Research Article, J Nucl Ene Sci Power Generat Technol Vol: 12 Issue: 3

Powering Sustainable Transport: A Comprehensive Analysis of Battery Pack Design and Performance in Electric Vehicles

Abhishek Kamlesh, Ritik Solanki, Divya Sharma*, Usha Chauhan and Tarannum Bahar

1Department of Electrical, Electronics and Communication Engineering, Galgotias University, Greater Noida, India

*Corresponding Author: Divya Sharma,

Department of Electrical, Electronics and

Communication Engineering, Galgotias University, Greater Noida, India

E-mail: divyasharma@galgotiasuniversity.edu.in

Received date: 12 May, 2023, Manuscript No. JNPGT-23-98711;

Editor assigned date: 15 May, 2023, PreQC No. JNPGT-23-98711 (PQ);

Reviewed date: 31 May, 2023, QC No. JNPGT-23-98711;

Revised date: 09 June, 2023, Manuscript No. JNPGT-23-98711 (R);

Published date: 16 June, 2023, DOI: 10.4172/2325-9809.1000333.

Citation: Kamlesh A, Solanki R, Sharma D, Chauhan U, Bahar T (2023) Powering Sustainable Transport: A Comprehensive Analysis of Battery Pack Design and Performance in Electric Vehicles. J Nucl Ene Sci Power Generat Technol 12:3.

Abstract

This research paper focuses on the design of a battery pack for electric vehicles. A MATrix Laboratory (MATLAB) simulation of a drive cycle was conducted to determine the current requirements of the vehicle at different speeds. The simulation provided data on speed vs. time, allowing for the analysis of different battery types such as nickel-cadmium, lithiumpolymer, and lithium-ion. The simulation also helped to derive different battery parameter values such as voltage, current, and state of charge. The objective of this research is to determine the best battery configuration for optimum performance in electric vehicles.

Keywords

Battery pack design; Lithium-ion battery; Battery thermal management; Battery cycle life; State of charge

Introduction

The increasing demand for sustainable transportation has led to the development of Electric Vehicles (EVs). One of the key components in the design of EVs is the battery pack. The battery pack is responsible for storing and providing energy to power the vehicle's motor. As such, it is critical to design a battery pack that meets the performance and safety requirements of EVs [1].

In this research paper, we focus on the design of a battery pack for EVs. To determine the best battery configuration for optimum performance, a MATLAB simulation of a drive cycle was conducted. The simulation provided data on current vs. time, which was analyzed for different battery types such as nickel-cadmium, lithium-polymer, and lithium-ion. The simulation also helped to derive different battery parameter values such as voltage, current, and state of charge.

The objective of this research is to determine the best battery configuration for EVs, taking into consideration performance, safety, and cost factors [1]. The findings of this research can provide insights for the design of future battery packs for EVs, contributing to the development of more sustainable and efficient transportation solutions.

Material and Methods

Battery pack

A battery pack is a collection of individual batteries arranged in a specific configuration to provide a desired voltage, current, and energy output. The battery pack is an essential component of an electric vehicle as it provides the necessary energy to power the vehicle's motor [2]. The configuration of the battery pack depends on the specific requirements of the vehicle, such as the desired range, power output, and weight. The most commonly used battery chemistries in battery packs for electric vehicles are nickel-cadmium, lithiumpolymer, and lithium-ion.

Battery parameters

There are several parameters that are used to describe the characteristics of batteries. Some of the most important battery parameters include:

Voltage: Voltage is the electrical potential difference between two points in a battery. It is measured in Volts (V) and determines the amount of power that can be delivered to the motor.

Current: Current is the flow of electric charge through a battery. It is measured in Amperes (A) and determines the rate at which the battery can supply energy to the motor.

State of Charge (SOC): The state of charge is the percentage of the total capacity of the battery that is currently available. It is measured in percentage and indicates the amount of energy that is available for use.

Cycle life: Cycle life refers to the number of charge and discharge cycles that a battery can withstand before it reaches the end of its useful life. It is an important parameter as it determines the lifespan of the battery [3].

Battery Management System (BMS): The battery management system is responsible for monitoring and controlling the performance of the battery. It ensures that the battery operates within safe limits and can also provide information on the state of charge and other important parameters.

Battery thermal management: Battery thermal management is the process of regulating the temperature of the battery to ensure that it operates within safe limits. High temperatures can reduce the lifespan of the battery and increase the risk of thermal runaway, which can lead to fires or explosion [4].

Battery pack designing

Battery pack designing is a critical aspect of Electric Vehicle (EV) design. A battery pack typically consists of multiple cells that are interconnected to provide the required voltage and current to power the EV's motor. The design of a battery pack involves selecting the right type of cells, arranging them in a suitable configuration, and incorporating safety features to prevent any potential hazards.

The selection of cells is a crucial aspect of battery pack design. Different types of cells, such as nickel-cadmium, lithium-polymer, and lithium-ion, have their own unique characteristics in terms of energy density, cycle life, and cost. The choice of cells is often driven by factors such as performance, safety, and cost-effectiveness.

The arrangement of cells in a battery pack depends on the voltage and current requirements of the EV. The cells can be connected in series to increase the voltage or in parallel to increase the current. The arrangement should be optimized to provide the required power output while also ensuring that the cells are balanced and do not experience any thermal runaway.

In addition to cell selection and arrangement, battery pack designing also involves incorporating safety features such as thermal management, overcharge protection, and cell monitoring. These features help to prevent any potential hazards such as fires or explosions [5].

Overall, battery pack designing is a critical aspect of EV design that requires careful consideration of various factors such as cell selection, arrangement, and safety features. A well-designed battery pack can ensure the performance, safety, and cost-effectiveness of EVs, contributing to the development of sustainable and efficient transportation solutions.

Existing models

Chevrolet Volt battery pack design: The Chevrolet Volt is an electric vehicle that also includes an onboard gasoline generator to extend its range. The first-generation Volt battery pack design utilized a T-shaped configuration that was difficult to manufacture and prone to battery cooling issues. While the battery pack did provide sufficient power, its manufacturing complexity and reliability issues led to a redesign in the second-generation Volt [5].

Fisker Karma battery pack design: The Fisker Karma was a luxury electric vehicle that utilized a unique battery pack design. The pack consisted of two battery modules each with 15 kWh capacity, mounted low in the vehicle’s centre for optimal weight distribution, however the battery pack faced numerous issues including fire hazards and module failure leading to recall of the vehicle.

Tesla model S battery pack design: The Tesla model S is a highly popular and successful electric vehicle, but its battery pack design faced challenges in the early stages of production [5]. The original design used thousands of small lithium-ion cells, which led to manufacturing complexity and quality control issues. Tesla eventually switched to a simpler and more reliable design using larger battery cells [5].

Results and Discussion

Simulation observations

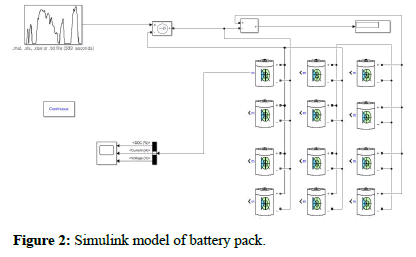

Since these observations are recorded by simulation, it is important to show the nature and parameters of battery. In MATLAB the discharging graph and different parameters of the Li-ion battery and Lead acid batteries is shown in the Figure 1. Also in Table 1 we can observe parameter such as discharge time, energy density comparison of lithium-ion battery with other batteries and notice that li-ion battery outperforms other battery type in same segment, thus becoming best choice for battery pack designing.

| Battery type | Voltage (V) | Energy density (Wh/kg) | Discharge time for 5 mm thickness (hh:mm:ss) | Discharge time for 1 mm thickness (hh:mm:ss) |

|---|---|---|---|---|

| Ni-Cd | 1.2 | 40-100 | 11:15:00 | 00:05:24 |

| Ni-MH | 1.2 | 90-245 | 27:36:00 | 00:13:12 |

| Li-ion | 1.5 | 110-220 | 45:00:00 | 00:21:36 |

| Li-polymer | 3.6 | 180-380 | 42:45:00 | 00:20:24 |

Table 1: Comparision of different parameters.

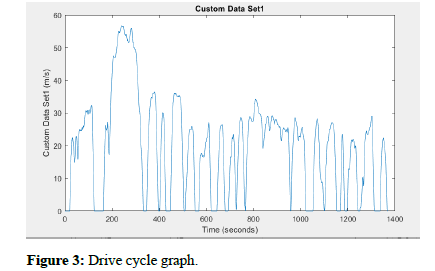

The parameters help in determining or predicting the performance of the battery. Based on this the simulation has done and the battery pack had been designed. According to the model shown in Figure 2.

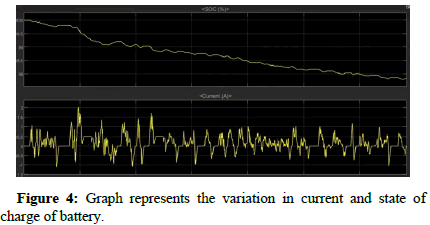

Since this simulation focus on the performance of Electric Vehicle, hence to simulate the behaviour of the Electric Vehicle a drive cycle is used.

A drive cycle is numerical data represented in the form of graph in MATLAB which gives relationship between either Speed vs. Time or Current vs. Time.

The drive cycle used in this simulation is specially designed and observed to simulate the behavior of an electric vehicle driving in the cities where it needs to stop suddenly and frequently [6]. The drive cycle graph is shown in this Figure 3.

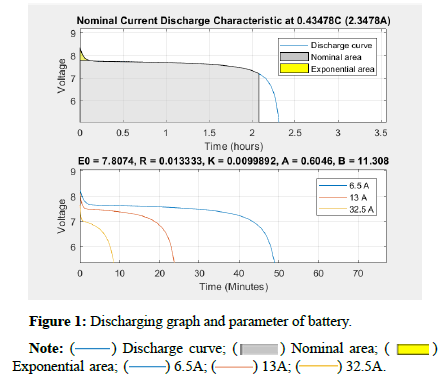

This drive cycle gives data to current generator based on the drive cycle which is connected to the battery pack [6]. The parameters of battery like State of Charge (SOC), current and Voltages are then observed using a bus and plotted using Scope (Figure 4).

These are the result and observations of this model after using this drive cycle, the model has undergone a specific testing procedure, and the findings and analysis obtained from this testing procedure are being presented. These findings and analysis can provide insights into the performance of the system being tested, which can be used to improve its efficiency, reliability, and overall performance [5,6]. The current model is a solid foundation for further experimentation and exploration. By conducting further research and testing using different drive cycles and batteries, researchers can gain a deeper understanding of the system being studied and potentially uncover new insights that can be used to improve its performance [7-10].

Using different drive cycles can help researchers evaluate the system's performance under a wider range of conditions, which can provide a more comprehensive view of its capabilities. By testing the system under different conditions, researchers can identify any weaknesses or limitations that may not have been apparent during the initial testing.

Conclusion

Battery is very critical part of any electric vehicle unit, and hence it is very important to understand to choose the type and configuration of the batteries for designing a battery pack which can provide the optimum performance of the unit. This paper looks into this and provides a very basic model for simulating and investigating the performance of different battery packs and observes their performances. It also helps researchers to find the minor faults or flaws in performance based on the analysis of the observations.

References

- Casals LC, Garcia BA, Canal C (2019) Second life batteries lifespan: Rest of useful life and environmental analysis. J Environ Manage 232:354-363.

- Deng Y, Zhang Y, Luo F, Mu Y (2020) Operational planning of centralized charging stations utilizing second-life battery energy storage systems. IEEE Trans Sustain Energy 12(1):387-399.

- Essiet IO, Sun Y (2021) Optimal Open-Circuit Voltage (OCV) model for improved electric vehicle battery state-of-charge in V2G services. Energy Reports 7:4348-4359.

- Hu L, Ye Y, Bo Y, Huang J, Tian Q, et al (2022) Performance evaluation strategy for battery pack of electric vehicles: Online estimation and offline evaluation. Energy Reports 8:774-784.

- Jiang L, Deng Z, Tang X, Hu L, Lin X, et al (2021) Data-driven fault diagnosis and thermal runaway warning for battery packs using real-world vehicle data. Energy 234:121266.

- Zhang Z, Zhang L, Hu L, Huang C (2020) Active cell balancing of lithium‐ion battery pack based on average state of charge. Int J Energy Res 44(4):2535-2548.

- Baek SY, Baek SM, Jeon HH, Kim WS, Kim YS, et al (2022) Traction performance evaluation of the electric all-wheel-drive tractor. Sensors. 22(3):785.

- González-Castaño C, Restrepo C, Kouro S, Vidal-Idiarte E, Calvente J (2021) A bidirectional versatile buck–boost converter driver for electric vehicle applications. Sensors 21(17):5712.

- Sun B, Gu T, Xie M, Wang P, Gao S, et al (2022) Strategy design and performance analysis of an electromechanical flywheel hybrid scheme for electric vehicles. Sustainability 14(17):11017.

- Tang X, Guo Q, Li M, Wei C, Pan Z, et al (2021) Performance analysis on liquid-cooled battery thermal management for electric vehicles based on machine learning. Journal of Power Sources 494:229727.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi

) Discharge curve; (

) Discharge curve; ( ) Nominal area; (

) Nominal area; ( )

Exponential area; (

)

Exponential area; ( ) 6.5A; (

) 6.5A; ( ) 13A; (

) 13A; ( ) 32.5A.

) 32.5A.