Mini Review, J Nucl Ene Sci Power Generat Technol Vol: 14 Issue: 1

Recent Progress of Phase Change Materials Towards Battery Thermal Management Applications

Changren Xiao*, Mingshuo Zhan and Yakun Le

1School of Chemistry and Chemical Engineering, Jinggangshan University, Ji’an, China

*Corresponding Author: Changren Xiaoa,

School of Chemistry and

Chemical Engineering, Jinggangshan University, Ji’an, China

E-mail: xiaochangren@jgsu.edu.cn

Received date: 17 September, 2024, Manuscript No. JNPGT-24-148191;

Editor assigned date: 19 September, 2024, PreQC No. JNPGT-24-148191 (PQ);

Reviewed date: 03 October, 2024, QC No. JNPGT-24-148191;

Revised date: 11 October, 2024, Manuscript No. JNPGT-24-148191 (R);

Published date: 18 October, 2024, DOI: 10.4172/2325-9809.1000414.

Citation: Xiao C, Zhan M, Le Y (2024) Recent Progress of Phase Change Materials Towards Battery Thermal Management Applications. J Nucl Ene Sci Power Generat Technol 13:5.

Abstract

It is of great significance to design an advanced power battery thermal management system for power battery. Among various system Phase Change Materials (PCM) cooling system has attracted extensive attention attributing to it’s simple in structure but having excellent performance. However, the defect of core materials PCM tightly restricted the industrial promotion of this emerging technology. Therefore, a minireview was written to summarize the modification strategies improving PCM’s essential properties i.e. thermal conductivity, shape collapsing and leakage concerns, as well as highly inflammable. Profound conclusions concerning about the prospect and challenges of PCM for thermal management applications were given. It was expected to provide some innovative ideas for the advancement of such capable technology.

Keywords: Battery thermal management; Phase change

materials; Passive cooling; Materials modification

Introduction

During the charge-discharge cycling process, temperature and temperature difference within lithium-ion battery modules significantly affect cell consistency, a fact that is now widely recognized in the industry [1]. Efficient battery thermal management systems have become a standard feature in Electric Vehicle/ Plug-In Hybrid Electric Vehicles (EV/PHEV) available on the market. Compared to the widely used air and liquid cooling technologies in EV/PHEV applications, phase change material battery thermal management technology offers superior temperature control and homogenizing capability, a compact structure and no need of extra energy consumption [2]. PCM cooling represents an emerging technology in battery thermal management system. However, the main challenge for its industrialization lies in the PCM itself. Currently, PCMs developed for battery thermal management still suffer from low thermal conductivity, poor thermal stability and inadequate flame retardancy [3]. This mini-review aims to summarize significant research advancements addressing these issues, with the goal of promoting the further development of PCM for battery thermal management system.

Literature Review

Enhancement of thermal conductivity

Power battery modules are characterized by high charge/discharge rates and substantial heat generation. However, the thermal conductivity of PCMs used in thermal management is usually low, preventing the rapid transfer of tidal heat generated during charge and discharge processes to the PCM. This leads to heat accumulation within the cells and a sharp rise in temperature, significantly weakening the performance of the battery thermal management system. Commonly used PCM in battery thermal management, such as fatty hydrocarbons and their derivatives, typically have a thermal conductivity of about (0.2 W/mK). Researchers often enhance the thermal conductivity by incorporating high-conductivity fillers into PCM. However, adding these fillers significantly reduces the heat storage density of the composite material. To address this issue, researchers are currently constructing low-density continuous thermal conductive networks within the PCM matrix, which alleviates latent heat attenuation while maintaining heat transfer efficiency. Commonly used thermal conductive fillers for PCMs include expanded graphite, graphene, carbon nanotubes, metal foams and porous ceramics. PCM modified using these methods generally meets the thermal control and homogenizing needs of power batteries.

Improvement of its thermal stability

PCM applied for thermal management typically absorbs heat through solid-liquid phase change. Once the PCM reaches thermal saturation, its shape collapses and transforms into a liquid state that is prone to leakage, which is detrimental to the long-term running of such system based on PCM cooling technology. To improve the thermal stability and anti-leakage performance of PCMs, researchers have employed physical and chemical modification methods, detailed as follows.

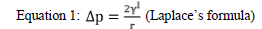

Physical modification methods: Physical methods involve incorporating adsorbents into PCM to utilize additional pressure generated by capillary action as shown in equation 1 to tightly bind the phase change segments within the porous structure of the adsorbent, thereby enhancing the shape stability and leakage-proof performance. Similar to the addition of thermal conductive fillers, adding adsorbents to the PCM matrix significantly reduces its phase change enthalpy. Current strategies to address this issue can be categorized as follows:

Using low-density, high-porosity adsorbents: Select adsorbents with low density and high porosity as the adsorption framework for PCM. This approach significantly reduces the latent heat decay rate while maintaining material thermal stability. For instance, Hong et al., used polyethylene glycol aerogels as adsorption frameworks for PCMs, achieving a substantial improvement in thermal stability while maintaining a latent heat of 178.6 J/g [4].

Using multifunctional porous materials: Employ multifunctional porous materials as adsorbents to achieve multiple functions with a single type of filler, thereby reducing the filler content in the PCM matrix and decreasing the latent heat decay rate. For example, Hu et al., selected Mxene/graphene aerogels as adsorption frameworks for PCMs. These composite materials not only maintain good thermal stability but also exhibit a high storage density of up to 160.3 J/g and an exceptionally high planar thermal conductivity of 11.39 W/mK [5].

In summary, physical modification methods are simple but effective, significantly enhancing the thermal stability of PCMs through the addition of fillers. This is currently one of the most widely used modification strategies.

where Δp represents the capillary adsorption force, γ1 is the surface tension of the liquid PCM and r is the radius of the adsorbent’s capillary pore. When r is very small, the interface effects of the curved liquid surface are significant, resulting in a strong capillary adsorption force.

Chemical modification methods

While physical modification methods can improve the thermal stability of PCMs, achieving intrinsically thermally stable PCMs remains challenging. Compared to physical methods, chemical modification methods can prepare PCMs with intrinsic solid-solid phase transition characteristics, thoroughly addressing issues of poor shape stability and leakage. Based on the preparation process, chemical modification methods can be categorized as follows.

Grafting phase change molecules onto rigid polymer chains: For example, Shi et al., grafted aliphatic alkyl groups onto ethylene-maleic anhydride copolymers to prepare solid-solid PCMs [6]. The resulting samples demonstrated excellent thermal stability, with no leakage or deformation observed at extreme temperatures of 160℃ and no decay in thermal storage density over 500 charge/discharge cycles.

Polymerizing side chains with phase change characteristics: For instance, Xiao et al., synthesized a series of comb-like polymer PCMs with phase change temperatures through radical copolymerization of methyl methacrylate and dipropylene glycol diacrylate [7]. These PCMs not only exhibited solid-solid phase change characteristics but also maintained no leakage or deformation after thermal saturation. Under optimal conditions, the latent heat of the PCM can reach up to 88.23 J/g [8].

Synthesizing phase change functional polymers with soft segments (alkoxy) and rigid segments: Zou et al., synthesized main chain type phase change functional polymers through the stepwise polymerization of polyethylene glycol and hexamethylene diisocyanate [9]. The resulting polymers exhibited intrinsic solid-solid phase change characteristics and shape stability, with excellent flexibility, showing potential applications in wearable devices.

Although chemical modification methods can produce samples with excellent thermal stability, they often result in significant changes to crystallization characteristics, such as phase change temperature and supercooling, with a substantial reduction in latent heat and unclear impact mechanisms. Therefore, this type of modification method still has certain limitations.

Discussion

Enhancing flame retardancy

Currently, PCMs employed in battery thermal management often contain highly flammable elements such as Carbon (C) and Hydrogen (H). In extreme conditions, such as thermal runaway in batteries, the inherent properties of PCMs not only fail to suppress the spread of thermal runaway but may even accelerate it. These factors make it challenging to industrialize PCM-based battery thermal management technologies despite their excellent temperature control and homogenizing performance. Therefore, enhancing the flame retardancy of PCMs has become a research hotspot in recent years. Adding flame retardants to PCMs is a common and effective modification strategy. Moreover, the use of halogen-free flame retardants avoids environmental pollution risks associated with halogenated flame retardants. For instance, Weng et al., reduced the peak heat release rate of PCMs from 242.5 kW/m² to 204.4 kW/m² by adding Al(OH)₃ to the PCM matrix, improving the Safety Factor (FOS) from 16.7 to 21.0 and significantly enhancing the thermal runaway delay rate [8]. Introducing flame retardant elements into the PCM molecular chains is also an effective strategy to improve the flame retardancy and obtain intrinsically flame-retardant materials. Zou et al., introduced phosphorus elements through chemical reactions and further blended them with pentaerythritol phosphate to enhance the flame retardancy of PCMs [9]. The modified material reduced the peak heat release rate by 50% and not only exhibited enhanced flame retardancy but also a high energy density, with a latent heat of 186.9 J/g.

Conclusion

Modification strategies improving PCM’s pivotal properties i.e. thermal conductivity, shape collapsing and leakage concerns, as well as highly inflammable were summarized in this mini review. The main conclusions drawn from this review are as follows:

• The thermal conductivity of phase change materials can be enhanced to exceed 1 W/(mK) through the incorporation of thermally conductive fillers, which mitigates a major limitation for the industrial advancement of battery thermal management systems.

• Challenges in industrializing battery thermal management technology include the fracture, deformation and collapse of PCM modules during the battery’s charge/discharge cycles and the prolonged heat storage/release processes.

• While the integration of flame retardants such as Nitrogen (N), Phosphorus (P), Halogen (X) compounds or inorganic char-forming catalysts can improve material flame resistance to some degree, these measures still fall short under extreme conditions like thermal runaway in batteries.

Acknowledgement

We are thankful to Doctoral Scientific Research Initiation Foundation of Jinggangshan University (JZB2116).

References

- Yang H, Zhang G, Dou B, Yan X, Lu W, et al. (2024) Review on the lithium-ion battery thermal management system based on composite phase change materials: Progress and outlook. Energ Fuel 38(4):2573-2600.

- GaneshKumar P, Sivalingam V, Divya S, Oh TH, Vigneswaran VS, et al. (2024) Thermophysical exploration: State-of-the-art review on phase change materials for effective thermal management in lithium-ion battery systems. J Energy Storage 87:111412.

- Liu H, Shi G, Mei J, Li Q, Wang Z (2024) Experimental study on the thermal management performance of lithium‐ion battery using phase‐change material at various ambient temperatures. Energy Technol 12(1):2300790.

- Hong W, Liu Z, Chen J, He G, Wang P, et al. (2024) Shape-stabilized phase change materials based on polyvinyl alcohol/graphene hybrid aerogels for efficient solar-thermal energy conversion. Mater Sci Semicond Process 169:107931.

- Hu B, Guo H, Li J, Li T, Cao M, et al. (2023) Dual-encapsulated phase change composites with hierarchical Mxene-graphene monoliths in graphene foam for high-efficiency thermal management and electromagnetic interference shielding. Compos B Eng 266:110998.

- Li S, Kong L, Wang H, Xu H, Li J, et al. (2018) Thermal performance and shape-stabilization of comb-like polymeric phase change materials enhanced by octadecylamine-functionalized graphene oxide. Energy Convers Manag 168:119-27.

- Xiao C, Yin X, Chen J, Wang Y, Liao W, et al. (2024) Single‐step preparation of intrinsic solid-solid phase change materials with excellent anti‐leakage and form‐stable performance. J Appl Polym Sci 141(35):e55876.

- Weng J, Xiao C, Ouyang D, Yang X, Chen M, et al. (2022) Mitigation effects on thermal runaway propagation of structure-enhanced phase change material modules with flame retardant additives. Energ 239:122087.

- Chen R, Huang X, Zheng R, Xie D, Mei Y, et al. (2020) Flame-retardancy and thermal properties of a novel phosphorus-modified PCM for thermal energy storage. J Chem Eng 380:122500.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi