification-based modern biomass PV system necessitates RD (Research and Development).

Slow cooked briquettes are so often utilized in power plants to generate energy owing to the coal reserves. Petroleum is first mashed into particles that also increases a contact surface but also allows it to burn more quickly. In muffle furnace combustors (PCC) solutions, ground coal is driven into something of a boiler's exhaust stream where that is burnt at high temperatures to create electricity that converts water-in ducts lined the water heater-in to one of steam. Many of rocket razors are used to feed slightly elevated water vapours into something of a machine. The turbine shaft spins at a high speed when the vapour pushes individual blades. A turbine, made up of tightly wound wire coils, is located on the surface of the driveshaft. When they should be rapidly twirled in what seems like a ferromagnetic material, they generate energy [3].

Following traveling from side to side the turbine, the vapour is generated and returned to the furnace to be heated once more. The energy produced is converted into the voltage spikes-up to 400,000 volts needed for cheap, transmission through power line networks. Whenever it draws nearer the end of expenditure, such as our houses, the energy is converted reduced to the safer 100-250 voltage systems utilized in the residential marketplace.

Efficiency improvementsClassic Portland cement concrete cogeneration design will ultimately improve, as well as new igniting methods will now be investigated. Those kind of allow forward for vitality to all be produced from little coal, resulting in fewer coal of been required to maintain the same level of energy decrease carbon output. This will be referred to as increasing the energy bacteria's cooling capacity. Om tee systems, which are classified as Supersonic flow, Ultra supercritical and Advanced Ultra supercritical, operate similarly to conventional sources but at higher pressures. Due to improved steam characteristics, critical boilers are more efficient than pressurized burning fuel. Instead of boil, superheated in severe machines reaches a supercritical state. Bigger altitudes but also mechanical loading are part of the improved power generating periods that also leads to higher efficiency and less coal use [4].

Integrated gasification combined cycle (IGCC)Petroleum really isn't burned initially in IGCC facilities, but moreover reacts with water but also vapour to produce a’syngas mainly composed of synthesis gas. After being cleaned of impurities, the syngas is burnt in propane generator energy and vapors for quite a coal fired cycle. A heat is produced it during gasification but also degasifications phases may also be used in the Rankin cycle or just for the wind distillation tower.

Circulating fluidized bedSteam is burned in a heated sleep of extract ant bits which have been set in vibration (fluidized) by engine cylinder blasted in below it through a line of outlets in inlet engine. First most common inlet combustors model nowadays is CFB. CFB operates at gas speeds sufficiently enough as to regulate a substantial proportion of minerals (4-10 m/s, 12-30 ft/s), which is then split out from combustion products transported redirected (recalculated) to the bottom reactor for natural carbon exhaustion and SO2 coagulant usage. As more than just a separating device, an externally heated cyclone is often employed near the furnace output.

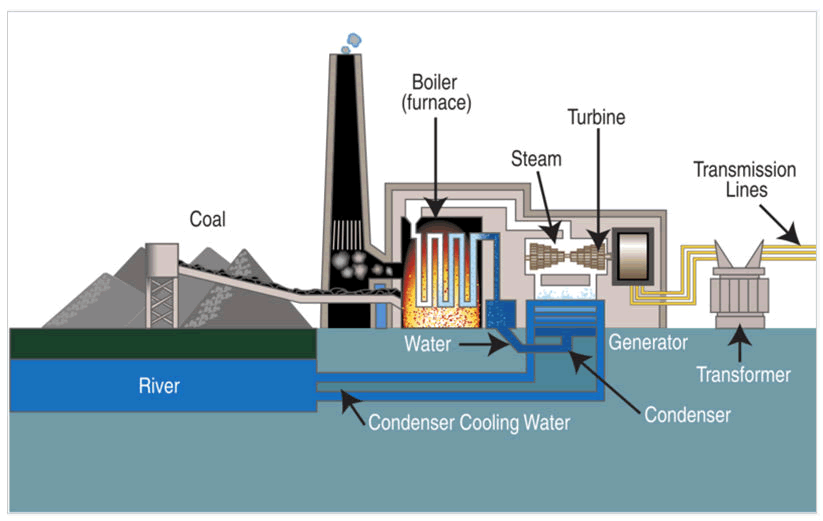

Through complement the cracked hydrocarbons; sandstone is pumped further into bubble column for SO2 reduction. This same sandstone is broken down into hydration of cement, some of which reacts with SO2 to create calcium sulfate. Blotchy oil, granite, fulvic acids, hydrated lime, and embers making up the bed in sustained performance. Because of its well-mixed architecture of said bed and the particularly long residence time of the fuel bed (due to high land filling in the CFB), effective detonation may be performed at wind chills as 843-899 degrees Celsius (1550-1650 degrees Fahrenheit). This same ideal condition bands for in-situ SO2 adsorption by calcium sulfate are found in this burner [4]. Figure 1 discloses the Process of a Coal Fired Power Plant to Convert Coal into Electricity.

Materials and Methods

In their case study suggested that the three forms of Feature lets And much is being used to investigate steam energy conversion vicious circle (IGCC) solutions using CO2 collection employing corporeal permeability, thermo chemical emission (CLC), but also proceed through the development operation (CLP) and renewable power. Path coefficients of important factors on mechanical behavior, which including sustainable development and environmental reliability, are investigated. Condensation to diesel fuel ratio compared (S/C) mostly in range of 0-20 point margin and breathable air to materials ratio compared (O/C) throughout the ranges of 70-105 cents are the common steps investigated in the heating unit. This same operation of the three capture methods described above is considered in terms of mass and material efficiency. An IGCC plant that does not collect biomass can be used as a benchmark for evaluating utilization. According to the results, this same CLC solution has quite 39.78 point margin power consumption, and that is 2.06% and 2.90 times higher than in the CLP and tangible diffusion approaches, respective [5].

Expert in their case study suggested that Estimates imply that the adoption of PHEVs may influence demand peaks, decrease reserve margins, and raise pricing. The kind of power production utilized to recharge the PHEVs and related emissions will vary with the area and the time of the recharge. The research findings Adopt sophisticated co-generation latest technology notably Produce creative but also olefin emission of CO2 separation, it may be extended to 23% of Europe's metrics for measuring significant GHG cut.

The mission's building of a new buyer simulation program or steam heaters is a key outcome. When opposed to older heater real world testing in Asia, common modelled apps is expected to cut this same time and budget of boiler evaluation by 60-75%. The above experimental software tool, which reduces computational burden and has been designed for, might very well potentially improve the effectiveness of said boiler achievement researcher and speed up the CO2 emissions with steam renewable power [6].

Team of expert in their case study suggested he evaluate the paths for ecological step up by the coal use sector for force making in Australia. In terms of funding, his results indicate that petroleum is a long term resource of concern since coal reserves are expected to endure for the next 500 years or more. But, his study shows that evaporation wounded of water in power production will reach 1000 Gl (gigalitres) per year, equal to a usage of half of the Australian residential population. As Australia is the second driest continent on earth, water use by power producers is a resource of urgent weight with respect to sustainable development. He also demonstrates that coal will continue to play a significant role in energy production in Australia and, therefore, there is a need to use innovative technologies that may reduce ecological effects [7].

Our study revealed that the production of energy with the help of coal is quite effective, coal is a major source of power generation in many field it is cost effective and affordable in the usage of the industry. Bituminous-It is a middling grade of coal with high heating potential. It is the nearly all frequently utilized kind of coal for power production in India.

Results and Discussion

There really are four main kinds of coal. Grade refers to stage in a long, natural process termed “coalification,” during which buried plant matter transforms into an increasingly denser, drier, more carbon-rich, and harder material. The four rankings are:

Anthracite: This same location of bitumen at its highest point. It's really pretty difficult, unyielding, mixed race matte petroleum with a good% age of hydro char and now a low quantity of volatility stuff, often made reference as the charcoal.

Bauxite is a kind of power generation that falls now between clinker and coals. Mostly in U.S.A, bauxite is used in generators but also scrap iron manufacturing but has a low heat capacity (Btu). After you first encounter coal, it seems cell shaded and smooth and sleek, but closer inspection reveals delicate, intermittent, sparkly but also matte seams [8]. Sub bituminous fuel is dark brown and has a poor (non-glossy) character (not shiny). Clinker coal is mainly used in electrical generation because of its fast pyrolysis characteristics. Lignite, often known as coals, is the dirtiest hydrocarbon with said low greenhouse gas content. Bauxite is mainly used in electrical generation because to its fast pyrolysis cost and low water holding capacity. Silt is still the forerunner of power generation. Silt is a soft, sloppy sustainably grown compound consisting of partly decomposed crop and other matter. Walnut produces physical chemical changes being exposed to pressurized conditions, resulting in carbon [8,9].

Partial gasification of coalIn what seems like a pressured liquid desiccant gas mixture, incomplete fiction pf coal delivers hydrocarbons for something like the Mazda's condiment turbocharger but also caster and combusting in what seems like a supercharged fixed-bed reactor (PFBC). In a Turbo diesel engine Carnot cycle, it thus generates carbon monoxide and for steam power plant or rather slightly elevated carbon monoxide and for Mpg. Their idea provides this same typical liquid desiccant advantages of reduced sensitivity to boost composition but also sculpture dioxide recovery via feedstock’s mostly in bed, as well as meeting the need of increasing average GT cooling capacity by using NG. At 870 1°C (1600 1°F), the vapours of the activated carbon smoking in the Card issuers are sanitized of particles and acids or rather directed to such GT, where even the provisional digester liquid is input. This same PFBC air flow has enough carbon to boil pure hydrocarbons mostly in GT's condiment turbocharger [10].

This same condiment spark plug will be of a high functionality that can be cool by PFBC tailpipe at 870°C rather than another usual expander exit air at 411°C avoiding frying. It is therefore a small recommended in order. The entire triple oval swirl cooker (MASB) from Mitsubishi addresses this same refrigerant issue: establishing covering of fuel flow from over back edge of covering ringed radial passageways throughout the turbocharger, resulting in Combustion of less than 9 parts per billion at 2% O2 that used waste heat main fuel. This same bacteria's utilization is predicted to be 48.2%. Commercial products titanium oxide channels also are used on alumina filters for electron clean up if the syngas and oxidized air wastewater of char pyrolysis are refrigerated to 538 1°C, and no potassium getters are needed. It thus dramatically reduces costs and improves allocation, but at the expense of a 46 point reduction in efficiency [4].

EnergyPower inlet and outlet estimates, the necessary building components for any existence assessment of conservatory gas emission, may be utilized to analyse the energy intend:

- Comparable Carbon Dioxide Emission (CO2e) are the quantity of conservatory gas emissions represented as carbon dioxide, taking into consideration overall warming effect of non-carbon dioxide greenhouse gases.

- Most power methods should be built-in in the CO2 section even if CO2 emission were minimal. Other contaminants with emission less than 100 mg/kWh are not included in the data and discussion.

Research used to construct CO2 statistics typically make up a distinct data set than the studies used to calculate additional emissions. Often LCA studies concentrate solely on CO2. This requires creating another data collection for additional emission. Power generation measurements should thus be utilized with warnings and limitations. No measurement identifies the optimal energy production method without the need for a supporting declaration of the fundamental value for evaluation. For example, a parameter such as generating capacity will effectively measure for interruption or washstand. A statistic such as value per unit of energy generated evaluates economic value according to standard accounting, finance, and cost-accounting assumption [11].

Green House Gas (GHG)Uncertainty for anthropogenic global warming and carbon dioxide (GHG) levels is now a driving force behind the push for alternative electricity. One such study looked at Carbon or Dioxide emissions Joints on various biomass and energy sources. Surprisingly, renewable are anticipated to emit much less CO2e with oil and coal; most projections of nuclear reactor emissions are similar in magnitude to those from integrating renewable. Even before carbon dioxide but instead flash memory (CCS) is added to energy and fuel installations, unfortunately, the perceived ease of renewable sources through regard of carbohydrates savings is significantly reduced. Going to add battery system to a solar and wind power reduces this proportionate benefit somewhat [12].

Emissions of nitrogen oxidesAs just a general, fossil fuels dependent on ignition have significantly greater amounts of Nitrogen oxides than it does someone who does not require combustion. The NOx generated during burning comes from two sources the oxidizing and volatilization of the nitrogen present in the firewood, and the high-temperature processes connecting ambient nitrogen and oxygen. The age band of NOx from ambient sources may be minimized or perhaps entirely avoided by conduct out the ignition under high-oxygen circumstances, so-called oxy-fuel combustion. Due to a major lack of LCAs, the amounts of NOx emissions reported here do not represent the concert of these systems [13].

Therefore, a very significant age of Iron will be used to power that new build plants. Moreover, through response to evolving EU regulations, such plants will have to have much enhanced global quality from existing units. Simultaneously, if the goal of distant emission levels was included in discussions, it will still be necessary to have available steam options of embedded N2o separation membranes suggest.

Everything just implies that its most important need is to ensure as method generally can obtain good efficiency and enhance proven reliability at a low cost of production. Its following are the most important needs for the next 5-10 years.

Enhanced fabrication methods for deformability and Women’s equality, as well as improving feed intake and ability to handle systems, are all part of the gas cleaning design. Fabrication of cogeneration compressor to ensure effective utilization of anion resources [14].

Auxiliary element improvements notably lower cost air separation units. Complimentary design and optimization studies, including full integration of CO2 capture.

Environmental impactsGreenhouse gases: Emission generates a variety of pollutants, including particulate emissions (Knox) and nitrogen oxide (Sox), as well as ultrafine particles. Those who also emit including carbonic acid (CO2) as well as Methane (CH4), many of which have been linked to climate changes. Electrical facilities necessitate devices to reduce the generation of those same dangerous compounds in order to help stop the leak.

Water pollutionBecause remove contaminants out power generation, freshwater are more often required; this process is known as coal laundry. In Asia, for example, this method is time consuming around was among the brine used for oil and gas industry. Because it eliminates around half of said starch content in the coal, this technique helps to reduce air pollution. As a result of the increased capacity factors, very little diethyl sulfide (SOx) and pollutants (CO2) are produced. Fish and also other marine organisms, as well as animals that rely upon several sources, could well be harmed because once steam turbines reduce the moisture content again from area. Drugs building up in waterways used by power plants, that if this water is pumped back into the earth, it may destroy the species that live within. Seepage from reactors as well as charcoal removal must be monitored and controlled. [15].

Conclusion

Currently, coal-fired Machined is just not the best system for energy companies since it is regarded to be more a costly coal and oil option than other. Because once steam technologies are adopted mostly in coming months, it is probable that slug’s solutions to nicest Emission and SO2 control and better boiler situations will be prioritized. Of better steam characteristics, there was an important opportunity for CFBC once again. Thus, from one long-term tactical perspective, IGCC is seen as the most viable route to distant energy generation. This goal can only be achieved if technology can provide an occurs early strong reputation for a lower capital cost system in the first place. To get this rank, certain RD criteria must be met.

Machined, was before acquisition, PC, which was flue gases take down, and identify the presence Desktop or CFBC are just the main stream thermoelectric generator systems with CO2 capture (CCS). Waste heat rinse for oxy-fuel plants must satisfy less rigorous deformation, natural gas processing, and adsorption criteria than it does for GT entry to the IGCC. Because of the powdered waste heat absorption requiring Removal of pollutants, oxy burning fuel in South Carolina and Ucla steam plants may be competitive with IGCC.

Emission collection, in leading to high plant costs, entails significant efficiency reductions; therefore it's critical that the bottom facility reliability have been as high as possible. Pricing analysis of contemporary steam distributed generators show typically, despite the somewhat higher starting pricing of higher throughput sites, Cost of energy and performance reductions drop as reliability improves among both plants with and without the CO2 capture.

The future scope of this paper is as a proportion of India's overall control output, coal is projected to drop from percent to percent during the next decade, according to India's innermost Electricity Authority. Excluding in absolute terms, coal usage will rise as India's total energy demand increases. Rising Production and Prices Over the years, the demand for coal has experienced a secular rise. For the year 2015-16, CIL had produced 536 million tons of coal, which has risen to 600 million tonnes of coal during FY20. Power demand has been rising, which speaks well for CIL's future prospects.

References

- Munawer ME (2018) Human health and environmental impacts of coal combustion and post-combustion wastes. J Sustain Min 17:87-96. [Crossref][Google Scholar][Pubmed]

- Oboirien BO, North BC, Obayopo SO, Odusote JK, Sadiku ER, et al. Analysis of clean coal technology in Nigeria for energy generation. Energy Strateg Rev 20: 64-70. [Crossref][Google Scholar][Pubmed]

- Grammelis P, Margaritis N, Karampinis E (2016) Solid fuel types for energy generation: Coal and fossil carbon-derivative solid fuels. InFuel flexible energy generation 29-58. [Crossref][Google Scholar][Pubmed]

- Wu XD, Xia XH, Chen GQ, Wu XF, Chen B, et al. (2016) Embodied energy analysis for coal-based power generation system-highlighting the role of indirect energy cost. Appl Energy 184: 936-950. [Crossref][Google Scholar][Pubmed]

- Zhu L, Jiang P, Fan J (2015) Comparison of carbon capture IGCC with chemical-looping combustion and with calcium-looping process driven by coal for power generation. Chem Eng Res Des 104: 110-124. [Crossref][Google Scholar][Pubmed]

- Hadley SW, Tsvetkova AA (2009) Potential impacts of plug-in hybrid electric vehicles on regional power generation. Elec J 22: 56-68. [Crossref][Google Scholar Scholar][Pubmed]

- Diniz Da Costa JC, Prasad P, Pagan RJ (2004) Modern environmental improvement pathways for the coal power generation industry in Australia. Process Saf Environ Prot 82: 191-199. [Crossref][Google Scholar][Pubmed]

- Lacchini C, Dos Santos JCV (2013) Photovoltaic energy generation in Brazil-Cost analysis using coal-fired power plants as comparison. Renew Energy 52: 183-189. [Crossref][Google Scholar][Pubmed]

- Othman MR, Zakaria R, Fernando WJN (2009) Strategic planning on carbon capture from coal fired plants in Malaysia and Indonesia: A review Ener Policy 52: 183-189. [Crossref][Google Scholar] [Pubmed]

- Lokmic Z, Mitchell GM (2008) Engineering the microcirculation. Tissue Eng Part B Rev 14: 87-103. [Crossref][Google Scholar][Pubmed]

- Agaton CB (2018) Use coal or invest in renewables: A real options analysis of energy investments in the Philippines. Renewables Wind Water Sol [Crossref][Google Scholar][Pubmed]

- Khor CS, Lalchand G (2014) A review on sustainable power generation in Malaysia to 2030: Historical perspective, current assessment, and future strategies. Renew Sustain Energy Rev 29:952-960. [Crossref][Google Scholar] [Pubmed]

- Mondal MA, Rosegrant M, Ringler C, Pradesha A, Valmonte Santos R, et al. (2018) The Philippines energy future and low-carbon development strategies. Ener Mar 15;147:142-54. [Crossref][Google Scholar] [Pubmed]

- Lin B, Li J (2015) Does China’s energy development plan affect energy conservation? Empirical evidence from coal-fired power generation. Emerg Mark Finance Trade. 51: 798-811. [Crossref][Google Scholar][Pubmed]

- Wang J, Wang R, Zhu Y, Li J (2018) Life cycle assessment and environmental cost accounting of coal-fired power generation in China. Ener Policy 115: 374-384. [Crossref][Google Scholar][Pubmed]

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi