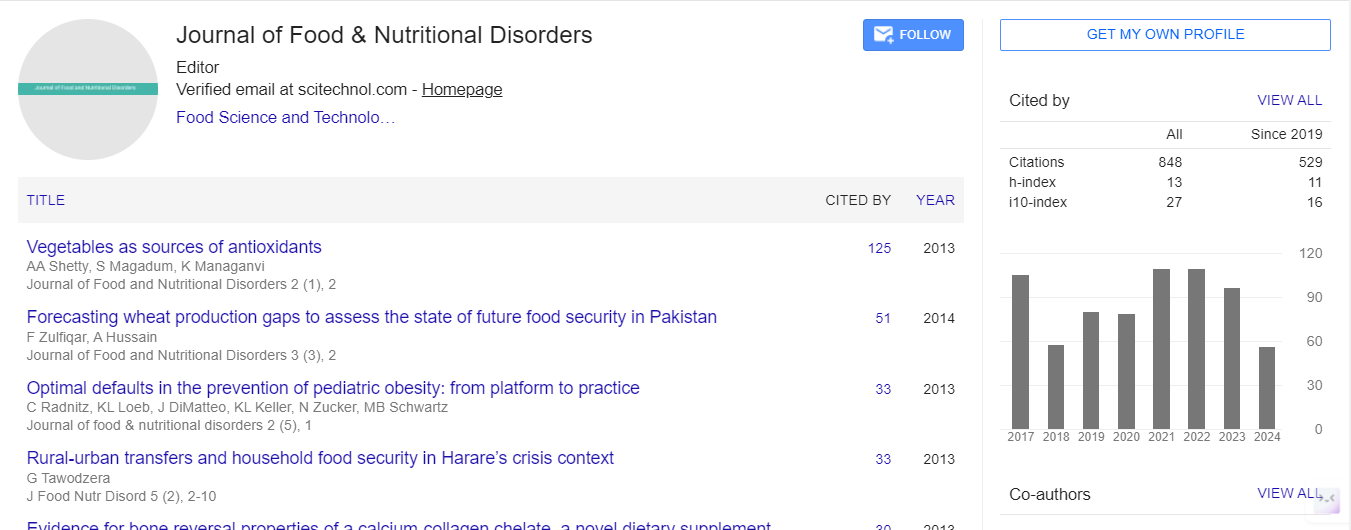

Research Article, J Food Nutr Disor Vol: 5 Issue: 1

Influence of Season and Storage Period of Camel Meat on the Quality Characteristics of Burger

| Suliman AME1, Fadlalmola SA2, Babiker ASA2, Yousif HS2, Ibrahim SM3, Abdelrahim YM3 and Arabi OA3 | |

| 1Department of Biology, University of Hail, Kingdom of Saudi Arabia | |

| 2Department of Veterinary science, University of Butana, Sudan | |

| 3Department of engineering and Technology, University of Gezira, Sudan | |

| Corresponding author : Abdel Moneim Elhad Suliman Department of Biology, University of Hail, Kingdom of Saudi Arabia, Tel: 966538081679 E-mail: abuelhadi@hotmail.com |

|

| Received: October 12, 2015 Accepted: January 14, 2016 Published: January 20, 2016 | |

| Citation: Suliman AME, Fadlalmola SA, Babiker ASA, Yousif HS, Ibrahim SM, et al. (2016) Influence of Season and Storage Period of Camel Meat on the Quality Characteristics of Burger. J Food Nutr Disor 5:1. doi:10.4172/2324-9323.1000190 |

Abstract

Influence of Season and Storage Period of Camel Meat on the Quality Characteristics of Burger

The present study was conducted to investigate the influence of season and storage period on camel meat product burger. Fresh camel meat samples were obtained from slaughter house and stored at -18°C for 3, 6 and 9 months (summer, winter and autumn seasons). Burger samples were prepared at the end of each storage period. Manufactured Burgers were subjected to physicochemical, microbiological and sensorial analyses. The results revealed significant interaction between the season and storage time. Oxidative rancidity of burger were significantly (P<0.05) affected by the storage time. Burger lightness (L), redness (a) and yellowness (b) were affected significantly with increasing storage time.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi