Research Article, J Nucl Ene Sci Power Generat Technol Vol: 11 Issue: 6

Technological Background of an Improved Nuclear Reactors

Gurjot Singh1*, Neeraj Kaushik2 and Manoj Ojha3

1Department of Physics, Faculty of Science, SGT University, Gurugram, Haryana, Tunsia, India

2Department of Electrical and Electronic Engineering, Teerthanker Mahaveer University, Uttar Pradesh, India

3Department of Electrical and Electronic Engineering, Sanskriti University, Mathura, Uttar Pradesh, India

*Corresponding Author: Gurjot SinghDepartment of Physics, Faculty of Science,SGT University, Gurugram, Haryana, Tunsia, India; E-mail: gurjot_fosc@sgtuniversity.org

Received date: 09 February, 2022, Manuscript No. JNPGT-22-47022; Editor assigned date: 11 February, 2022, PreQC No. JNPGT-22-47022 (PQ); Reviewed date: 25 February, 2022, QC No. JNPGT-22-47022; Revised date: 13 April 2022, Manuscript No. JNPGT-22-47022 (R); Published date: 02 May 2022, DOI: 10.4172/2325-9809.1000287

Citation: Gurjot S, Neeraj K, Manoj O (2022) Technological Background of an Improved Nuclear Reactors. J Nucl Ene Sci Power Generat Technol 11:6.

Abstract

Advanced nuclear reactors are being built to change their energy production more rapidly to meet demand, assisting in grid stabilization in regions where intermittent renewables are abundant. Freshwater, molten salt, high-temperature gas, as well as liquid metal will all be used in advanced reactors as coolants. The use of heat and other types of energy produced as a by-product by nuclear power reactors for desalination processes, hydrogen generation, district heating, and other industrial uses is gaining popularity. At the end, the researchers concluded that the most advanced light water Small Modular Reactor (SMR) model is a 60 MW reactors module designed by NuScale Power in the United States. The designs were chosen based on a variety of criteria, including safety, sustainability, affordability, security protocols, proliferation resistance, as well as waste reduction. The implementation of these innovations discussed in this paper might begin by 2030 and are projected to achieve commercialization before 2050.

Keywords: Advanced reactors; Fusion reactor; Neutron; Nuclear reactors; Water cooled reactor

Introduction

Computing environments offer large virtual labs for all engineering design endeavors, allowing concepts to develop into complex, well-optimized systems. Because of the complicated physics as well as high experimental costs in the nuclear sector, using virtual facilities has always been and continues to be critical to development. In fact, in 1945, Edward Teller used the world's first computer system explaining deuterium-tritium behaviour to calculate differential equations, bringing contemporary computing as well as nuclear technology together. Analytical techniques guided by tests were used to develop the first nuclear reactors. To complement shielding as well as core design efforts, radiation transport issues were soon addressed numerically on early computers.

Researchers used an IBM 604 to solve a neutron diffusion equation for the first time. Fortran programming language was first primarily on IBM 704 computers in 1957, along with enormously powerful machines, allowed for the numerical treatment of increasingly complex physics. Extensive nuclear data collections, a crucial feed to reactor simulation depicting reaction probabilities, were made possible by advancements in storage technology at the same time. Exploratory central mock-up operations use zero-power essential arrangements of fuel tanks to test new reactor conceptual designs today [1].

Reactor simulation software improved in precision for individual physics issues from the 1970s to the 1990s, including neurotics, performance of fuel, heat transport. Individual professionals were responsible for comprehending the extent of application and functioning of these codes, which were mainly created independently of one another. Many times, engineering teams created conventional data transmission formats that allowed for a more manual process, but effective, handling of the whole system. In the novel reactors region, significant modelling work has been made on extremely high model equations that utilize contemporary computer designs to minimize approximations. Many commercialized programmes now perform some simple physics connection. The current multi-physics simulation initiatives are a scientific undertaking aiming at decreasing uncertainties, improving knowledge, and providing predictive capabilities. Nevertheless, they are not yet intended for direct use by industry [2].

Terra Power launched the Traveling Wave Reactor (TWR) programme in 2006 with the goal of developing accessible, sustainable, and carbon low energy. For many rapid reactor functions, the TWR uses a formerly deep fuel cycle. It was a penultimate sodium-cooled metal-fuelled TWR. The basic viability of the TWR architecture was proved using high-fidelity (yet decoupled) physics simulations. To support the changing reactor design, additional software was created and purchased as the company expanded.

By using the Advanced Reactor Modeling Interface (ARMI) primary goal, scientists want to develop a single fusion reactor toolset that incorporates new and existing physics prediction models with managing data and automated processes. With a relatively clean palate and a new group, it was possible to apply new architectural principles and software methods to the challenge of creating a very speedy, flexible, and interconnected reactor. Also when infrastructure and data management evolved, consultants concentrated on developing more physics components and adapters to fairly complex physics answers.

Since the tools were linked, any team member could perform the full system analysis in real time, from defining pin size and tolerances to calculating system cost as well as peak cladding temperature throughout design-basis transients. It would be simple to conduct detailed and significant design, innovation, as well as sensitivity studies. Terra-Power has been able to create its ideas with ambitious timeframes and small, dynamic teams because to this approach [3].

In the United States, the nuclear power sector is experiencing serious economic difficulties. High capital costs, slow increase in energy demand, and the competitiveness from low-cost sources of energy like biogas and alternatives has slowed the construction of new reactors, causing those already in operation to be retired sooner. The number of resignations is expected to rise as ageing reactors enter the final of their operational licenses in 2030 and beyond. In addition, recent attempts to construct supplementary nuclear power plants have been hampered by cost and schedule over runs [4].

Light Water Reactors (LWRs), originally commercialized in the 1950s and now located all over the globe, produce all of the nuclear power generation used in the United States. As a side consequence of using ordinary cooling water massive water reactors, those neutrons required for the row of dominoes are slowed. With a 1,000 megawatt power producing capability or more, conventional LWRs are huge enough to distribute their high building costs over as many kilowatt-hours as possible during their lifetime. While ordinary reactors confront an uncertain future, many members of Congress believe that in order to decrease carbon emissions and provide low-carbon energy, more nuclear power facilities are required to the bulk of the worldwide people, not fewer.

They believe that the only way to boost the quantity of nuclear power stations is to create more advanced nuclear technology, which they claim can solve the financial obstacles, security issues, as well as other problems that have hindered the growth of regular LWRs. According to a law enacted by the United States Congress, an upgraded nuclear reactor is defined as a conventional fission reactor with significant improvements over the most recent period of nuclear fusion engines [5].

Apart from the reduction of greenhouse gas, proponents of nuclear power claim a number of reasons for maintaining and growing the nuclear sector in the United States. They argue that a huge local nuclear energy industry will indeed help achieve goals like energy security as well as electricity grid flexibility, divergence, dependability, for indigenous nuclear element production and exports, for clean air and also for the maintenance of hegemonic power, and for these causes.

Nuclear energy is used by the US Navy to power submarines as well as aircraft carriers. Some people believe that the government and other secret services profit from nuclear power's continued use because it provides numerous naval power plant employees with a post-military career as well as continuing to expand the base of competent scientists and engineers and bolstering the architectural features for training and knowledge transition [6].

In recent years, the advanced nuclear sector in the United States has grown to include a diverse group of developers, distributors, and support organizations. As of November 2018, there were 35 United States firms researching advanced nuclear reactor technology, according to one estimate. According to some estimates, the first advanced reactor in the United States may start supplying energy to the grid even by mid-2020. For example, NuScale, a firm that develops advanced reactors, estimates that its first power station will be operational in 2026 [7].

Literature Review

Technologies for advanced reactorsAdvanced or unorthodox reactor designs aim to improve on previous generations of fission plants in many of the following categories: cost, safety, privacy, waste management, and flexibility by combining fresh and innovative technologies and materials. Advanced designs may have one or more of the features:

- Passive and inherent safety measures.

- Modular or simpler designs.

- Closed fuel cycles.

- Enriched load capabilities.

- Upgraded physical and chemical steadiness.

- Instant neutron ranges.

Current industrial power plants are known as Generation III or Generation III+, depending on when they were constructed, while newer reactor methods are alluded to that as Generation IV nuclear reactors [8]. There are three main types of advanced reactor designs. A more efficient and simpler architecture for water-based fission reactors that provide incremental improvements to existing water-based fission techniques. This is a nuclear power plant that uses coolants apart from water to maintain a safe operating temperature, and Reactor designs that generate energy via splitting large nucleus, instead of those that practice fission, aim to produce energy by merging tiny atomic nuclei.

It's possible to classify a small flexible reactor as just a Small Modular Reactor (SMR). Plants with a capacity of less below 300 megawatts, known as SMRs, "use modular building techniques, transport key components from the manufacturing fabrication locations to the site through rail and vehicle, and also feature features that ease plant placement operations involved in plant installation", according to the Department of Energy.

SMRs may be constructed from sophisticated water-cooled reactors as well as non-water-cooled reactors. Micro-reactors are small-capacity SMRs that can create thermal energy up to 1 to 20 megawatts, that is utilized immediately to produce electricity or as industrial heating, according to the Department of Energy. According to the DOE, micro-reactors may be carried by truck and deployed in a distant area or military post in as little as a week [9].

A spectrum of technical maturity may be used to classify advanced reactor designs. Molten salt reactors, fuel fast reactors, as well as fusion reactors are all thought to be a long way off from being commercially viable. Experts predict that the first compact modular LWRs will be commercialized in the mid-2020s, with certain advanced reactor ideas, like molten salt reactors as well as gas-cooled fast reactors, arriving in the mid-century or later. Companies working on comparable reactor technology may be at various levels of development and production [10].

Innovative Water-Cooled ReactorsSmall modular light water reactors: It is estimated that by 2030 there will be at least 300 compact modular reactors operating in United States, looking at the present average throughput of approximately 1,000 MW inside the country. However, they are typically small enough to accommodate all of the major reactor elements into a solitary pressure vessel for SMR concepts for power reactors depending on the traffic LWR technology.

When compared to large LWRs, the containment vessel and its equipment will be constructed in a facility before being brought to the processing facility for assembly, which may save construction costs and time. According to supporters of the concept, mass manufacture of huge numbers of similar SMRs may significantly decrease manufacturing costs and building timelines [11].

Reduced interest payments and shorter payback periods may be achieved by reducing the time it takes for a new reactor to start generating income. Furthermore, even while each SMR might need less investment than a large conventional nuclear station, this would reduce the risk for plant investors even more. One theory is that the scale economies afforded to bigger nukes may be diminished due to SMRs' modest size, offsetting any financial benefits they may have had in the past. The most advanced light water SMR model under development is a 60 MW reactors module developed by NuScale Power in the United States. On the basis of energy requirements, the architecture could provide up to 12 SMR elements to be cross within a primary pool of water, which would serve as both an absorber plate and a passively cooling unit. In September 2020, the NRC intends to finish its environmental safety assessment form and then release a finalized clearance draught, despite the lack of an official deadline.

In the mid-2020s, NuScale plans to start up its first 12-module facility. It will be constructed at Idaho Research Center using a mix of governmental and non-federal funding. The primary aspects of the NuScale plant, like those of previous SMR ideas, are intended to be production plant and transported to the production plant for assembly. Light water SMRs are presently being developed by companies in a number of nations. In contrast to NuScale, businesses like as Holtec, Westinghouse, as well as GE Hitachi are exploring this technology in the United States [12].

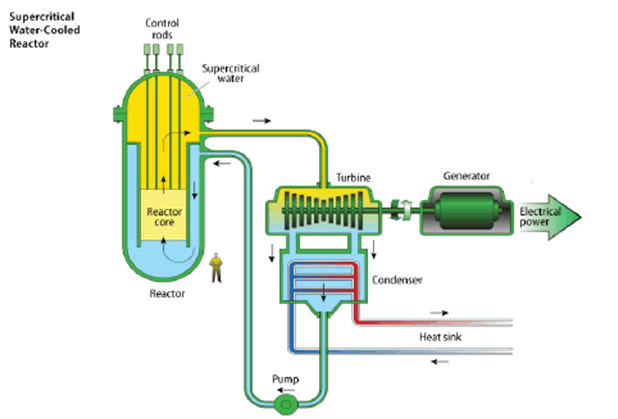

Supercritical water-cooled reactorModern LWR technique has been elevated in temperature by the SCWR. Because of this, SCWRs use extreme water, which has been warmed to a point where it can't be distinguished between its liquid and vapour phases, to maximize process efficiency. Figure 1 layout of Supercritical Water-Cooled Reactor.

Existing BWR reactor vessel pumps, vapor splitter, and washers would no longer be needed under the overheated conditions. Some sophisticated coal and gas-fired power stations have already utilized supercritical water to improve plant efficiency. SCWRs may be built to function in the fast or temperate neutron spectrums Figure 1.

There are two types i.e. high-temperature gas reactors and Gas-cooled fast reactors.

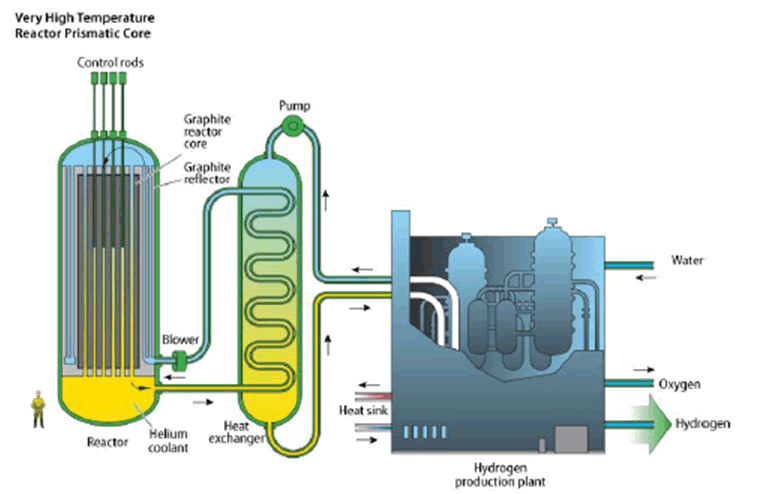

High temperature gas reactorsThis kind of thermal reactor is cooled with helium and moderated with graphite. In contrast to many existing reactors, they would have higher coolant output temperatures. This high thermal threshold makes it possible to provide heat for industry applications including cogeneration of power and gas. Prior RD programmes sought to achieve very high reactor outflow temperatures, whereas recent efforts have concentrated on breeder reactors with reduced power temperatures, based on the belief that reactors with reduced power temperature changes will be more financially sustainable in the near future [13].

There are basically two ways to go about designing this. Graphite blocks having removable sections are used in one, while snooker ball-sized graphene spheres or pebbles are used in the other, and both include fuel granules placed in the shape of a pebble bed. Firstly, the domains are retrieved from furnace's base, where they are inspected for burn up and then either returned to reactor cores walls or changed if no longer suitable for use in reactor. Many HTGRs include SMRs built inside.

Fuel for these reactors consists of poppies seed-sized products of combustion covered in silicon carbide and other high-temperature coatings as illustrated in Figure 2. When an accident occurs, the graphite moderator's large heat capacity means the reactors or its fuels must maintain the greatest possible core heat. So according HTGR proponents, even if active cooling mechanisms failed, the reactor's core just wouldn't melt or emit radioactive pollutants into the atmosphere Figure 2.

Among the advanced reactor ideas, HTGRs are one of the most technologically sophisticated. Several experimental as well as operational HTGRs have been constructed in a variety of nations since the 1960s. As of right now, construction is underway in China on a two-unit plug flow HTGR plant. The Energy Policy Act of 2005, which established the Next Generation Nuclear Plant (NGNP) programme, contributed to the emergence of High-Temperature Gas Reactors (HTGRs) mostly in United States.

The DOE awarded X-energy $53 million in 2016 for the development of a flexible trickle bed HTGR system. X-energy received the$10 million DOE agreement in 2018 for its services. X-energy is also collaborating with the Department of Energy and others to explore the fuel technology for an HTGR pebble bed reactor. Hybrid Power Technologies andHolosGen are two more U.S. firms working on HTGRs [14].

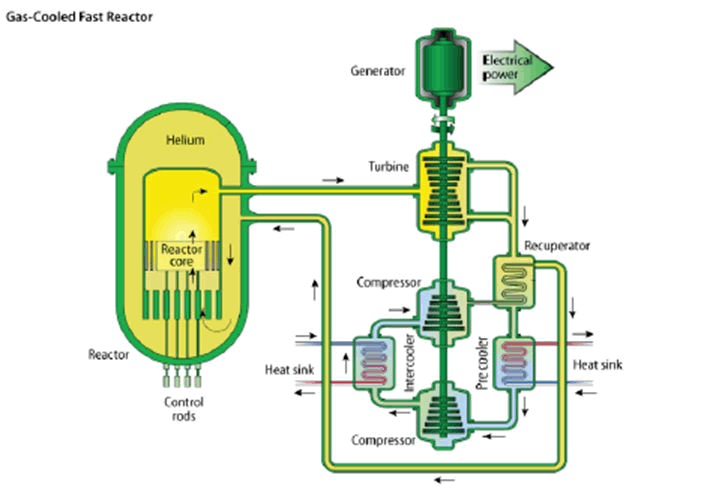

Gas-cooled fast reactorHelium is used as the primary coolant in Gas-Cooled Fast Reactors (GFRs), which are high-temperature, shuttered rapid reactors. The major difference here between HTGR and the GFR seems to be the neutron band. There would be no need to employ a big graphite absorber in HTGRs because of this. The GFR, if constructed as a breeder, would use a full U-Pu energy grid, in which spent fuel is recycled to produce a substantially increased supply of uranium and plutonium.

GFRs would be able to operate at temperatures similar to those of HTGRs, making them suitable for power generation as well as providing heating elements for industrial uses. When an accident occurs, the super-cooled liquid helium coolant's thermal transfer capability is reduced compared to that of molten material coolants like sodium and lead.

Prototype GFR development started in 2015, based mostly on French design. Ending the conceptual framework of the ALLEGRO reactor before 2025 was set as a goal by the band members, with construction starting after that. ALLEGRO will be the first presentation of a GFR if it will be successful, Figure 3.

Fusion reactorsLight atomic nuclei might be fused instead of heavier things in fusion reactors to produce energy. Significant RD investment, including around $20 billion on joint development finance, is being invested in France's nuclear research and development reactor. The United States seems to be a major donor to the project. Plasma is a type of substance where electrons are thrown out of nucleus of an atom by heating light atoms, typically hydrogen isotopes, to 100 million degrees Fahrenheit.

It's a huge technological problem to keep the plasma intact until its heated enough to start a fusion reaction. ITER would condense a particle of hydrogen using a strong magnetic field, whereas other methods would use lasers or other high-energy sources to compress a particle of hydrogen. No burning plasma has yet been produced by fusion reactions at the lab scale, where the power provided by fusion is now at least equal to the energy needed for heating plasma. The plasma in a fusion energy plant must be ignited using fusion energy before it can be used as a source of electricity. By the end of 2025, ITER should be able to produce its first plasma, with full operations starting by the year 2035, comprising plasma burning experiments [15].

Discussion

With the NGNP, the researchers hoped to demonstrate that HTGR technologies can provide both levels of power heat sources for a wide variety of industrial applications. As a result of the initiative, academia, commerce, and the US Nuclear Regulatory Commission (NRC) have been able to work together to do the research and development necessary to get a license and begin operating gas-cooled, occurrence reactors in the United States of America. Collaboration with foreign researchers was made possible via the Generation IV Foreign Conference Very High Temperature Experimental System Arrangement, and research and development on TRISO particles fuels, components, design methods, and application software has continued. A focus on efficiency and cost was placed on NGNP RD activities to ensure that the results were as useful as feasible. NGNP assimilation into many industrial applications was assessed in trade studies, and cost-sharing mechanisms were developed to assist industry in commercializing HTGR technology, which the Department started working with the commercial industry in the United States. A fundamental foundation for approving gas-cooled reactors in the US was created as a consequence of Department collaboration with the NRC.

Most of these activities are geared toward bettering scientific understanding of these technologies, building an international civilian nuclear RDD group, growing financial competitiveness, and lowering scientific and legal uncertainty and risk regarding the deployment of innovative nuclear plant innovations. These are the main goals. International collaboration is facilitated via bilateral and multilateral agreements, such as the Generation IV Global Conference. Advanced Reactor Concepts (ARC), Advanced Small Modular Reactor (aSMR) programmes and the Office of Advanced Reactor Technologies (ART) supports Research, Development And Deployment (RD&D) operations to advance the safety, technological, economic, and environmental significant advances of innovative Generation IV atomic energy technologies using Next Generation Nuclear Plant (NGNP). These advances will be pursued by the Department of Nuclear Energy (NE) via RDD efforts at DOE national labs and universities, and also cooperation with industry and foreign partners.

Conclusion

For a variety of reasons, such as a drop in sales or technological infancy, many future improved reactors will require competitively available fuels. Existing uranium fuels may be further enriched, as can new fuels currently being developed. Several advanced reactors will be unable to be deployed without rapid investment in fuel processing and manufacturing technology due to a lack of next-generation fuels. Advanced reactor projects may be more financially viable in the demonstration and operating stages if government agencies agree to purchase energy from them. They may provide a stable revenue stream that helps advanced nuclear projects get finance and perhaps lowers their financing costs.

If United States Congress authorizes it, federal agencies may provide above-market rates for electricity to promote the commercialization of nuclear technology. In conclusion, experts decided that the most sophisticated light water Small Modular Reactor (SMR) type is a 60 MW reactors module developed by NuScale Power in the United States. The designs were selected based on a number of factors, including reliability, sustainability, cost; security measures, proliferation resistance, and also waste minimization. The application of these technologies described in this article may begin by 2030 and thus are expected to reach commercialization by 2050.

References

- Clement C, Maliverney B, Mulet Marquis D, Sauvage JF, Blanchard MT, et al. (2008) Drafting and implementation of a'practical elimination'approach for gen IV nuclear reactors. In Proceedings 2008 Int Cong Adv Nuc Power Plants. [Crossref] [Google Scholar] [Pubmed]

- Hingsamer M, Jungmeier G (2019) role bioenergy bioeconomy. 179-222. [Crossref][Google Scholar] [Pubmed]

- Dai Z, Wang C, Zhang D, Tian W, Qiu S, et al. (2021) Design and analysis of a free-piston stirling engine for space nuclear power reactor. Nucl Eng Technol 53: 637-646 [Crossref][Google Scholar] [Pubmed]

- KuCC, Lee KY, Edwards RM, (1992) Improved Nuclear Reactor Temperature Control Using Diagonal Recurrent Neural Networks. IEEE Trans Nucl Sci 39: 2298-2308 [Crossref][Google Scholar][Pubmed]

- Hallonsten O, Kaiserfeld T (2020) Neutron sources. Between Making Knowing 553-560. [Crossref][Google Scholar][Pubmed]

- Zinkle SJ, Busby JT (2009) Structural materials for fission and fusion energy. Materials today. 12:12-1 [Crossref][Google Scholar] [Pubmed]

- Vadi R, Sepanloo K. (2016) An improved porous media model for nuclear reactor analysis. Nucl Sci Tech 27 :1-24 [Crossref][Google Scholar][Pubmed]

- Seo SB, Kim IG, Kim KM, Jeong YS, Bang IC, et al. (2018) Risk mitigation strategy by passive IN-core cooling system for advanced nuclear reactors. Ann Nuc Ener 111: 554-5 [Crossref][Google Scholar] [Pubmed]

- Lee J, Park GC, Cho HK (2015) Improvement of cupid code for simulating filmwise steam condensation in the presence of noncondensable gases. Nucl Eng Technol 47: 567-578. [Crossref][Google Scholar][Pubmed]

- Allen T, Busby J, Meyer M, Petti D (2010) Materials challenges for nuclear systems. Materials Today 13: 14-23. [Crossref][Google Scholar][Pubmed]

- Alam F, Sarkar R, Chowdhury H (2019) Nuclear power plants in emerging economies and human resource development: A review. Energy Procedia 160: 3-10. [Crossref][Google Scholar][Pubmed]

- Zinkle S J, Was GS (2013) Materials challenges in nuclear energy. Acta Mater 61: 735-58. [Crossref][Google Scholar][Pubmed]

- Xing J, Song D, Wu Y (2016) HPR1000: Advanced Pressurized Water Reactor with Active and Passive Safety. Eng 2: 79-87

[Crossref] [Google Scholar][Pubmed]

- Penner SS, Seiser R, Schultz KR (2008) Steps toward passively safe, proliferation-resistant nuclear power. Prog Ener Combust Sci 2: 79-87. [Crossref][Google Scholar] [Pubmed]

- Bernstein LA, Brown DA, Koning AJ, Rearden BT, Romano CE, et al. (2019) Our future nuclear data needs. Annu Rev Nucl Part Sci 69: 109-1 [Crossref][Google Scholar][Pubmed]

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi