Research Article, J Nucl Ene Sci Power Generat Technol Vol: 14 Issue: 1

Feasibility Study of the Hydride Fuels (UZrH and UThZrH) in the VVER-1000 Core

S. Bagheri1*, F. Faghihi2, A. A. Bahrami2 and M. A. Mozafari1

1Department of Nuclear Engineering, Nuclear Science and Technology Research Institute (NSTRI), Tehran, Iran

2Department of Nuclear Engineering, School of Mechanical Engineering, Shiraz University, 1936-16548, Shiraz, Iran

*Corresponding Author: S. Bagheri

Department of Nuclear Engineering, Nuclear Science and Technology Research Institute (NSTRI), Tehran, Iran

E-mail:samiabagheri@gmail.com

Received date: 29 October, 2023, Manuscript No. JNPGT-23-118735;

Editor assigned date: 31 October, 2023, PreQC No. JNPGT-23-118735 (PQ);

Reviewed date: 14 Novemeber, 2023, QC No. JNPGT-23-118735;

Revised date: 17 January, 2025, Manuscript No. JNPGT-23-118735 (R);

Published date: 24 January, 2025, DOI: 10.4172/2325-9809.1000434

Citation: Bagheri S, Faghihi F, Bahrami AA, Mozafari MA (2025) Feasibility Study of the Hydride Fuels (UZrH and UThZrH) in the VVER-1000 Core. J Nucl Ene Sci Power Generat Technol 14:1.

Abstract

This article contains keywords on the hydride fuel as a new candidate to achieved higher power density in the current LWRs. More power density and lower operational temperature core are the major motivations to use hydride fuel instead of the current oxide fuel in the LWRs. In the current research, we have studied selected hydride fuels for the VVER-1000 core. A pitch optimization of the core delayed neutron fraction and prompt neutron lifetime; reactivity coefficients (fuel, moderator, and void) in the VVER-1000 core are investigated. Moreover, calculations for the fuel burn up and radionuclide inventory are carried out after one year of operational time. It is shown that the fuel cycle and discharge burn up are increased with hydride fuels.

The results showed that typical hydride fuel has useful properties such as higher excess reactivity, less initial U loading, and less Pu production. However, because of some disadvantages like positive moderator temperature coefficient and higher 135Xe and 149Sm build-up, more study is needed to use hydride fuel as an alternative fuel in LWRs.

Keywords: Hydride fuel; Fuel inventory; Power density; Reactivity feedbacks; Pitch optimization; VVER-1000

Introduction

Hydride fuel, including U-ZrH1.6 (45w/o U, and the other types which are described herein), are proposed as one candidate for the generation III+ LWRs, and this type of fuel was examined in TRIGA reactor [1]. Solid hydride fuel (and/or annular pins) can be replaced with the ordinary UO2 fuel, of the current LWRs, to upgrade those and to achieve lower operational temperature core [2].

Many studies were carried out on the hydride fuels in charge of overall project management, neutronics, fuel performance, economics, and material compatibility analysis; also in the thermal-hydraulics, safety, chemical compatibility studies, and finally rod vibrations.

Hydride fuel contains features so that we briefly mentioned and highlighted those and explained its advantages/disadvantages regarding the current oxide fuels. In the incoming sections, we briefly explain its features in LWRs [3]. After reviewing its advantages and/or progress, we focus on the main objective of this article i.e. assessment of the feasibility of improving the performance of VVER cores using hydride fuels (U-ZrH and UThZrH mixed with ZrB2 as Integral Fuel Burnable Absorber), instead of the commonly used oxide pins. Specifically, we examined two types of hydride fuel for the VVER type reactor which their details are addressed in the incoming section. As an important key, we have examined pitch calculations of the hexagonal FA to obtain the under-moderated core, and then the average core discharge burn up in the first operational cycle, for a typical VVER-1000 is calculated. Moreover, the reactivity feedbacks of the mentioned fuels are obtained [4].

The hydride fuel and its advantages/disadvantages

The nominal theoretical density of U-ZrH1.6 fuel at room temperature is 8.256 g/cm3 and the maximum practical U weight percent is 45%. This makes the atomic density of uranium in UZrH1.6 molecule about 40% of that in UO2 fuel. The advantages and disadvantages of hydride fuel as well as its properties against current ordinary oxide fuels are briefly reviewed in the following sections [5].

The temperature profile in the hydride fuel rods: To avoid hydrogen release, the design limits set-point for hydride core must be at lower average core temperatures. For instance, in the high power TRIGA core, the fuel temperature is about 750â?? at steady-state and 1050â?? under transients. These temperatures are significantly lower than the maximum permissible operating temperatures of UO2 fuel. Based on many studies, hydride fuel uses Liquid Metal (LM) as gap material rather than He gap used in the oxide fuel rod which has hot pressure of 90 MPa. The operational temperature in the centre of fuel is near 560â?? and 680â?? for LM and He (as the gap materials), respectively which is much less than UO2 fuel. Also, hydride fuel radial decreasing of temperature across the fuel meat is different than oxide fuel. The low fuel temperature prevents hydrogen loss in the core. Less core operational temperature can be considered as a safety key in comparison with current reactors including UO2 pins and this feature is considered as an advantage of the hydride fuel [6].

Fission gas release: Fission gas release in the hydride fuel and also its clad chemical compatibility is under investigation. The feasibility of using liquid metal bonding for LWR UO2 fuel improves the heat transfer from the fuel to the clad and thus reduces the peak fuel temperature, delays the onset of fission gas release, avoids Pellet Clad Interaction (PCI), and prevents Zr clad secondary hydrating due to cladding failure.

Swelling: In the hydride fuels, fission-product swelling may be worse with comparison to ordinary UO2 fuels. The thermal expansion properties of hydride fuels that affect clad deformation and the limit on the clad strain. Although the swelling rate of hydride fuel is expected to be more pronounced than that of oxide fuel, the liquidmetal bonding can accommodate swelling without straining the clad and without impairing the gap thermal conductance. Considering the liquid metal gap instead of the helium gap causes relocation by cracking to occur less than UO2. This effect is very important in metallurgy phenomena of solid fuel and homogeneity of thermal conductivity and causes benefit [7].

Power density: The concentration of hydrogen in the hydride pin is comparable to that of hydrogen in the water of LWR cores. The hydrogen needed for neutron moderation within the fuel volume permits the attainment of the optimal neutron spectrum while using smaller core water volume. This feature may enable the core to be designed to have optimal moderation in terms of the attainable more discharge burn up and to have a higher power density than a LWR core that uses oxide fuel.

Positive reactivity coefficients: As a disadvantage of the hydride fuel, we mention here that U-ZrH1.6 fuelled PWR cores were found to have a positive coolant temperature coefficient of reactivity at the Beginning of Cycle (BOC). Three ways are proposed (and examined) to offset this disadvantages, and to make negative reactivity feedbacks: (i) Replacement of some of ZrH1.6 with ThH2, (ii) Use of Er-167 or Integral Fuel Burnable Absorber (IFBA) as a burnable poison mixed in the hydride fuel, and (iii) Using plutonium as a fissile material instead of enriched uranium.

The BOC prompt (Doppler) reactivity feedback (due to fuel temperature increase) is more negative when using UZrH1.6 fuel than when using UO2 fuel due to a unique feature of hydride fuel (i.e., spectrum hardening owing to fuel hydrogen temperature increase). This prompt spectrum hardening effect is superimposed on enhances the Doppler Effect. However, the EOC prompt reactivity feedback is not as positive as in the BOC feedback because of the build-up of 239Pu. We come back to this feature in the research part of the current article for specifically a VVER-1000 core [8].

Thermal conductivity: Hydride fuel thermal conductivity is much greater than that of UO2 fuels (5-6 times greater). Although operational hydride fuel temperatures are significantly lower than the maximum permissible operating temperatures of UO2 fuel, the thermal conductivity of hydride fuel is ~5 times higher than that of oxide fuel. Consequently, U-ZrH1.6 fuel can safely operate at linear heat rates that even exceed those of commercial LWR. The LOCA also limits the attainable power of oxide fuelled cores but not that of hydride fuelled cores. This is due to the high thermal conductivity of the hydride fuel yielding lower initial fuel temperatures from stored energy redistribution and lower temperature increase over time from decay heat due to the higher volumetric heat capacity of hydride fuels [9].

Materials and Methods

VVER-1000 Reactor description and core modelling

The reference VVER core is defined as Boushehr Nuclear Power Plant (BNPP), and its selected design parameters that may be used in the current study are summarized in Table 1 [3]. BNPP is a typical VVER-1000 reactor with a nominal power of 3000 MWt (1000 MWe), and its core consists of 163 fuel assemblies arranged in the hexagonal lattice with a lattice pitch of 23.6 cm [10]. Each FA contains 311 fuel rods, 18 guiding channels for control rods and/or Burnable Absorber Rods (BAR); a central channel all arranged in a triangular lattice with a lattice pitch of 1.275 cm. The fuel rods are UO2 pellets including a central hole with zircaloy-4 cladding. Some important specifications of the core which are used in this study are listed in Table 1, which are taken from the final safety assessment report of BNPP (Atomic Energy Organization of Iran, 2007) [11]. 163 FAs with average enrichments of 1.6%, 2.4%, and 3.62% are arranged in a hexagonal array in the reactor core (Figure 1). Due to the core symmetry, it is enough to investigate the desired parameters for 1/6 region of the core (60-degree symmetry. However, we simulate the whole core model to obtain the exact values of desired parameters such as keff. All of the calculations have been performed with MCNPX2.6 code.

| Parameter | Value | |

|---|---|---|

| Core | Reference core pressure (MPa) | 15.7 |

| Nominal thermal power (MWt) | 3000 | |

| Inlet coolant flow rate (m3/h) | 84,800 | |

| Coolant temperature at the core inlet (K) | 564.15 | |

| FA geometry | Hexagonal | |

| FA pitch (mm) | 236 | |

| Fuel assembly | Number of fuel rods in a FA | 311 |

| Number of guide tubes | 18 | |

| Number of measuring tube | 1 | |

| Number of central tubes | 1 | |

| Fuel rod pitch (mm) | 12.75 | |

| Fuel rod | Hole diameter in the fuel pellet (mm) | 1.5 |

| Fuel pellet outside diameter (mm) | 7.57 | |

| Cladding inner diameter (mm) | 7.73 | |

| Cladding outer diameter (mm) | 9.1 | |

| Fuel pellet material | UO2 | |

| Cladding material | Alloy Zr+1% Nb | |

| Fuel pellet density (g/cm3) | 10.4-10.7 | |

| Fuel enrichment (%) | 1.6, 2.4, 3.62 | |

Table 1: The selected VVER-1000 reactor specifications (Atomic Energy Organization of Iran, 2007)

Figure 1: Arrangement of various FA types in the core and its 1/6 symmetry with a numbering scheme.

All of the simulations including pitch optimization and burn up calculations have been performed in the BOC, and Hot Zero Power (HZP) or Cold Zero Power (CZP) if necessary. Average coolant and fuel temperatures as well as boric acid concentrations at CZP, HZP, and Hot Full Power (HFP) are given in Table 2 [12]. In our simulation, in the HFP and also BOC, xenon, and other poisons concentrations reach their steady level but fuel is approximately considered to be fresh. Also, xenon free is considered at the HZP and BOC, and fuel is still assumed to be fresh. In the CZP, all reactor components are assumed at room temperature, xenon free, and fresh fuel. All of the cores were assumed without boric acid concentration to obtain the maximum excess reactivity for each model.

| Parameter | CZP | HZP | HFP |

|---|---|---|---|

| Average moderator temperature (â??) | 20 | 280 | 304.5 |

| Average fuel temperature (â??) | 20 | 280 | 789 |

| Boric acid concentration (g/kg-H2O) | 8.2 | 7.33 | 6.64 |

Table 2: Some properties of BNPP in BOC of the first cycle at three stages.

The fuel rod outer clad diameter, D, and the lattice pitch-todiameter ratio, P/D is considered for optimization. Additional considered parameters include the uranium enrichment level 12.5% for hydride fuel, and the coolant pressure drop across the vertical axis of the core is 30 psi [13].

Figure 2 shows the configuration of different fuel assemblies in the reference VVER-1000 core as well as one fuel rod cell as mentioned in Table 1. Here, we consider 5 types of fuel loading to the BNPP reactor as listed in Table 3. UO2 average fuel is the average enrichment of fuel used in the reference core that is simply calculated as average enrichment of the total fuel mass in the reference core. The enrichment of the 235U in two fuel types UZrH-3.75 and UThZrH-6 has been calculated such that the keff value for both cases is close to the keff value of the average UO2 fuel. Finally, the enrichment of UZrH-12.5 and UThZrH-12.5 fuel types has been selected from the references [14].

Figure 2: Configuration of different fuel assemblies in the reference VVER-1000 core.

| Fuel type | 235U enrichment (%) |

|---|---|

| UO2 (Ref. core) | 1.6, 2.4, 3.62 |

| UO2 average | 2.44 |

| UZrH-3.75 | 3.75 |

| UZrH-12.5 | 12.5 |

| UThZrH-6 | 6 |

| UThZrH-12.5 | 12.5 |

Table 3: Different fuel types considered in this work.

Since the goal of this paper is the neutronic investigation of replacement of these fuel types in the VVER-1000 reactor core, we limit the calculations to this reactor geometry including fuel pellet, gap, and cladding sizes. The following assumptions have been considered:

- The central hole for all cases is the same as the actual fuel rod hole which is filled with He gas.

- The fuel meat diameter is identical for all cases (7.57 mm).

- The gap between fuel and cladding is filled with He gas for BNPP average core, but for the other 4 fuel types, it is assumed to be filled with liquid metal as the references.

- The thickness of cladding is identical for all cases (0.685 mm).

- The dimension of FAs, as well as the core size, is fixed and the number of rods and their arrangement is the same as the actual core.

Since the goal of this paper is the comparison of using different fuel types in the VVER-1000 reactor, the burnable poison rods are kept in all fuel types. This is another work to determine which burnable poison material is appropriate for each fuel type [15].

Results and Discussion

Feasibility study of the VVER-1000 operation with hydride fuel

Pitch optimization of the core: Calculation of the optimum moderator-to-fuel ratio to determine the fuel pitch is among the important tasks in the neutronic design of a reactor core. The analytical method for calculating this parameter which uses the thermal utilization factor and resonance escape probability with consideration of the self-shielding and shadow effects is very complex and usually has considerable errors. As a brief description, to increase excess reactivity and decrease fuel loading and core size, it is necessary to determine the moderator to-fuel ratio and fuel pitch so that the fission neutrons which enter the moderator from the fuel, be able to avoid the main absorption resonances (i.e. 6.67, 21 and 37eV) before colliding with fuel material. Therefore, the optimum moderator-to-fuel ratio is determined where the result of multiplying the thermal utilization factor by resonance escape probability has the highest value. Fuel diameter from a neutronic point of view also should have the minimum self-shielding effect leading to neutron economy increment [16].

One of the important parameters of the core is the moderator-to-fuel ratio because by increasing the quantity of moderator in the core, neutron absorption in the moderator increases and causes a reduction in the thermal utilization factor. On the other hand, having an insufficient moderator in the core causes an increase in slowing downtime and results in a greater loss of neutrons by resonance absorption. In examining the multiplication factor as a function of moderator-to-fuel ratio due to competition between the thermal utilization factor and resonance escape probability, there is an optimum point from which the increase on the moderator-to-fuel ratio causes a decrease of the multiplication factor due to the dominance of the decreasing thermal utilization factor. Furthermore, the reduction of the moderator-to-fuel ratio from this point causes a reduction of the multiplication factor due to the dominance of increased resonance absorption in the fuel [17].

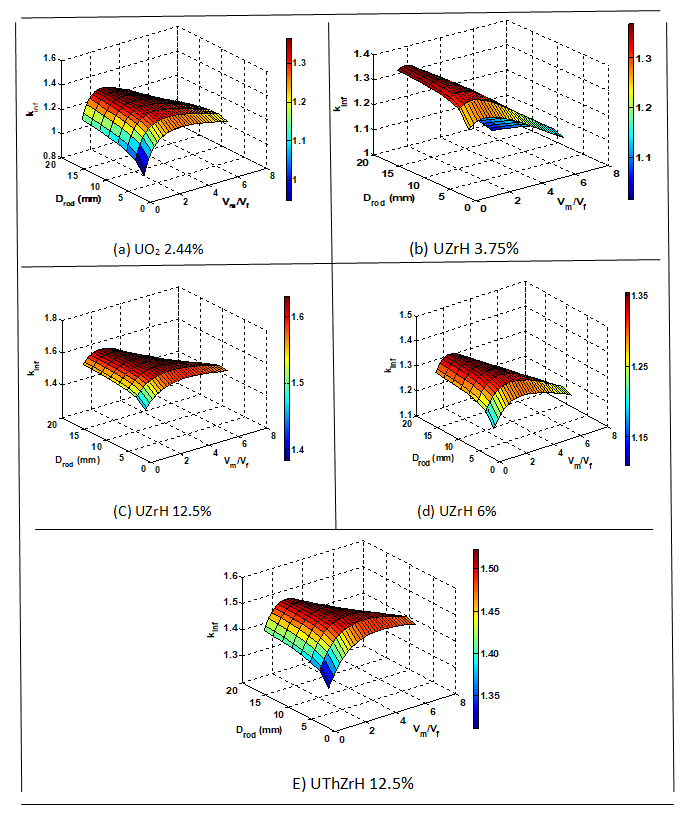

The calculations have been performed for each fuel case to find the appropriate pitch of the fuel rods. In this calculation, the infinite core is assumed and infinite multiplication factor value (kinf) is obtained as a function of Drod and Vm/Vf ratio (Figure 3). The range of changes for these parameters is 3

Figure 3: Infinite multiplication factor as a function of moderatorto- fuel ratio and different fuel rod diameters. <17>

The calculations have been performed again regarding these assumptions by considering a possible change for pitch value inside the FA geometry [18]. In the other words, we assume that all dimensions of the core, FAs, and fuel rods as well as their arrangement is the same as the actual core and only the pitch of fuel rods can be varied between the permissible values (i.e. 10.1 to 13.1 mm). This interval is 2 × Rco (fuel rod cladding outer radius) up to maximum pitch which is obtained such that the circumferential fuel rods in a FA are coincident with the FA boundary. The values beyond this interval are not practical. The results are shown in Figure 4 for all 5 fuel types. The pitch values of maximum kinf are listed in Table 4 for each fuel type. Note that all of these values are close to the reference core value representing that for this core size and configuration, the suitable pitch value is approximately identical.

Figure 4: Infinite multiplication factor as a function of the pitch in the CZP condition for all fuel types.

| Fuel type | Pitch (mm) |

|---|---|

| UO2 (Ref. core) | 12.75 (FSAR) |

| UO2 2.44% | 12.5 |

| UZrH 3.75% | 12.8 |

| UZrH 12.5% | 12.65 |

| UThZrH 6% | 12.65 |

| UThZrH 12.5% | 12.65 |

Table 4: Pitch values of maximum kinf calculated by MCNPX.

Delayed and prompt neutron fraction: The exact determination of the value of the effective delayed neutron fraction (βeff) is one of the main requirements in reactor physics. Here, βeff and prompt neutron lifetime are calculated by MCNPX2.6. We use the so-called prompt method for the calculation of βeff [19]. βeff was calculated by using the following formula βeff=1-(kp/k) which, kp is the prompt multiplication factor and k, is the total multiplication factor. The results have been presented in Table 5.

| Fuel | Delayed neutron fraction (pcm) | Prompt neutron lifetime (s) |

| UO2 2.44% | 676.197 | 2.81E-05 |

| UZrH 3.75% | 656.212 | 4.71E-05 |

| UZrH 12.5% | 660.341 | 1.94E-05 |

| UThZrH 6.0% | 674.145 | 2.72E-05 |

| UThZrH 12.5% | 665.071 | 1.68E-05 |

Table 5: Results of delayed neutron fraction and prompt neutron lifetime calculations.

Fuel temperature coefficient: The fuel temperature coefficient of reactivity is an important parameter in the evaluation of transients in light water reactors which is defined as:

Where k and Tf are the multiplication factor and fuel temperature, respectively.

The fuel temperature effect of a lattice is often calculated by performing pin-cell calculations of the infinite multiplication factor at different fuel temperatures. The question arises whether this fuel temperature coefficient of reactivity is a suitable measure for the fuel temperature effect of the lattice when it is situated in a reactor core.

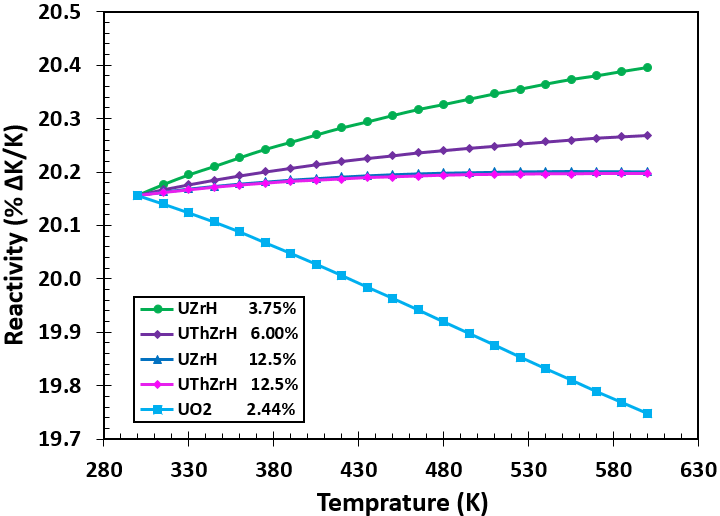

The reactivity coefficient of fuel temperature has been calculated for five proposed fuel types. Here, it is assumed that only the fuel temperature varies and keff value is calculated using WIMS-D5 by varying the fuel temperature from 293 K to 1097 K (Figure 5). Note that for better comparison, the curves are sketched from a common point in this Figure 5. As seen, 4 types of proposed fuels have a more negative temperature coefficient in comparison with UO2 average fuel.

Figure 5: Reactivity coefficient of fuel temperature of different fuel types.

Moderator temperature coefficient: The Moderator Temperature Coefficient (MTC) of reactivity in water-moderated reactors is an important operational parameter connected with safety considerations. The MTC is defined as the change of reactivity per degree change of the core-averaged moderator temperature. As a rule, a reactor core is designed such that the MTC has a negative value. This ensures that negative reactivity feedback will be provided in the event of power excursion. However, the value of MTC should not be too negative because there exist certain off-normal sequences, in particular some cool-down accidents in PWRs, which are aggravated by a large negative MTC [20]. Therefore, in power PWRs, limits are established on how negative MTC may become during the fuel cycle, and surveillance tests are performed during the fuel cycle to determine if the MTC value complies with the specified limits. Boron dilution is generally used as a standard experimental method in such types of measurements. To calculate the water temperature coefficient of reactivity, it is assumed that only the water temperature changes from 293 K to 593 K for all fuel types. The results have been shown in Figure 6.

Figure 6: Moderator Temperature Coefficient (MTC) of reactivity for different fuel types.

As seen in this Figure, the slope of all curves except the average UO2 is positive. This is due to the effect of hydrogen inside the fuel material. The gradient of UZrH-3.75 fuel is more than other fuel types because of the further H/235U ratio in this fuel.

Three approaches that can turn the positive Coolant Temperature Coefficient of reactivity (CTC) of U–ZrH1.6 fueled PWR cores to be negative were identified for the D–P design range offering peak power:

- Use of erbium burnable poison instead of the boron diluted poison.

- Replacement of some of the ZrH1.6 by ThH2. As seen in the Figure, this results in fewer slopes for the UThZrH fuel type.

- Use of Pu rather than enriched uranium as the primary fissile material.

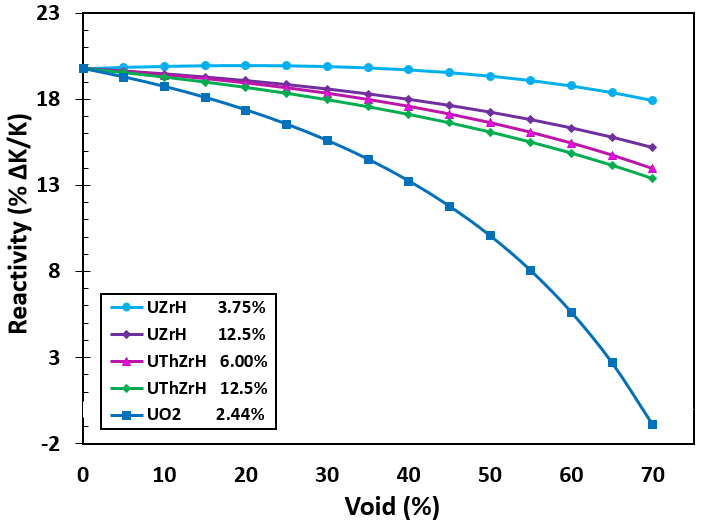

Void coefficient: The void coefficient of reactivity is the rate of change in the reactivity of a water reactor system resulting from a formation of steam bubbles as the power level and temperature increase. Although in the PWR reactors, the bubble formation is not significant, it must be considered especially for accidents including the vapor generation. To calculate the reactivity coefficient for change of void, the water void is assumed from 0% void content (corresponding to 0.7121 g/cm3 density) to 70% void content (corresponding to 0.2459 g/cm3 density). Figure 7 shows the calculation results for proposed fuel types. Here, UZrH-3.75 fuel is the worst case because of the least negative slope compared to the other fuel types.

Figure 7: Void coefficient of reactivity for different fuel types.

Burn-up calculations: The burn-up calculations have been performed for all proposed fuel types to study fuel behavior in a fuel cycle. It is assumed that all fuel types were irradiated for 365 Effective Full Power Days (EFPDs). Note that although a FA remains in the core for 3 years duration, it was irradiated for 1 year in full power mode. In the following sections, the results of burnup calculations will be described.

Effective multiplication factor: Figure 8 shows the result of the burn-up calculation for the keff parameter of proposed fuel types. Based on this figure, UZrH-12.5% and UThZrH-12.5% fuels have the most keff value because of their higher enrichment in comparison to the other fuel types. Moreover, the minimum keff value refers to UZrH-3.75% fuel. It must be mentioned here that the gradient of all curves is approximately equal except for the UZrH-3.75% fuel that has a sharper slope because of excess hydrogen inventory in the fuel.

Figure 8: Keff variation versus time.

135Xe and 149Sm build-up: The materials that capture neutrons without leading to any subsequent fission are called neutron poisons. They can be either naturally occurring elements or produced in the core due to fission, e.g. Boron and Cadmium are naturally occurring elements whereas 135Xe and 149Sm are the fission products. Although neutron absorption cross-sections for several fission products have a significant effect on reactivity, 135Xe and 149Sm have the most considerable impact on reactor design and operation due to their relatively high fission yield and absorption cross-sections for thermal neutrons. As they remove neutrons from the reactor, they have an impact on the thermal utilization factor and thus reactivity. As a result, the presence of these isotopes decreases the reactivity and hence the operating life of the reactor. The results of 135Xe and 149Sm production in the proposed fuels have been shown in Figure 9 and 10. As expected, the production of these poisons is further in UZrH-12.5% and UThZrH-12.5% fuels because of their higher enrichments.

Figure 9: 135Xe inventory variation versus time.

Figure 10: 149Sm inventory variation versus time.

Heavy isotopes production: Major heavy isotopes produced in all fuel types have been presented in Figure 11. The trend of the curves is the same. In addition to 232Th that was present as a part of fuel material, 233U is being produced in thorium fuels. It is worth mentioning that approximately 82% of 235U inventory has been spent in the UZrH-3.75 fuel, while in the UO2 average fuel this value is around 51%. Moreover, in UZrH-12.5 and UThZrH-12.5 fuels, the consumed amount of 235U is less than 36% in both cases.

Figure 11: Major heavy isotopes production in different fuel types.

From the curves of Figure 10, it is evident that different fuel types have various burn up values in a one-year full power cycle. The most burn up value is about 38 GWd/MTU for both hydride fuels. The thorium fuels undergo a burn up of about 23.9 GWd/MTU while the average UO2 fuel has 14.93 GWd/MTU burn up. The change in mass of major fuel isotopes is presented in Table 6 for all fuel types. The most spent amount of 235U isotope is related to UThZrH 12.5% with 789 Kg. Moreover, the 239Pu isotope inventory is produced less than UO2 fuel.

| Fuel type | Δm U-235 | Δm U-238 | Δm Th-232 | U-236 | Pu-239 | Pu-240 | Pu-241 | Pu-242 | U-233 |

| UO2 2.44% | 531 | 400 | - | 92.2 | 215 | 34.9 | 11.4 | 0.9 | - |

| UZrH 3.75% | 439 | 236 | - | 70.1 | 77.2 | 26.2 | 7.03 | 1.14 | - |

| UZrH 12.5% | 515 | 136 | - | 92.4 | 72.5 | 7.54 | 1.56 | 0.06 | - |

| UThZrH 6.0% | 709 | 274 | 174 | 119 | 108 | 29.7 | 9.83 | 1.25 | 99.8 |

| UThZrH 12.5% | 789 | 200 | 100 | 143 | 108 | 15.8 | 4.57 | 0.27 | 75.1 |

Table 6: Consumption and production of major fuel isotopes for all fuel types (all units are in Kg).

Conclusion

A review of the studies in the field of hydride fuel application in LWRs has been performed. Several features of this fuel type have been investigated and compared with present fuels in various areas including neutronics, fuel performance, economics, material compatibility analysis, thermal-hydraulics, safety, chemical compatibility studies, and finally rod vibrations. Hydride fuels potentially offer significant benefits over current oxide fuels for LWR operation with minimum change in core design and components. Uranium-zirconium hydrides have successfully operated at higher temperatures and linear heat generation rates than required for operation in LWRs. The use of hydride fuels in today’s research reactors continues due to a long track record of successful operation and positive experience. The use of liquid metal gap filler in the hydride fuels effectively compensates for the relatively large volumetric swelling of hydride fuel and eliminates many of the pellet cladding interaction problems. The result is a high power density fuel that operates at a much lower temperature than that of oxide type.

Based on this review, replacement of some of the Zr hydride by Th hydride can, actually, somewhat increase the attainable discharge burnup. High thermal conductivity of the hydride fuel yields lower initial fuel temperatures from stored energy redistribution and lower temperature increase over time from decay heat due to the higher volumetric heat capacity of hydride fuels. Many of the positive features and specific aspects of hydride fuels that have been discussed here portray them as a strong candidate for an advanced fuel in future power-generation applications. Although a large amount of knowledge is available based on the current and historical data on properties and behavior of hydride fuels, due to the complexity and nature of the nuclear fuel applications, much further work is required.

The feasibility study of hydride fuel (UZrH and UThZrH) application in a typical VVER-1000 reactor is performed and some features of its deployment in the VVER-1000 reactor core are investigated and analyzed. After the pitch calculation of the proposed fuel types, it is concluded that the appropriate value of fuel rod pitch in all cases is close to the current pitch value in the reference core. The reactivity coefficient of fuel temperature has been calculated for the proposed fuel types. It is determined that all the fuel types have a more negative temperature coefficient in comparison with UO2 average fuel. Although this is an important advantage for hydride fuels, the moderator temperature coefficient of reactivity of all fuel types is positive due to the presence of hydrogen inside the fuel material. Moreover, all fuel types have a less negative void coefficient of reactivity with respect to average UO2 fuel.

From the results of burn up calculations, the fuel type UZrH-12.5 has the most keff value due to its higher enrichment in comparison to the other fuel types. Moreover, 135Xe and 149Sm production in the proposed fuel types is higher than the reference average core except for UZrH-3.75 that has the least poison production. This is an advantage for this fuel. The most burn up value is about 38 GWd/MTU for both hydride fuels. The thorium fuels undergo a burn up of about 23.9 GWd/MTU while the average UO2 fuel has 14.93 GWd/MTU burn up. As a general outcome, these results demonstrate that the proposed fuels having higher power density and burn up values, produce lower 239Pu mass, and therefore are more suitable from the point of reprocessing issue. It is concluded that the application of proposed hydride fuels in the VVER-1000 reactor is feasible and the works may be continued in the other areas to accomplish the overall project in this field.

References

- Ashoub N, Saleh HG (2000) Neutronic evaluation of two proposed fuel lattice pitches for ET-RR-1 reactor. Ann Nucl Energy 27: 553-561.

- Atomic Energy Organization of Iran, A (2007) Final Safety Analysis Report (FSAR) for BNPP Accident Analysis.

- Bagheri S, Faghihi F, Nematollahi MR, Behzadinejad B (2016) Assessment of thermal hydraulics parameters of the VVER-1000 during transient conditions. Int J Hydrogen Energy 41: 7103-7111.

- De Kruijf WJ, Janssen AJ (1993) On the definition of the fuel temperature coefficient of reactivity for pin-cell calculations on an infinite lattice. Ann Nucl Energy 20: 639-648.

- Faghihi F, Fadaie AH, Sayareh R (2007) Reactivity coefficients simulation of the Iranian VVER-1000 nuclear reactor using WIMS and CITATION codes. Prog Nucl Energy 49: 68-78.

- Faghihi F, Mirvakili SM, Safaei S, Bagheri S (2016) Neutronics and sub-channel thermal-hydraulics analysis of the Iranian VVER-1000 fuel bundle. Prog Nucl Energy 87: 39-46.

- Faghihi F, Mirvakili SM (2011) Shut-down margin study for the next generation VVER-1000 reactor including 13×13 hexagonal annular assemblies. Ann Nucl Energy 38: 2533-2540.

- Ganda F (2008) Physics of hydride fueled PWR. University of California, Berkeley.

- Ganda F, Greenspan E (2009) Neutronic analysis of hydride fueled PWR cores. Nucl Eng Des 239: 1425-1441.

- Greenspan E (2006) use of solid hydride fuel for improved long-life LWR core designs. Univ. of California (United States).

- Greenspan E, Fratoni M, Ganda F, Ginex F, Olander D, et al. (2009) Hydride fuel for LWRs-project overview. Nucl Eng Des 239: 1374-1405.

- Greenspan E, Shayer Z, Olander D, Moalem M, Todreas N, et al. (2003) Preliminary assessment of possibilities for improving the performance of LWRs using hydride fuel. Trans Am Nucl Soc 381-382.

- Fundamentals D (1993) Nuclear physics and reactor theory.

- Hussain A, Xinrong C (2009) Core optimization simulation for a pressurized water reactor. Inf Technol J 8: 250-255.

- Iorgulis C, Ciocanescu M, Preda M, Mladin M (1998) Neutronic calculations regarding the new LEU 6 x 6 fuel bundle for 14 MW TRIGA-SSR, in order to increase the reactor power up to 21 MW.

- Lewis EE (2008) Fundamentals of nuclear reactor physics. Elsevier.

- Malen JA, Todreas NE, Hejzlar P, Ferroni P, Bergles A (2009) Thermal hydraulic design of a hydride-fueled inverted PWR core. Nucl Eng Des 239: 1471-1480.

- Malen JA, Todreas NE, Romano A (2004) Thermal hydraulic design of hydride fueled PWR cores.

- Michalek S, Stevo S, Farkas G, Hascik J, Slugen V, et al. Determination of the effective delayed neutron fraction for training reactor VR-1. Prog Nucl Energy 52: 735-742.

- Mourtzanos K, Housiadas C, Antonopoulos-Domis M (2001) Calculation of the moderator temperature coefficient of reactivity for water moderated reactors. Ann Nucl Energy 28: 1773-1782.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi