Research Article, J Nucl Ene Sci Power Generat Technol Vol: 12 Issue: 6

Investigation of Suitable Alloys for X-Ray/Gamma Radiation Shielding

KV Sathish1*, R Munirathnam2, KN Sridhar1, HC Manjunatha1, N Sowmya1 and L Seenappa1

1Department of Physics, Government First Grade College, Karnataka, India

2Department of Physics, Rajah Serfoji Government College, Tamilnadu, India

- *Corresponding Author:

- KV Sathish

Department of Physics,

Government First Grade College,

Karnataka,

India;

E-mail: kvsphy@gmail.com

Received date: 05 June, 2023, Manuscript No. JNPGT-23-101373;

Editor assigned date: 08 June, 2023, PreQC No. JNPGT-23-101373 (PQ);

Reviewed date: 22 June, 2023, QC No. JNPGT-23-101373;

Revised date: 04 August, 2023, Manuscript No. JNPGT-23-101373 (R);

Published date: 11 August, 2023, DOI: 10.4172/2325-9809.1000362

Citation: Sathish KV, Munirathnam R, Sridhar KN, Manjunatha HC, Sowmya N, et al. (2023) Investigation of Suitable Alloys for X-Ray/Gamma Radiation Shielding. J Nucl Ene Sci Power Generat Technol 12:6.

Abstract

The current investigation focus on the X-ray and gamma radiation shielding parameters such as mass attenuation coefficient (μ/ρ), mean free path (λ), Tenth Value Layer (TVL), effective atomic number (Zeff), specific gamma ray constant (Γ), Radiation Protection Efficiency (RPE), Kinetic Energy Released in Matter (KERMA), buildup factor, specific absorption fraction (φ) and relative dose. The different alloys such as iron-boron, iron-silicon, gallium, lead, aluminium, silicon-boron, zinc and silicon-germanium are investigated. The good absorber of X-ray and gamma radiation among each category is selected. Among the studied iron-boron alloys, Fe0.95B0.05 was found to be good absorber of X-ray and gamma radiation. Similarly, Ferro-Silicon (Fe0.21Si0.79), Galinstan (Ga0.685In0.215Sn0.1), molybdochalkos (Cu0.1Pb0.9), Ni-Ti-Al (Ti0.4Al0.1Ni0.50), Silicon-Boron alloy (Si0.95B0.05), Zinc alloy (Cu0.7Ni0.15Zn0.15) and Silicon- Germanium alloy (Si0.1Ge0.9) are found to be good absorber among the iron-silicon, gallium, lead, aluminium, silicon-boron, zinc and silicon-germanium respectively. Furthermore, to select the suitable alloy for X-ray and gamma radiation shielding, we have studied shielding properties of these selected alloys of different categories in detail. The detail investigation shows Molybdochalkos (Cu0.1Pb0.9) is a good absorber with larger value of μ/ρ, Zeff, Γ, RPE, KERMA, buildup factor, specific absorption fraction and relative dose, meanwhile smaller value of λ and TVL. As a result, molybdochalkos alloy is an effective X-ray/gamma radiation shielding material among all the studied alloys. The energies at which radiation protection efficiency is maximum (Eopt) and minimum (Es ) for a studied alloys is also identified. To use this practically, further mechanical, thermal and structural properties has to be investigated.

Keywords: Classes; Land-use; Land-cover; Kaduna metropolis; Landsat TM

Introduction

Reduction of radiation by interposing a shield of absorbing material between any radioactive source and a person, work area, or radiationsensitive device is known as radiation shielding. X-ray/gamma radiation shielding has got much concentration of researchers in recent times since in day to day life many aspects especially in research, industries, medical environments etc., are correlated with X-ray/ gamma radiation [1]. Ionizing radiation is commonly employed in business and medicine, yet it can pose a serious health risk by causing microscopic tis sue damage. Neutral radiation shielding (X-ray, gamma, neutron) has long been a fascinating field for developing effective shielding materials. Higher atomic materials are required for x-ray/gamma radiation shielding. Lower atomic materials, as well as a mix of lower atomic and higher atomic elements, are required for neutron shielding [2]. On top of that Lead was chosen as the most prominent element which is used as shielding material, akin in combination form with other material in different proportions and became prime candidate for many researchers [3-5].

Furthermore, shielding at nuclear reactors and nuclear research centers requires shielding environments against high energetic γ radiations in order to bring them into ac ceptable range [6,7]. The kinds of radiation, radioisotope activity, cost effectiveness, and exposure rate all influence the type and thickness of needed shielding material. A strong shielding material causes considerable energy loss at a short penetration distance and decreases the risk of additional hazardous radiation emission as much as feasible [8]. Since traditional radiation shielding materials namely Lead (Pb) and concrete have a number of draw backs, such as toxicity and strength, many researchers have reported on new and alternative shielding materials including glass, alloy and polymer to protect against x ray and gamma radiation [9-11]. Hence there is need of new types of alloys which will produce radiation shielding ability and good mechanical properties as well as high heat resistant properties [12].

Study of structural and mechanical properties of Al–Si alloys obtained by fast cooling of a levitated melt by taking samples by rapid cooling of levitated melts of various compositions from 11.5 to 35 wt. % Si [13]. Study of gamma, X-ray and neutron shielding properties of iron boron alloys was done by Manjunatha, et al.

Gamma, X-ray and neutron interaction parameters of Mg-Gd-Y-Zn-Zr alloys with different concentrations was studied by Seenappa, et al. Further mechanically alloyed Mo–Si-B alloys with a continuous α-Mo ma trix and improved mechanical properties of Mechanical Alloying (MA) followed by Cold Isostatic Pressing (CIP-ing) was studied by Kruger, et al. On top of that Song, et al. studied the structures and mechanical, anisotropic, electronic, transport and optical properties of Si- Ge alloys in the C2/m phase were studied. Effects of hot rolling and titanium content on the micro structure and mechanical properties of high boron Fe-B alloys by using Vacuum Induction Melting (VIM) technique was studied by Lin, et al. Moreover reviews on the influences of alloying elements on the micro structure and mechanical properties of aluminum alloys was performed by Rana et al. Further study of mechanical proper ties of magnetostrictive iron-gallium alloys was done by Kellogg et al.

The effects of Zn on the microstructure, mechanical property and corrosion behavior of the as cast Mg-Zn alloys were studied using direct observations, tensile testing, immersion tests and electrochemical evaluations was studied by Shuhua, et al. Finally lead has become prime candidate for many researchers, one among that the microstructure and mechanical proper ties of Pb-free solder alloys for low-cost electronic assembly was studied by Glaze, et al. Since radiation shielding properties include μ/ρ, μ, λ, HVL, TVL, Zeff, Ne, EABF, KERMA, SGR, SAF and RPE, previous re searchers have studied these properties with different combinations of metals [14]. Furthermore, the study of an interaction of X-rays and gamma radiation with gallium alloys done by Seenappa, et al. Earlier re searchers studied gamma, X-ray and neutron shielding parameters for the Al-based glassy alloys. Furthermore, study of radiation shielding properties of silicon polymers such as poly dimethyl siloxane, poly methyl hydro silaxane was done by Nagaraja, et al. In addition to this, study of physical, structural, optical, and radiation shielding properties of boro-bismuth glasses was studied by Abouhaswa, et al.

Radiation physicists are constantly exploring kinds of materials in terms of seeing various radiation shielding factors in order to efficiently use radiations in many do mains [15]. Due to the shortcomings of traditional shielding materials, several researchers have proposed using metallic alloys as an alternative for X-ray/gamma ray shield ing material. As a result, it is necessary to first investigate various alloys in terms of radiation shielding capabilities, categorization, and fabrication techniques which gave us motive in writing this paper [16].

Main aim of the present work is to investigate X-ray and gammaray shielding properties in Iron Boron (Fe0.95B0.05), Silicon alloys (Fe0.21Si0.79), Gallium alloys (Ga0.685In0.215Sn0.1), Lead alloys (Pb0.9Cu0.1), Aluminium alloys (Al0.1Ti0.4Ni0.5) Silicon-Boron alloys (Si0.95B0.05), Zinc alloys (Zn0.15Cu0.7Ni0.15) and Silicon Germanium (Si0.1Ge0.9) are studied. The present paper is organised as follows section II explains the materials and methods employed in the present work. The discussions and results in which detail analysis is carried out are presented in section III [17].

Materials and Methods

In the present work, x-ray and gamma-ray shielding properties of different alloys are theoretically studied in the energy range 1 keV to 100 GeV using WinXCom software. The mass attenuation coefficient or mass absorption coefficient (μ/ρ) is evaluated. The distance between any two successive collision is evaluated using mean free path. The linear attenuation is evaluated using half value layer and tenth value layer. The effective atomic number (Zeff) of a composite material is the equivalent atomic number that will generate the same effect as a single element when it interacts with photons and it is evaluated as explained in the literature. The dosage rate at a specific distance from a given quantity of a photon-emitting radionuclide is known as the specific gamma ray Constant Γ(Rm2/Cih) or gamma factor [18]. These constants are often used in radiation protection calculations. The effective shielding against x-ray and gamma ray is evaluated using Radiation Protection Efficiency (RPE). KERMA coefficients from partial photon interactions for the different alloys were studied as explained in the literature. Relative dose is also evaluated using set of equations available in reference.

Criteria for selection of good absorber of X-ray/gamma radiation

The material/medium which is having larger values of μ/ρ, Zeff, Γ, RPE, buildup factor, specific absorbed fraction and relative dose, meanwhile smaller values of mean free path, TVL and HVL are considered as good absorber of X-ray/gamma radiation. In this view, eight different alloys such as iron-boron, iron-silicon, gallium alloys, lead alloys, aluminium alloys, silicon-boron alloys, zinc alloys and silicon-germanium were considered during the detail investigations.

The selected alloy in each category with the above said criteria is follows [19].

Selection of good shielding material

Iron-boron alloys: Earlier researchers studied X-ray and γ-ray shielding properties in six different iron-boron alloys such as Fe0.95B0.05, Fe0.9B0.1, Fe0.8B0.2, Fe0.7B0.3, Fe0.6B0.4 and Fe0.5B0.5. The shielding parameters such as μ/ρ, HVL, TVL, Zeff, Γ, RPE, buildup factor and relative dose were studied. Eventually, it is found that the Fe0.95B0.05 satisfies above said criteria. Hence Fe0.95B0.05 is good absorber of X-ray/gamma radiation among iron-boron alloys. Hence, in the present study we have considered iron-boron Fe0.95B0.05 alloy for further investigation.

Silicon alloys: The different types of silicon alloys such as Al-47 (Al0.87Si0.1Ni0.008) , Al-32S (Al0.854Cu0.008Si0.12Mg0.001Ni0.008), Al-43 (Al0.95Si0.05), Ferrosilicon Fe0.21Si0.79) , Al-356 (Mg0.003Al0.927Si0.07), Al-355 (Al0.93Si0.05Cu0.013Mo0.005) and Al-A355 (Al0.92Cu0.014Si0.05Mn0.008Mg0.005Ni0.0075) were investigated. In addition to shielding parameters, the coherent/incoherent neutron scattering lengths and cross sections were also studied. Again investigations were carried for the scattering/absorption neutron cross sections of silicon alloys. Among the different studied silicon alloys, the ironsilicon Fe0.21Si0.79 alloy possesses good shielding properties. Hence, in further investigations we have used Fe0.21Si0.79 alloy.

Gallium alloys: The different gallium alloys such as galfenol Fe0.3Ga0.7, galinstan Ga0.685In0.215Sn0.1 and gallium alloy Al0.5Ga0.5 were investigated in detail. The detail analysis of shielding properties shows that galinstan Ga0.685In0.215Sn0.1 is a good shielding material with less hazardous and cost-effective material when compared to other gallium alloys studied. As a result, in subsequent studies, we employed galinstan alloy (Ga0.685In0.215Sn0.1).

Lead alloys: Literature mainly focuses on lead based alloys shielding properties. The selected alloys are as follows foundary type (Sn0.15Sb0.23Pb0.62), molybdochalkos (Pb0.9Cu0.1), lino type (Sn0.04Sb0.16Pb0.8), turne type (Sn0.2PB0.8), mono type (Sn0.09Sb0.19Pb0.72), type metal (Sn0.03Sb0.11Pb0.86), Stereo type (Sn0.06Sb0.14Pb0.8) and woods metal (Cd0.1Sn0.13Pb0.27Bi0.5). According to detail analysis, the binary alloy molybdochalkos (Pb0.9Cu0.1) has good shielding properties. As a result, in our further research, we chose molybdochalkos alloy [20].

Aluminium alloys: Around eight aluminium alloys such as Li-Al Li0.02Al0.98, hydronalium Mg0.12Mn0.01Al0.87, hiduminium Cu0.2Fe0.2Ni0.2Al0.94, italma Mg0.035Mn0.003Al0.96, magnalium Mg0.5Al0.5, Ni-Ti-Al Ti0.4Al0.1Ni0.50, duralumin Al0.9Cu0.1 and Y alloy Cu0.04Ni0.04Mg0.04Al0.88 are investigated. Exploration of all these aluminium alloys for shielding properties exhibits good absorber for Ni-Ti-Al alloy. Consequently, we explored Ti0.4Al0.1Ni0.50 alloy in further investigations.

Silicon-boron alloys: About six silicon-boron alloys such as Si0.5B0.5, Si0.6B0.4, Si0.7B0.3, Si0.8B0.2, Si0.9B0.1 and Si0.95B0.05 were explored. Using detail analysis of silicon-boron alloys, it is observed that the Si0.95B0.05 possess good shielding material. As an outcome, we conducted further research on the Si0.95B0.05 alloy.

Zinc alloys: Zinc alloys can be utilised as biodegradable metals because of their corrosion resistance and biocompatibility. The good shielding material of zinc alloys was considered using different parameters such as relative dose and SAF in the energy range 15 keV to 15 MeV. The different composition of zinc alloys such as Cu0.7Ni0.15Zn0.15, Cu0.6Ni0.2Zn0.2, Cu0.5Ni0.25Zn0.25, Cu0.4Ni0.3Zn0.3, Cu0.3Ni0.35Zn0.35 and Cu0.2Ni0.4Zn0.4 have been studied. The good shielding material is selected in such a way that the comparison of relative dose and Specific Absorbed Fraction (SAF) were found to be larger. In this way the zinc alloy i.e. Cu0.7Ni0.15Zn0.15 possess larger SAF and relative dose and in further examinations we used Cu0.7Ni0.15Zn0.15 alloy.

Silicon-germanium alloys: The neutron shielding parameters of around six silicon-germanium alloys are studied. The Si-Ge alloys such as Si0.1Ge0.9, Si0.2Ge0.8, Si0.4Ge0.6, Si0.6Ge0.4, Si0.8Ge0.2 and Si0.9Ge0.1 were investigated. Among the studied silicon-germanium alloys, the Si0.1Ge0.9 alloy possess lesser TVL, HVL and penetration depth and larger values of Γ, Zeff, RPE and kinetic energy released in matter. Then in subsequent studies, we utilised Si0.1Ge0.9 alloy.

During the detailed examinations of eight different alloys including iron-boron, silicon, gallium, lead, aluminium, silicon-boron, zinc and silicon-germanium it is seen that one of the material possess good shielding properties in each category. The selected alloy in each 4 category is based on the aforementioned criteria.

The good absorber of x-ray and gamma radiation among each category is selected. Among the studied iron-boron alloys, Fe0.95B0.05 was found to be good absorber of X-ray and gamma radiation. Similarly, Ferro-Silicon (Fe0.21Si0.79), Galinstan (Ga0.685In0.215Sn0.1), Molybdochalkos (Cu0.1Pb0.9), Ni-Ti-Al (Ti0.4Al0.1Ni0.50), Silicon- Boron alloy (Si0.95B0.05), Zinc alloy (Cu0.7Ni0.15Zn0.15) and Silicon- Germanium alloy (Si0.1Ge0.9) are found to be good absorber among the iron-silicon, gallium, lead, aluminium, silicon-boron, zinc and silicon-germanium respectively.

Results and Discussions

The parameters such as μ/ρ, λ, TVL, Zeff, Γ, RPE and KERMA is studied in the selected alloys such as Iron-Boron Alloy (Fe0.95B0.05), Ferro-Silicon (Fe-Si) alloy, Galinstan alloy (Ga0.685In0.215Sn0.1), Molybdochalkos alloy (Cu0.1Pb0.9), aluminium alloy i.e. Ni-Ti-Al Ti0.4Al0.1Ni0.50 alloy, Silicon-Boron alloy (Si0.95B0.05) alloy, Zinc Alloy (Cu0.7Ni0.15Zn0.15) and Silicon-Germanium alloy (Si0.1Ge0.9).

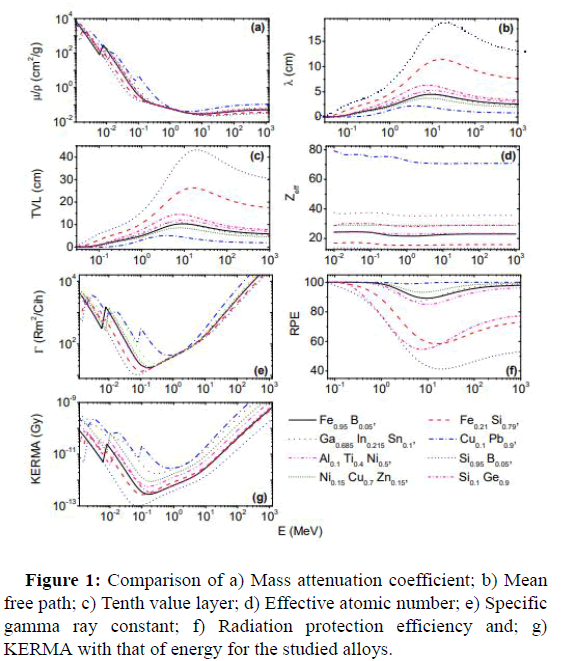

The variation of μ/ρ is studied as function of energy and it is depicted in Figure 1a. The selected eight different alloys are studied in the energy range 1 keV to 100 GeV. μ/ρ decreases with increase in energy for the studied alloys. Relatively all alloys decreases with energy, however absorption peaks were observed near 1 keV, 10 keV and 100 keV when these different alloys interact with the γ-rays. The overall behaviour of μ/ρ in lower energy region is due to photo electric effect followed by compton effect in middle region and higher energy region is mainly due to pair production. Hence, from all the studied alloys it is noticed that molybdochalkos alloy possess larger μ/ρ value when compared to other studied alloys. Further, λ is investigated as a function of energy as shown in Figure 1b. Among all the studied alloys, it is commonly observed that as the energy increases the λ i.e. distance between successive collision reaches a maximum value and again as the larger energy leads to decrease in λ. From the figure it is evident that the molybdochalkos alloy’s peak is shifted towards left side and on other side Si-B alloy’s peak is shifted towards right side. The λ is minimum in case of molybdochalkos alloy and larger when compared to Si-B alloy. Similar effect is also observed for TVL with that of energy as seen in Figure 1c. In addition, the roles of effective interaction with photons were studied and it is represented in Figure 1d.

The value of Zeff varies between 10 to 80 and among which the molybdochalkos alloy is having larger value when compared to other studied alloys. The specific gamma ray constant Γ with that of energy is shown in Figure 1e. The value of Γ decreases and reaches minimum when energy corresponds to 100 keV. However, in case of molybdochalkos alloy minimum is achieved at 1 MeV. In majority of alloys absorption peaks were observed from 1 keV to 100 keV when these alloys interact with photons. It is noticed that the Molybdochalkos alloy possess larger value when compared to other studied alloys. Later, we have also studied RPE as a function of energy as manifested in Figure 1f. The variation observed in this case is reverse as seen in Figure 1b, 1c. The larger value of RPE is observed for the molybdochalkos alloy. KERMA is also studied with the energy in the range 1 keV to 100 GeV. As similar to Figure 1e, the KERMA value also decreases and reaches minimum when energy corresponds to 100 keV. In case of molybdochalkos alloy, the minimum is obtained at 1 MeV. In majority of alloys absorption peaks were detected ranging from 1 keV to 100 keV when these alloys interact with photons. When compared to the other alloys investigated, the molybdochalkos alloy has a higher value of KERMA.

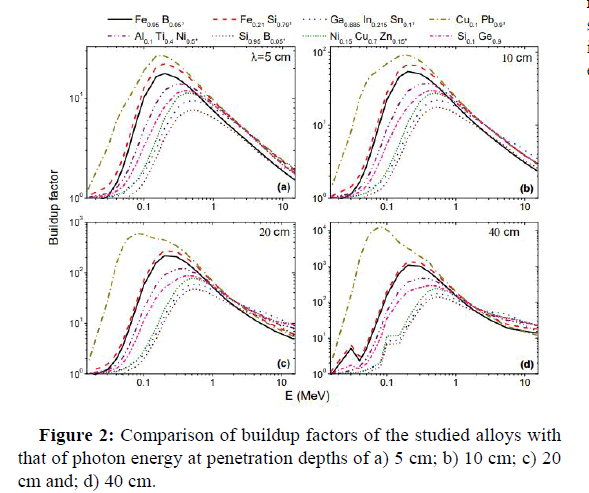

Furthermore, energy absorption buildup factors are studied for all eight selected alloys. The Figure 2 shows variation of buildup factors at different penetration depths (λ=5 cm, 10 cm, 20 cm and 40 cm) as function of energy. The buildup factor increases gradually and reaches a maximum value when energy ranges between 0.1 MeV to 1 MeV. Again in all these studied alloys buildup factor decreases with increase in energy. In all the penetration depths the observed maxima is found to be almost at the same position. The x-ray/gamma radiation absorption 5 is maximum at the energy where the absorption buildup factor is also maximum.

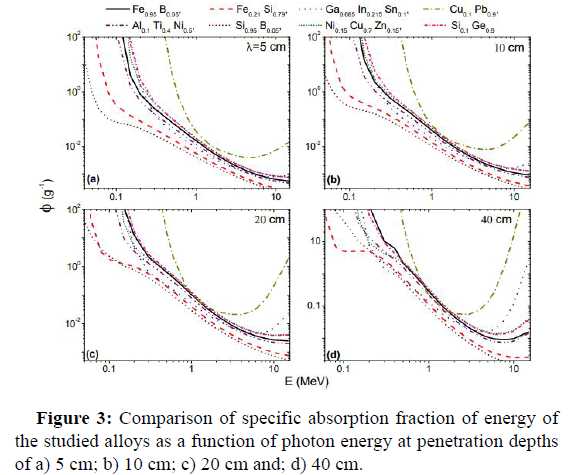

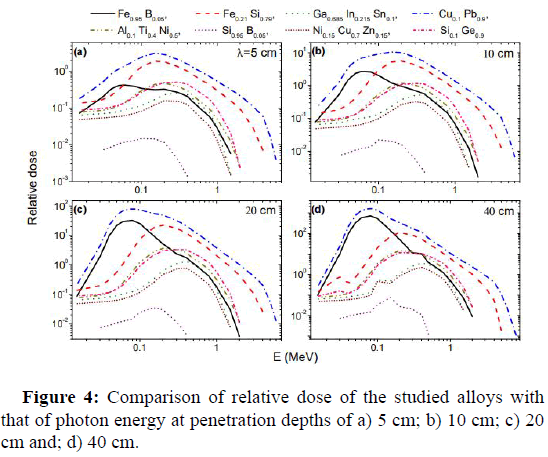

Furthermore, specific absorption fraction of energy φ(g-1) is studied in all eight different alloys at different penetration depth with the photon energy and it is shown in Figure 3a, b. The value of φ(g-1) decreases with increase in photon energy. A systematic variation is observed for all the studied alloys except molybdochalkos alloy and Galinstan alloy. In these two cases there is a gradual increase of φ(g-1) is observed when photon energy is greater than 1MeV particularly when penetrating depth is equal to 20 cm and 40 cm which is clearly visible in Figure 3c, d. This may be due to the presence of heavy element like Lead (Pb) which may leads to production of secondary radiations. The relative dose of each alloy studied is defined as the ratio of the target dose rate to the initial dose rate. A plot of relative dose as a function of photon energy is shown in Figure 4a, b at different penetration depths. From the Figure 4c, d it is seen that the value of relative dose increases and attains a maximum value and again it gradually declines. The peak value is shifted from left for FeB to right in the SiGe alloy. Similarly, larger value of relative dose is also observed when penetration depth is equal to 20 cm and 40 cm. At penetration depths, the molybdochalkos alloy possess larger value of relative dose when compared to other studied alloys. Hence, the detail investigation shows that the molybdochalkos alloy possesses larger value of μ/ρ, Zeff, Γ, RPE, KERMA, buildup factor, specific absorption fraction and relative dose, smaller value of λ and TVL. After detail investigation, it is found that λ and TVL are large at one particular energy, meanwhile, Γ, RPE and KERMA coefficients are small at the same energy for all alloys. This energy is referred as ES m and at this energy, all the alloys shows poor shielding efficiency than their neighbor energies. The evaluated ES m for studied alloys is shown in Table 1. Among all the studied alloys, molybdochalkos alloy is having large Zeff when compared to other studied alloys at minimum energy.

| Alloys | Esm (MeV) | Λ (cm) | Zeff | HVL (cm) | RPE (%) |

|---|---|---|---|---|---|

| Fe0.95B0.05 | 9 | 4.49 | 22.5 | 3.11 | 89 |

| Fe0.21Si0.79 | 16 | 11.42 | 15.73 | 7.91 | 58 |

| Ga0.685In0.215Sn0.1 | 6 | 4.85 | 35.42 | 3.36 | 87 |

| Cu0.1Pb0.9 | 4 | 2.21 | 70.82 | 1.53 | 99 |

| Al0.1Ti0.4Ni0.5 | 10 | 5.26 | 23.24 | 3.65 | 85 |

| Si0.95B0.05 | 20 | 18.74 | 13.15 | 12.99 | 41 |

| Ni0.15Cu0.7Zn0.15 | 8 | 3.72 | 28.98 | 2.58 | 93 |

| Si0.1Ge0.9 | 8 | 6.32 | 28.57 | 4.38 | 55 |

Table 1: X-ray/gamma energy at which shielding efficiency becomes minimum (ESm) and corresponding λ, Zeff, HVL and RPE (%).

The absorption buildup factor and relative dose is maximum at one energy for a given alloy. At this energy, that alloy can absorb large quantity of radiation when compare to the neighbor energies. This energy we defined as optimal energy (Eopt.) for absorption of X-ray/ gamma radiation of that alloy. At this energy, that alloy/medium can give maximum shielding efficiency. The evaluated Eopt. f or studied alloys are shown in Table 2. The value of Zeff and HVL corresponding to the Eopt. is as also tabulated in this table. This Eopt. increase with increase in the Zeff of the medium. It is also evident that the molybdochalkos alloy shows larger value of Zeff even at energy corresponding to maximum value. Hence, in general molybdochalkos alloy is having larger Zeff.

| Alloys | Eopt. (MeV) | Zeff | HVL (cm) | RPE (%) |

|---|---|---|---|---|

| Fe0.95B0.05 | 0.06 | 24.39 | 0.08 | 100 |

| Fe0.21Si0.79 | 0.2 | 15.82 | 1.58 | 99 |

| Ga0.685In0.215Sn0.1 | 0.4 | 36.13 | 1.09 | 100 |

| Cu0.1Pb0.9 | 0.15 | 75.37 | 0.03 | 100 |

| Al0.1Ti0.4Ni0.5 | 0.2 | 23.61 | 0.74 | 100 |

| Si0.95B0.05 | 0.1 | 13.21 | 1.6 | 100 |

| Ni0.15Cu0.7Zn0.15 | 0.3 | 28.99 | 0.71 | 99 |

| Si0.1Ge0.9 | 0.3 | 28.84 | 1.19 | 94 |

Table 2: X-ray/gamma energy at which shielding efficiency becomes maximum (Eopt.) and corresponding Zeff, HVL and RPE (%).

Conclusion

In the present work, we have investigated suitable alloy for X-ray/ gamma radiation shielding among the studied alloys such as ironboron, iron-silicon, gallium alloys, lead alloys, aluminium alloys, silicon-boron alloys, zinc alloys and silicon-germanium. Various shielding parameters like μ/ρ, λ, TVL, Zeff, Γ, RPE, KERMA, φ and relative dose are studied. From the detail investigations of all alloys, it is clear that molybdochalkos possesses larger value of μ/ρ, Zeff, Γ, RPE, KERMA, buildup factor, φ and relative dose. Meanwhile, smaller value of λ and TVL. Thus, we may conclude that molybdochalkos alloy is having good shielding properties. The energies at which radiation protection efficiency is maximum (Eopt) and minimum (Ems) for a studied alloys is also identified. To use this practically, further mechanical, thermal and structural properties have to be investigated.

References

- Singh VP, Badiger NM (2015) Y-ray interaction characteristics for some boron containing materials. Vac 113:24-27.

- Singh VP, Medhat ME, Badiger NM, Rahman AZ (2015) Radiation shielding effectiveness of newly developed superconductors. Radiat Phys Chem 106:175-183.

- Sathish KV, Manjunatha HC, Vidya YS, Sankarshan BM, Gupta PD, et al. (2021) Investigation on shielding properties of lead based alloys. Prog Nucl Energy 137:103788.

- Chen S, Bourham M, Rabiei A (2015) Attenuation efficiency of X-ray and comparison to gamma ray and neutrons in composite metal foams. Radiat Phys Chem 117:12-22.

- Al-Buriahi MS, Alajerami YS, Abouhaswa AS, Alalawi A, Nutaro T, et al. (2020) Effect of chromium oxide on the physical, optical, and radiation shielding properties of lead sodium borate glasses. J Non Cryst 544:120171.

- Kaur S, Kaur A, Singh PS, Singh T (2016) Scope of Pb-Sn binary alloys as gamma rays shielding material. Prog Nucl Energy 93:277-286.

- Agar O, Sayyed MI, Akman F, Tekin HO, Kacal MR (2019) An extensive investigation on gamma ray shielding features of Pd/Ag-based alloys. Nucl Eng Technol 51:853-859.

- Singh H, Sharma J, Singh T (2018) Extensive investigations of photon interaction properties for ZnxTe100-x alloys. Nucl Eng Technol 50:1364-1371.

- Kaur T, Sharma J, Singh T (2017) Thickness optimization of Sn-Pb alloys for experimentally measuring mass attenuation coefficients. Nucl Eng Technol 3:1-5.

- Aygun B, Sakar E, Korkut T, Sayyed MI, Karabulut A, et al. (2019) Fabrication of Ni, Cr, W reinforced new high alloyed stainless steels for radiation shielding applications. Results Phys 12:1-6.

- Ersundu AE, Buyukyıldız M, Ersundu Mc, Sakar E, Kurudirek MJ (2018) The heavy metal oxide glasses within the WO3-MoO3-TeO2 system to investigate the shielding properties of radiation applications. Prog Nucl Energy 104:280-287.

- Aygun B (2020) High alloyed new stainless steel shielding material for gamma and fast neutron radiation. Nucl Eng Technol 52:647-653.

- Nikanorov SP, Volkov MP, Gurin VN, Burenkov YA, Derkachenko LI, et al. (2005) Structural and mechanical properties of Al-Si alloys obtained by fast cooling of a levitated melt. Mater Sci Eng A 390:63-69.

- Sathish KV, Manjunatha HC, Seenappa L, Sridhar KN, Sowmya N, et al. (2022) Gamma, x-ray and neutron shielding properties of iron boron alloys. Mater Today Proc 49:613-619.

- Seenappa L, Manjunatha HC, Chandrika BM, Sridhar KN, Hanumantharayappa C (2018) Gamma, x-ray and neutron interaction parameters of Mg-Gd-Y-Zn-Zr alloys. Radiat Phys Chem 150:199-206.

- Kruger M, Franz S, Saage H, Heilmaier M, Schneibel JH, et al. (2018) Mechanically alloyed Mo-Si-B alloys with a continuous α-Mo matrix and improved mechanical properties. Intermetallics 16:933-41.

- Song Y, Chai C, Fan Q, Zhang W, Yang Y (2019) Physical properties of Si-Ge alloys in C2/m phase: A comprehensive investigation. J Phys Condens Matter. 31:255703.

[Crossref] [Google Scholar] [PubMed]

- He L, Liu Y, Li J, Li B (2012) Effects of hot rolling and titanium content on the microstructure and mechanical properties of high boron Fe–B alloys. Mater Des 36:88-93.

- Kellogg RA, Russell AM, Lograsso TA, Flatau AB, Clark AE, et al. (2003) Mechanical properties of magnetostrictive iron-gallium alloys. InSmart Struct Mater: Active Mater: Behav Mech 5053:534-543.

- Cai S, Lei T, Li N, Feng F (2012) Effects of Zn on microstructure, mechanical properties and corrosion behavior of Mg–Zn alloys. Mater Sci Eng C 32:2570-2577.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi