Research Article, J Nucl Ene Sci Power Generat Technol Vol: 11 Issue: 2

Electromagnetic Calculation Double-Rotor Hydro Generator

Kunelbayev Murat1*, Mekebayev Nurbapa 2, Iskakova Makpal3,Mukhametov Yeldos4, Diyarova Lyazat5

1Department of Nuclear Energy Science, Al Farabi Kazakh National University, Almaty, Kazakhstan

2Department of Nuclear Energy Science, Kazakh National Women's Teacher Training University, Almaty, Kazakhstan

3Department of Nuclear Energy Science, Abai Kazakh National Pedagogical University, Almaty, Kazakhstan

4Department of Nuclear Energy Science, L N Gumilyov Eurasian National University, Almaty, Kazakhstan

5Department of Physico-Mathematical Science and Technology, Yessenov University, Aktau, Kazakhstan

*Corresponding Author :Kunelbayev Murat

Department of Nuclear Energy Science, Al Farabi Kazakh National University, Almaty, Kazakhstan

E-mail: murat7508@yandex.kz

Received date: 25 February, 2022, Manuscript No. JNPGT-22-45206;

Editor assigned date: 01 March, 2022, PreQC No. JNPGT-22-45206 (PQ);

Reviewed date: 14 March, 2022, QC No. JNPGT-22-45206;

Revised date: 21 March, 2022, Manuscript No. JNPGT-22-45206 (R);

Published date: 24 March, 2022, DOI: 10.4172/2325-9809.1000263

Citation: Kunelbayev Murat, Mekebayev Nurbapa, Iskakova Makpal, Mukhametov Yeldos, Diyarova Lyazat (2022) Electromagnetic Calculation Double-Rotor Hydro Generator. J Nucl Ene Sci Power Generat Technol 11:2.

Abstract

This article discusses experimental calculations of a disk generator on permanent magnets for a micro-hydroelectric power station with a capacity of 1,5 KW. The dynamic operation mode of the disk generator was studied. Research and calculations were carried out by computer simulation using the program "Ansoft Maxwell". During the simulation, the characteristics of the induced EMF in the stator winding of a disk generator were studied. The study of electromagnetic processes by modeling a disk generator shows that the creation of a hydro generator for a micro hydroelectric power plant gives a doubling of the speed of the hydro generator, due

to a doubling of the frequency, which reduces the number of pole pairs, the number of windings, and also reduces the internal diameter of the stator core. With the help of these indicators, the geometric and mass dimensions of the hydro generator are reduced, as well as the cost of the installation itself is reduced.

Keywords: Water, Electromagnetic wave, Disc generator, Micro hydro power plant

Introduction

In this article are considered, experimental calculations of the disk generator with constant magnets of low power for micro hydroelectric power stations where a basic element is axial crarop the generator of a field for reception of energy of water. The purpose of analytical model, working out of the car which will facilitate timely design and complete support of electromechanical model of system of reception of energy [1].

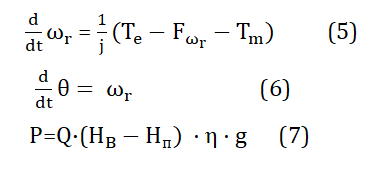

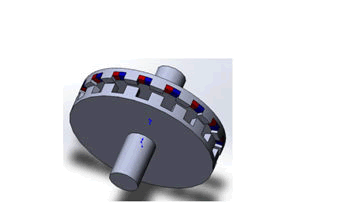

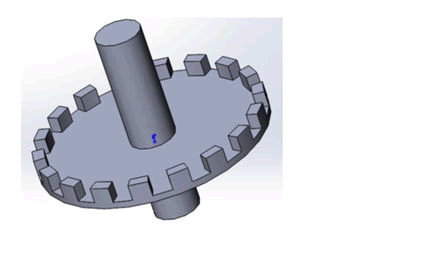

Calculation of an electromagnetic field has the big importance because calculation of a constant of the rotating moment, an electromotive power for this purpose is required. To receive magnetic field decisions an analytical method, for constant magnets of the disk generator, were present were in the literature of the car of a radial current, rectilinear, and a configuration of an axial stream. However, for the decision of axial cars of a current [8, 9, 10] accuracy of the decision for a finding of cars of width of a magnet or a ring craropa is used. Axial cars form the disk generator with bearing magnets which make an axial stream and a disk craropa, containing phase airings. In this basic design there is a possibility of many variations, including to adjoining. Two parties Torrid. And it is a lot of magnets. Magnets are opposite put on the disk generator which are arranged in such a manner that the North Pole on one rotor faces the South Pole on other, leading to an axial magnetic field in such a manner that the collar craropa demands for facing magnets N-N. To analyse a magnetic field in the axial car, the basic computing works are applied in the reference. To the magnetic field analysis in axial cars, calculations are applied, based in works in sources. However, the analytical model presented in sources assumes presence iron craropa and that intensity of a field on borders (craropa and a rotor). Thus, the equations developed. Are changed by superposition application, that is the field is defined by addition of fields. As a result magnets on each party of the rotor, operating individually and reactions an anchor field. Though superposition is not applied, if its saturation of an anchor of the car usually do not work in a saturation condition (Figures 1-3)[2-6].

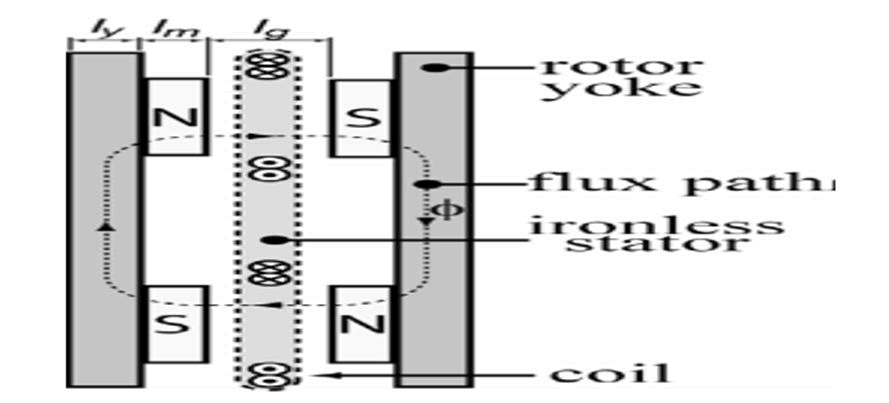

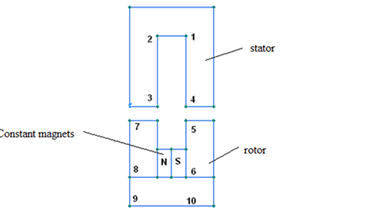

Figure 1:Construction of dual-rotor axial PM generator (looking inward radially).

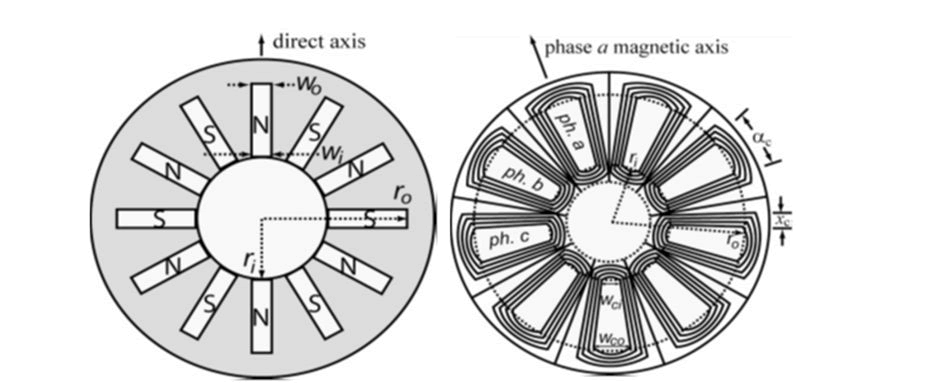

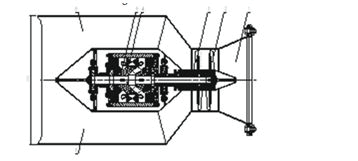

Figure 2:Construction of dual-rotor axial PM generator: rotor (left) and stator (right).

Model of the proposed micro-hydro power plant

In the offered scheme микÑ?о hydroelectric power stations system of development of energy which makes 3 kW of capacity which can be used for rural electrification. The water-wheel is one of most prominent aspects of a power supply system [7].

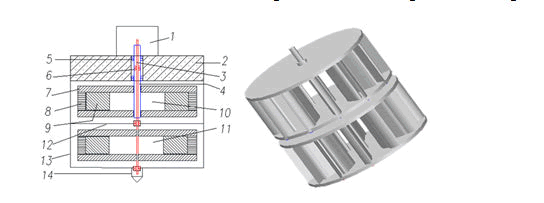

Figure 3:The circuit diagrammed double-rotor micro hydroelectric power station and model double-rotor turbines.

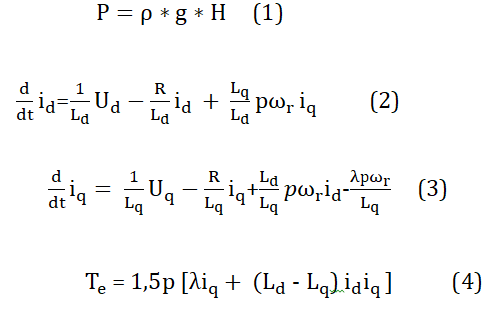

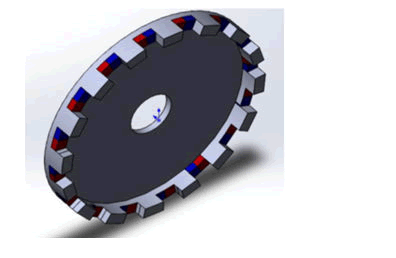

Installation as follows works. Installation consists of two independent vertical driving wheels 10 and 11, located one over another. Each driving wheel has the shaft of rotation 3 and 4. On external a floor to a shaft 4 with the help radials the basic bearing 5 the tank - a float 2 fastens [8]. It is not placed double-rotor the generator 1. In the middle of a hollow external shaft 4 it is established radials - the basic bearing 6 on which internal ring takes place an internal integral shaft 3 bottom driving wheels. Each driving wheel consists from: the top and bottom rim 7, blades 9 and before a wing 8. Two turbines are divided among themselves by a dividing plane 12 and protected by a metal grid 13. At installation immersing on water installation work is carried out as follows: the water stream arrives on turbines and they start to rotate every which way at the expense of various installations of blades and before a wing [9]. The bottom driving wheel it is connected to a rotor of the generator by means of an internal shaft and rotates clockwise. The top driving wheel it is connected with stator the generator by means of an external shaft and rotates counter-clockwise. Thus rotation of a rotor and stator is carried out rather each other in the opposite sides that provides increase in frequency of crossing with a magnetic field of an electric winding of the hydro generator. Such technical decision allows to avoid presence of the animator for increase in frequency of rotation of a rotor as in the classical generator. Moreover there is a possibility to simplify a design such double-rotor the hydro generator and to lower it mass dimensions the sizes [10-14]. Hydraulic capacity is accessible from the hydraulic turbine, can be expressed as follows. The electric part of model of the car is described system of the equations, with a rotor:

In system the equation following designations are accepted:

- inductive of stator on axes d and q;

R - active interfaces stator;

current projections stator on an axis d and q;

,- pressure projections stator on an axis d and q;

- angular frequency of rotation of a rotor;

- a magnetic stream of constant magnets;

P - number of pairs poles;

- electromagnetic the moment.

The mechanical part of model is described

Where j - the total moment of inertia of a rotor and loading;

F -factor friction;

- the resistance moment.

Capacity of micro hydroelectric power station is defined under the formula:

Where Ð - capacity, kw;

Q - the water expense through the turbine, a km/s cube;

geometrical height from top to bottom, m;

- hydraulic losses in which pipelines;

- factor useful (0,5... 0,7);

– a accelerations of free falling (9,8m/s2).

At carrying out of researches and workings out in area waterpower physical and mathematical models as natural experiments are not always possible both on technical, and for economic reasons are widely used. The mathematical model describes real object only with some degree of approach (detailed elaboration). Thus the model kind depends as by nature investigated object, and on research problems, the technique of modeling necessary for accuracy of the description of object. Division of mathematical modeling into three principal views is standard: analytical, imitating and combined. Prominent feature of analytical modeling is the description of processes of functioning of elements of modeled system in the form of some parities −differential, Integra-differential, certainly or logic conditions. The analytical model can be investigated following methods. Analytical (thus the purpose is reception of various dependences for required characteristics in a general view); numerical (in this case the purpose is reception of numerical results at the certain initial data, and the decision is not in a general view); Qualitative (the decision in an explicit form is absent, but it is possible to estimate some properties of the decision) (Figures 4 and 5) [15].

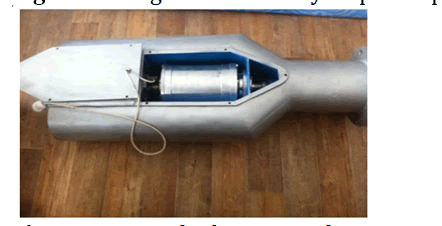

Figure 4: A design of the disk generator.

The generator consists from stator and a rotor. Stator contains packages from electro technical steel. Stator the disk generator it is carried out a traditional grooving design. The internal surface of the core craropa a traditional design contains grooves 1, with alternating teeth. A teeth provides reduction of not magnetic backlash between stator and a rotor.

Figure 5:A design of the disk generator.

Principle of action of the generator the following. At a food of a winding of excitation by a direct current she creates a magnetic stream which becomes isolated on a following way: a tooth crown stator, an air backlash, a pole of a rotor, northern magnet, a southern magnet, a pole of a rotor, an air backlash, a tooth crown stator and dredging stator (Figures 6 and 7) [16].

Figure 6:Rotor

Figure 7:Generator segment.

The most important characteristic is the synchronous hydro generator rotor speed, which allows you to get the necessary speed standard values [17]. As can be seen from the formula 1, an increase in hydro-generator rotor speed n reduces the number of pole pairs p.

p = 60 â?? f / n (8)

To increase the hydro-generator rotor speed must increase flow or pressure hydraulic flow in the supply of the micro hydro generator. However, increasing the hydraulic parameters of micro hydro generator is not always possible and expedient. In the case of hydro-generator, as seen, requires fewer pairs of poles than the conventional hydroelectric generators because at a certain value of rotor speed can be obtained by hydro-generator stator speed in the opposite direction with the same values (Figures 8 and 9) [18]. In this case the rotation of the rotor and stator of hydraulic, as already indicated above, is carried out with respect to each other in the opposite side. This leads to an increase in the frequency of crossing the magnetic field of electric generator windings. This principle of doubling the speed will hydro generator. Produced analysis and study of electromagnetic calculation hydro generator including a selection of the main dimensions of the stator and rotor hydro generator show that the number of winding turns , the inner diameter of the stator core hydro generator D_(0) is almost two times less than traditional hydro generator . These results can be achieved only in the case of the hydroelectric principle, which generally leads to a reduction in the geometric and mass-dimensions hydro generator [19].

where- - the number of windings hydro generator; p = 1 - number of pole pairs hydro generator;=60, the number of effective-conductors in the slot hydro generator;=3, the number of slots hydro generator; а1 =1, the number of parallel branches in the stator winding hydro generator; -inner diameter of the stator core hydro generator;= 122 mm -the outer diameter of the stator core hydro generator;the number of windings of traditional hydro-generator; p = 2, the number of pole pairs of the traditional hydro-generator; -99-effective amount of conductors in the groove of traditional hydro-generator; q_1 = 3, the number-hydro generator traditional slots; -inner diameter of the stator core of traditional hydro-generator; = 175mm,-the outer diameter of the stator core of traditional hydro-generator.

Installation as follows works. Installation consists of two independent vertical driving wheels 10 and 11, located one over another. Each driving wheel has the shaft of rotation 3 and 4. On external a floor to a shaft 4 with the help radials the basic bearing 5 the tank a float 2 fastens. It is not placed double rotor the generator 1. In the middle of a hollow external shaft 4 it is established radials the basic bearing 6 on which internal ring takes place an internal integral shaft 3 bottom driving wheels. Each driving wheel consists from: the top and bottom rim 7, blades 9 and before a wing 8. Two turbines are divided among themselves by a dividing plane 12 and protected by a metal grid 13. At installation immersing on water installation work is carried out as follows: the water stream arrives on turbines and they start to rotate every which way at the expense of various installations of blades and before a wing. The bottom driving wheel it is connected to a rotor of the generator by means of an internal shaft and rotates clockwise. The top driving wheel it is connected with stator the generator by means of an external shaft and rotates counter-clockwise. Thus rotation of a rotor and stator is carried out rather each other in the opposite sides that provides increase in frequency of crossing with a magnetic field of an electric winding of the hydro generator. Such technical decision allows to avoid presence of the animator for increase in frequency of rotation of a rotor as in the classical generator. Moreover there is a possibility to simplify a design such double-rotor the hydro generator and to lower it mass dimensions the sizes. Works installation follows. Initially, a single stream of water on the pressure pipe supplied to the supply chute turbine chamber 1. The flow around the turbine chamber around the perimeter, is directed at a certain angle on the blades of the first turbine wheel 2 and rotate it to one side. After the turbine impeller 2 more hydraulic flow at a predetermined angle is directed to the blades of the second turbine wheel 3 which rotates in the opposite direction by reversing the structure of the blade of the turbine impeller 3. Moreover, the turbine 2 and 3 are arranged in succession in a single feed pipe. The turbine 2 and the turbine 3 are connected respectively to the rotor and the stator of the generator via a shaft, wherein the shaft is located inside a turbine shaft another turbine. Thus, the turbine converts the hydraulic energy of water flow into rotational energy of shaft generator (rotor) 4 and 5 (the stator). Wherein rotation of the rotor and stator is carried out with respect to each other in opposite that provides an increase in the frequency of the magnetic field crossing winding electricity hydro generator. After passing through the turbine exhaust stream flows through the suction tube 6.

Figure 8:Diagram of micro hydropower plants with rotary hydro generator.

Figure 9:Micro hydropower plant.

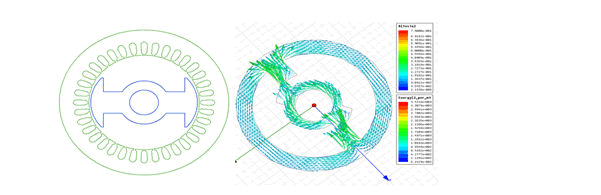

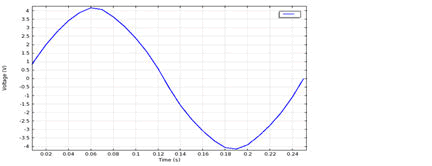

Analysis and study of the peculiarities of electromagnetic calculation disk generator in static mode does not allow to evaluate the work make full disk generator. This regard, studies have been conducted dynamic mode disk generator. Studies and calculations were carried out by computer simulation using the program «Ansoft Maxwell». During the simulation studied the characteristics induced EMF in the stator winding disk generator. On Fig.8.shows a fragment of the moment and the magnetic induction field lines at time t = 0.2sec (Figures 10 and 11).

Figure 10:Unit of magnetic induction and field lines at time t=0.2sec.

Figure 11: Voltage waveform disk generator.

Conclusion

Thus, in the first proposed new scheme for micro hydro disk generator with new technical solution and its structure. The analysis and study of electromagnetic processes by modeling disk generator shows that the creation of hydro-generator for micro hydro bir gives doubling speed hydro-generator, which allows to reduce the number of pole pairs, the number of windings, as well as to reduce the inner diameter of the stator core. This generally leads to a reduction of geometric and mass-dimensions of hydro-generator and as a result reduce the cost of micro hydro. In addition to these calculations, the computer simulation shows a complete dynamic stability of hydro-generator, which is characterized by forms of voltage and the induced emf. As a result of calculations the greatest influence on power indicators of the generator renders: width of a groove and size of an air backlash. From drawing 8 it is visible that at increase in number of grooves at a pole, the factor of dispersion of a pole that is an effective indicator for electric cars decreases. From this it follows that with reduction the width of a groove, increases its number of grooves on magnet of wires stator, the number of grooves thereby increases by one pole.

References

- Proca AB, Keyhani A, El-Antably A, Lu W, Dai M, et al. (2003) Analytical model for permanent magnet motors with surface mounted magnets. IEEE 18: 386-391.

- Rosu M, Arkkio A, Jokinen T, Mantere J, Westerlund J (1999) Prediction of airgap magnetic field distribution in large output power permanent magnet synchronous motor.

- Jung SY, Chun JS, Jung HK (2001) Performance evaluation of slotless permanent magnet linear synchronous motor energized by partially excited primary current. IEEE trans mag 37: 3757-3761.

- Virtic P, Stumberger B (2007) Analytical analysis of magnetic field and force calculation in a slotless-type permanent magnet linear synchronous machine; verification with numerical analysis. IEEE Int Electric Machines Drives Conf 2: 963-968.

- Furlani EP (1994) Computing the field in permanent-magnet axial-field motors. IEEE Trans Mag 30: 3660-3663.

- Bumby JR, Martin R, Mueller MA, Spooner E, Brown NL, et al. (2004) Electromagnetic design of axial-flux permanent magnet machines. IEE Proceedings-Electric Power Appl 151:151-160.

- Chan TF, Lai LL (2007) An axial-flux permanent-magnet synchronous generator for a direct-coupled wind-turbine system. IEEE Trans Energ Conversion 22: 86-94.

- Zhang YJ, Ho SL, Wong HC, Xie GD (1999) Analytical prediction of armature-reaction field in disc-type permanent magnet generators. IEEE Trans Energy Conv 14: 1385-1390.

- Chan TF, Xie S, Lai LL (2007) Computation of no-load and armature reaction fields of an axial-flux permanent-magnet synchronous generator. IEEE 1: 1-6.

- Gieras JF, Wang RJ, Kamper MJ (2008) Axial flux permanent magnet brushless machines. Springer Science & Business Media.

- Patterson D, Spee R (1995) The design and development of an axial flux permanent magnet brushless DC motor for wheel drive in a solar powered vehicle. IEEE 31: 1054-1061.

- Brown N, Haydock L, Bumby JR (2002) Foresight vehicle: A toroidal, axial flux generator for hybrid IC engine/battery electric vehicle applications. SAE Technical Paper.

- Spooner E, Chalmers BJ (1992)'TORUS': a slotless, toroidal-stator, permanent-magnet generator. IEE 139: 497-506.

- Huang S, Aydin M, Lipo TA (2001) TORUS concept machines: pre-prototyping design assessment for two major topologies. IEEE 3: 1619-1625.

- Kessinger R, Robinson S (1997) SEMA-based permanent magnet electric motors for high torque, high performance. Naval Symposium Electric Machines 151-155.

- Venikov VA, Venikov GA (1984) The similarity and modelling theory.− Ð?: the Higher school 439.

- Councils VY, Jakovlev SA (1999) Modelling of systems−Ð?: the Higher school 271.

- Simankov VS, Zangiev TT (2001) System the analysis at the decision of structural problems of alternative power / Institute of modern technologies and economy. – Krasnodar 151.

- AA Samara (1989) Mathematical modelling: Methods, descriptions and researches of difficult systems / under the editorship of. Ð?: the Science 271.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi