Research Article, J Food Nutr Disord Vol: 6 Issue: 2

Optimization of the Technology of Chlorogenic Acid Extraction from Yacon (Smallanthus Sonchifolius) using Box-Behnken Design

Songshan Qiu*, Cuicui Jiang, Yao Huang and Rujin Zhou

Development Center of Technology for Fruit & Vegetable Storage and Processing Engineering, Guangdong University of Petrochemical Technology, Guangdong Maoming 525000, China

Corresponding author : Songshan Qiu

Development Center of Technology for Fruit & Vegetable Storage and Processing Engineering, Guangdong University of Petrochemical Technology, Guangdong Maoming 525000, China

Tel: 86 668 292 3508

E-mail: tustqss@163.com

Received: April 11, 2017 Accepted: April 17, 2017 Published: April 21, 2017

Citation: Qiu S, Jiang J, Huang Y, Zhou R (2017) Optimization of the Technology of Chlorogenic Acid Extraction from Yacon (Smallanthus Sonchifolius) using Box-Behnken Design. J Food Nutr Disord 6:2. doi: 10.4172/2324-9323.1000223

Abstract

Optimization of the Technology of Chlorogenic Acid Extraction from Yacon (Smallanthus Sonchifolius) using Box-Behnken Design

In order to further enhance the value of comprehensive utilization, soxhlet extraction of chlorogenic acid (CGA) from yacon was studied in this paper. Firstly, single factor experiment provided the extraction effects of three main parameters of soxhlet extraction process involving syphon time, ethanol concentration and liquid-solid rate and obtained preliminary process parameters for higher extraction rate; furthermore, Box-Behnken design was applied to obtain the three optimal parameters of extraction process and formulate a regression model fitting process parameters and extraction rate. Results showed that the optimal soxhlet extraction process was as follows: syphon times of 5, ethanol concentration of 50% and liquid-solid rate of 15 mL/g, and the predicted extraction rate was 5.21%. In the optimal process actual extraction rate was 5.22%, which accorded well with the predicted value of the model. The analysis of regression model revealed that the effect of syphon time, ethanol concentration and liquid-solid rate each other was significant, especially the interaction of ethanol concentration and liquid-solid rate was extremely significant. To sum up, response surface methodology can be applied to the optimization of soxhlet extraction process of CGA in yacon, and the optimal soxhlet extraction process is advisable to extract CGA in yanco with high extraction rate and further to enlighten industry production and market-oriented utilization of CGA.

Keywords: Yanco; Chlorogenic acid (CGA); Soxhlet extraction; Box- Behnken design

Introduction

Yacon is a species of perennial daisy originally grown in South America, which has strong adaptation capacity and resistance to strong light and low temperature [1]. The tuber of yacon contains quantities of fructo-oligofructose and protein, and its functional active compound is diverse and abundant such as amino acid, flavonoid and polyphenols [2]. Chlorogenic acid (CGA) is a depside consisting of caffeic acid (CA) and quinic acid (QA) [3,4]. CGA has strong capacity to scavenge free radicals and antioxidant activity [5,6], hence it is extensively applied to the medicine, food and daily cosmetics industries. Currently, there are many extraction methods used for, such as water extraction, organic solvent extraction [7] and enzymolysis extraction [8]. Meanwhile, ultrasonic and microwave are often coupled with conventional extraction method, which is evident to upgrade extraction efficiency [9,10]. Additionally, ultrahigh pressure extraction [11], supercritical fluid extraction [12], reverse micellar solution extraction [13] and other novel advanced extraction technologies are also available in the extraction of CGA. Novel extraction technologies of CGA have the feature of high efficiency; however, they are deficient with complicated operation, high energy consuming and high demand for equipment. While soxhlet extraction is featured with good choice, low energy consuming, simple operation and high extraction rate [14]. Currently, soxhlet extraction is extensively applied to many natural products. However, the technology parameters of soxhlet extraction of CGA are less reported, so that a soxhlet extractor was used to extract CGA from yacon using Box-Behnken design.

Materials and Methods

Materials

Yacon was provided by Gaozhou Fengsheng Food Co., LTD. in China, which was transported into the laboratory at its harvest and stored for use. Ethanol was analytic reagent, produced by Tianjin Baishi Chemical Industry Co. LTD. in China.

All determinations were carried out in triplicate and significant differences (p<0.05) were calculated using Duncan’s multiple range test.

Soxhlet extraction

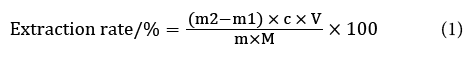

Dried yacon was broken down into powder, the powder of samples was put into a filtration paper cylinder in a soxhlet extractor, purchased from Shenzhen Kexin Glass Instrument Co. LTD. Secondly, the whole experiment apparatus was assembled together and some glass beads were added in flat bottom flask to avoid bumping. Next then, 50~250 mL ethanol solution was weighed and taken into the soxhlet extractor to carry out soxhlet extraction. At the end of soxhlet extraction, flat bottom flask was evaporated at 50~55°C in a rotary extractor, RE-52 rotary evaporator was provided by Shanghai Yahua Biochemical Instrument Factory, to remove residual water and ethanol, and dried at 60°C for 30 min to completely wipe up the influence of impurity such as water and ethanol. Eventually, the extracts were kept constant volume of precise 100 mL in a 100 mL volumetric flask and test its absorbance in the wave length of 330 nm using UV-3100PC USVIS spectrophotometer, purchased from Shanghai Meipuda Instrument Co. LTD. The extraction rate of CGA was obtained according to the computation equation (1).

In the equation (1), c was certain concentration (μg/mL) of CA corresponding to the absorbance of CA sample in the standard curve, m2 was the final mass (g) of the flat bottom flask and extraction, m1 was the mass (g) of flat bottom flask, V represented the volume (100 mL) of prepared testing solution of CA extraction, M was the sample mass (g) of yacon and m was the mass of taken CA extraction to prepare testing solution.

Formulation of standard curve of CA

Standard sample of CA was weighed 10 mg and precisely in 100 mL volumetric flask with absolute ethanol. Then sample solution was taken 0~6 mL to prepare 7 testing groups which were in 0~24 μg/mL. The testing groups were tested in the wave length of 330 nm to obtain their absorbances, and then a standard curve of CA was drawn where the absorbance of y coordinate axis responded to the CA concentration of x coordinate axis. The equation of standard curve was y=0.0382x +0.124, R2=0.9996.

Single factor experiment

Single factor experiment was carried out to explore the effect of syphon time, ethanol concentration and liquid-solid rate on extraction rate of CGA. In single factor experiment, the levels of syphon time were 1, 2, 3, 4, 5 and 6, the levels of ethanol concentration were 10%, 30%, 50%, 70% and 90%, and the levels of liquid-solid rate were 5, 10, 15, 20 and 25 mL/g, respectively.

Optimization of the technology using box-behnken design

According to single factor experiment, a Box-Behnken experimental of 3-factor and 3 levels were devised and carried out to optimize extraction parameters such as syphon time, ethanol concentration and liquid-solid rate in 3 levels, respectively, in which extraction rate of CGA responded to extraction parameters (Table 1).

| Factor | X1 (Syphon time) | X2 (ethanol concentration)/% | X3 (liquid-solid rate)/ (mL/g) |

|---|---|---|---|

| -1 | 4 | 40 | 10 |

| 0 | 5 | 50 | 15 |

| 1 | 6 | 60 | 20 |

Table 1: The factors and levels of experiments.

Data processing

Each group was repeated 3 times and average value was available. In single factor experiment, the effect of soxhlet extraction technology was drawn out; technology optimization by response surface design was in the overall assistance of Design-Expert soft including experimental design, data analysis, building model and technology optimization.

Results and Analysis

Single factor experiment of CGA extraction

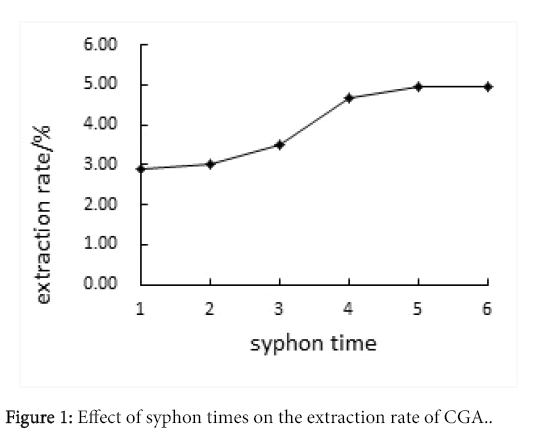

Effect of syphon times on the extraction rate of CGA: In the condition of 50% ethanol concentration and 15 mL/g liquid-solid rate, the effect of different syhon times on the extraction rate was shown in Figure 1. The extraction rate of CGA increased with the increasing of syphon time, the change of extraction rate was evident when syphon time was in 2~4, and the extraction rate reached the top of 5.03% in 5~6 syphons. Hence, the optimal syphon times were 5 times.

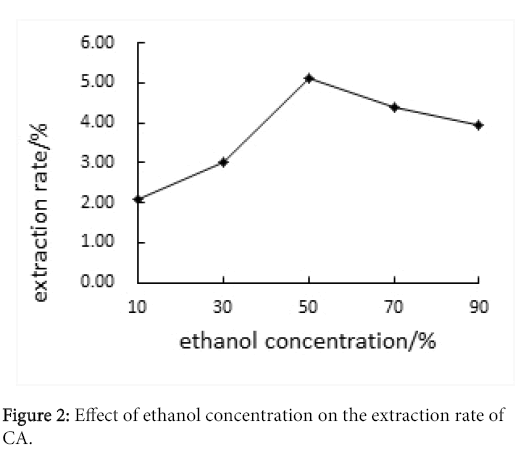

Effect of ethanol concentration on the extraction rate of CGA: In the condition of 5 syphons and 15 mL/g, the effect of ethanol concentration was shown in Figure 2. When ethanol concentration increased, the extraction rate firstly increased and then began to decrease at the arrival of the peak. When ethanol concentration was 50%, the extraction rate was the highest of 5.06%. The reason for this may be that extreme ethanol concentration led to the dissolution of massive alcohol soluble substance and CGA in yacon on contrast was not that easy to be extracted by high ethanol concentration, which both led to the decreasing of extraction rate of CGA. The optimal ethanol concentration was 50%, that ethanol concentration was higher was not always better

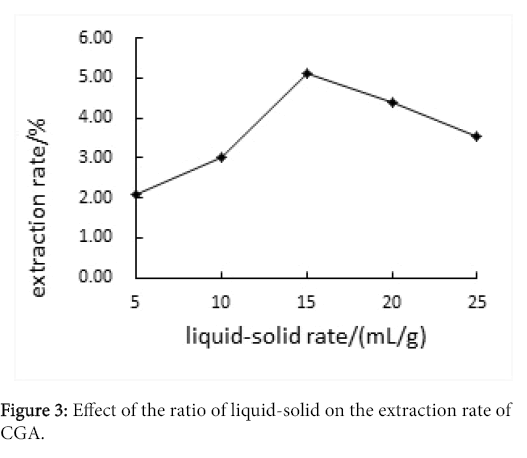

Effect of liquid-solid rate on the extraction rate of CGA: In the condition of 5 syphons and 50% ethanol concentration, the effect of liquid-solid rate was shown in Figure 3. The extraction rate was lowest when liquid-solid rate was 5 mL/g, increasing to 15 mL/g made the extraction rate reach the top of 5.00%, and then the extraction rate began to decrease. The reason for this may be that liquid-solid rate had positive effect on the mass transfer driving force, but if liquid-solid rate was extremely high solution temperature was lower, which decreased solute diffusion and extraction rate. Hence, that liquid-solid rate was higher was not always better, the optimal liquid-solid rate was 15 mL/g. Single factor experiment was carried out to change syphon time, ethanol concentration and liquid-solid rate, and preliminary conclusion was obtained that syphon time of 5, ethanol concentration of 50% and liquid-solid rate of 15 mL/g were the optimal technology parameters of soxhlet extraction of CGA.

Extraction optimization of CGA using box-behnken design

The response surface methodology (RSM) is in essence a statistical methodology absorbing many advantages of mathematical procedures that can be used to study the relationship between one or more responses and a number of independent variables. In addition to analyzing the effect of independent variables, the optimization methodology generates a mathematical model that accurately describes the overall process that response value responds to the change of independent variables [15]. Statistical optimization not only allows quick screening of large experimental domain, but also reflects the role of each of the components. RSM has already been successfully applied in extraction optimization of many natural active compounds such as total carotenoids [16] and antioxidant compounds [17]. Design-Expert soft presented a response surface design of 3-factor and 3-level, and the optimization of soxhlet extraction of CGA was carried out according to the design. The experimental combinations and their data of extraction rate were listed out in Table 2.

| Factor | X1(Syphon time) | X2 (ethanol concentration)/% | X3(Liquid-solid rate)/(mL/g) | Y (extraction rate)/% |

|---|---|---|---|---|

| 1 | 4 | 40 | 15 | 3.67 |

| 2 | 6 | 40 | 15 | 4.48 |

| 3 | 4 | 60 | 15 | 3.77 |

| 4 | 6 | 60 | 15 | 4.38 |

| 5 | 4 | 50 | 10 | 3.60 |

| 6 | 6 | 50 | 10 | 4.12 |

| 7 | 4 | 50 | 20 | 3.50 |

| 8 | 6 | 50 | 20 | 4.23 |

| 9 | 5 | 40 | 10 | 3.41 |

| 10 | 5 | 40 | 10 | 4.12 |

| 11 | 5 | 60 | 20 | 4.02 |

| 12 | 5 | 60 | 20 | 4.35 |

| 13 | 5 | 50 | 15 | 5.15 |

| 14 | 5 | 50 | 15 | 5.15 |

| 15 | 5 | 50 | 15 | 5.15 |

Table 2: The project and extraction rate of response surface methodology experiment.

Design-Expert soft was used to carry out regression analysis and present a regression equation which was Y=-36.55875+5.14708X1+0.73858X2+1.27525X3-0.00500X1X2+0.0105 0X1X3-0.006900X2X3-0.47208X1 2-0.00610X2 2-0.032883X32.

The significance test was also carried out in Table 3. In testing results, Pmodel was lower than 0.0001 and Plack of fit was 0.0754, indicating that the difference between actual value and academic value was insignificant. R2 was equal to 99.88%, indicating that the model could really reflect the effect of syphon time, ethanol concentration and liquid-solid rate on the extraction rate.

| Resource | Sum of square | Freedom degree | Mean square | F value | Prob>F | Siginificant |

|---|---|---|---|---|---|---|

| Model | 5.51 | 9 | 0.61 | 408.30 | <0.0001 | ** |

| X1 | 0.89 | 1 | 0.89 | 594.74 | <0.0001 | ** |

| X2 | 2.000E-004 | 1 | 2.000E-004 | 0.13 | 0.7298 | |

| X3 | 0.003 | 1 | 0.003 | 1.88 | 0.2290 | |

| X1X2 | 0.01 | 1 | 0.01 | 6.67 | 0.0492 | * |

| X1X3 | 0.011 | 1 | 0.011 | 7.36 | 0.0421 | * |

| X2X3 | 0.48 | 1 | 0.48 | 317.75 | <0.0001 | ** |

| X12 | 0.82 | 1 | 5.82 | 549.20 | <0.0001 | ** |

| X22 | 1.37 | 1 | 1.37 | 915.71 | <0.0001 | ** |

| X32 | 2.50 | 1 | 2.50 | 1665.41 | <0.0001 | ** |

| Residual error | 0.007 | 5 | 0.001 | |||

| Lack of fit | 0.007 | 3 | 0.002 | 74.25 | 0.0754 | |

| Pure error | 6.667E-005 | 2 | 3.333E-005 | |||

| Total error | 5.51 | 14 |

R2=99.88%

Notice: *meant significant (Prob<0.05), **meant extremely significant (Prob<0.01).

Table 3: Analysis results of variance of the experiment.

The significance test also revealed that syphon time had significant interaction on the extraction rate with ethanol concentration and liquid-solid rate respectively; furthermore, the interaction of ethanol concentration and liquid-solid rate was extremely significant. The response surface plots reflecting the interactions of syphon times, ethanol concentration and liquid-solid rate each other were shown in Figure 3. In Figure 3, extraction rate firstly increased and then kept steady with the increasing of syphon times in certain ethanol concentration and liquid-solid rate. In different conditions of ethanol concentration and liquid-solid rate, the effect of syphon times changed a lot. Meanwhile, extraction rate firstly increased and then decreased with the increasing of ethanol concentration in certain syphon time and liquid-solid rate and, effect of ethanol concentration changed a lot in different conditions of syphon time and liquid-solid rate. In the same way, extraction rate firstly increased and then decreased with the increasing of liquid-solid rate in certain syphon times and ethanol concentration, the effect of liquid-solid rate also changed a lot in different conditions of syphon times and ethanol concentration Figure 4.

According to the model, Design-Expert soft presented the optimal extraction parameters of soxhlet extraction. When Y was the highest, X1 was equal to 5.32, X2 was 50.41 and X3 was 15.33, in another word, syphon time should be 5.32, ethanol concentration should be 50.41% and liquid-solid rate should be 15.33 mL/g, in the condition the extraction rate was the highest of 5.21%. For the convenience, syphon time was 5, ethanol concentration was 50.41% and liquid-solid rate was set 15.33 mL/g, which were as the optimal extraction condition. In order to verify the precise, 3 verification experiments were carried out in the optimal condition and the extraction rate values were 5.22%, 5.21% and 5.23%, whose average value of 5.22% was close to the academic value. Hence, response surface methodology was feasible to optimize soxhlet extraction of CGA; the optimal extraction technology was valuable in actual application.

Discussion

As a a physiological active compound of phenylpropanoids in many plants formulating through shikimic acid pathway in the process of aerobic respiration, chlorogenic acid (CGA) is increasingly marching into daily chemical and food industries. Current study has used many extraction technologies to get CGA, but soxhlet extraction is less applied to extract CGA. Traditional technology spends much time and vitality, and its extraction rate is low, while novel advanced technology is faced with complicated operation, high demand for instrument and high cost. Compared with technologies above, soxhlet extraction in the study is universally applied that takes advantage of solvent reflux and siphon principle to make solid extracted constantly by pure solution, soxhlet extraction has good choice, low energy consumption and high extraction rate. Hence, Chlorogenic acid in yacon was extracted by soxhlet extraction; the influence and optimal condition of extraction technology were explored. Soxnlet extraction was determined that its optimal extraction technology by response surface methodology included syphon time of 5, ethanol concentration of 5 and liquid-solid rate of 15.33 mL/g, and the extraction rate was 5.21%, which was evidently higher than the extraction rate [11] of yacon CGA in ethanol/salt aqueous two-phase system and similar with the extraction rate of CA using ultrasonic assistance extraction [13]. Hence, it was simple and efficient to extract CGA using soxhlet extraction, and it could support something valuable to learn for the development of Chlorogenic acid in yacon.

Conclusion

Chlorogenic acid (CGA) is a physiological active compound of phenylpropanoids in many plants formulating through shikimic acid pathway in the process of aerobic respiration, which was proved evident medicine value and medical care function. In the study, Chlorogenic acid (CGA) in yacon was extracted by soxhlet extraction, single factor experiment and response surface design was in assistance to construct secondary multiple regression equation where extraction rate responded to extraction parameters.

Y=-36.55875+5.14708X1+0.73858X2+1.27525X3-0.00500X1X2+0.01 050X1X3-0.006900X2X3-0.47208X1 2-0.00610X2 2-0.032883X3 2. Soxnlet extraction was determined that its optimal extraction technology included syphon time of 5, ethanol concentration of 50.41% and liquid-solid rate of 15.33 mL/g, and the extraction rate was 5.21% which had little error of 0.01% with actual value of verification experiment. Hence, response surface methodology could apply to the optimization of soxhlet extraction of Chlorogenic acid (CGA) in yacon, obtained model was reliable and extraction rate in the optimal technology was high. Meanwhile, ethanol concentration and liquidsolid rate were extremely significant to affect extraction rate, the interaction of syphon time and ethanol concentration was significant and that of syphon liquid-solid rate was also significant.

Acknowledgment

This research was financially supported in part by Science and Technology Project Program of Guangdong Province.

References

- Franco TS, Perussello CA, Ellendersen LN (2016) Effects of foam mat drying on physicochemical and microstructural properties of yacon juice powder. LWT - Food Sci Technol 66: 503-513.

- Sousa S, Pinto J, Rodrigues C, Maria G, Claudia P, et al. (2015) Antioxidant properties of sterilized yacon (Smallanthus sonchifolius) tuber flour. Food Chem 188: 504-509.

- Liu B, Dong B, Yuan X, Kuang Q, Zhao Q, et al. (2016) Enrichment and separation of chlorogenic acid from the extract of Eupatorium adenophorum Spreng by macroporous resin. J Chromatograph B 1008: 58-64.

- Lozano-Vazquez G, Lobato-Calleros C, Escalona-Buendia H, Chavez G, Alvarez-Ramirez J, et al. (2015) Effect of the weight ratio of alginate-modified tapioca starch on the physicochemical properties and release kinetics of chlorogenic acid containing beads. Food Hydrocolloid 48: 301-311.

- Wang Y, Li Z, Li J, Duan YF, Niu J, et al. (2015) Effects of dietary chlorogenic acid on growth performance, antioxidant capacity of white shrimp Litopenaeus vannamei under normal condition and combined stress of low-salinity and nitrite. Fish & Shellfish Immunol 43: 337-345.

- Xi Y, Fan X, Zhao H, Jiang W (2017) Postharvest fruit quality and antioxidants of nectarine fruit as influenced by chlorogenic acid. LWT-Food Sci Technol 75: 537-544.

- Tan Z, Wang C, Yi Y, Wang H, Li M, et al. (2014) Extraction and purification of chlorogenic acid from ramie (Boehmeria nivea L. Gaud) leaf using an ethanol/salt aqueous two-phase system. Sep Purif Technol 132: 396-400.

- Miura C, Li H, Matsunaga H, Haginaka J (2015) Molecularly imprinted polymer for chlorogenic acid by modified precipitation polymerization and its application to extraction ofchlorogenic acid from Eucommia ulmodies leaves. J Pharm Biomed Anal 114: 139-144.

- Martin Tongai M, Ying Y, Zhi-qin C, Ying Z, et al. (2012) Optimization and orthogonal design of an ultrasonic-assisted aqueous extraction process for extracting chlorogenic acid from dry tobacco leaves. Chin J Nat Med 10: 311-320.

- Belwal T, Bhatt ID, Rawal RS (2017) Microwave-assisted extraction (MAE) conditions using polynomial design for improving antioxidant phytochemicals in Berberis asiatica Roxb ex DC leaves. Ind Crops Prod 95: 393-403.

- Hu W, Guo T, Jiang WJ, Dong GL, Chen DW, et al. (2015) Effects of ultrahigh pressure extraction on yield and antioxidant activity of chlorogenic acid and cynaroside extracted from flower buds of Lonicera japonica. Chin J Nat Med 13: 445-453.

- Paula JT, Aguiar AC, Sousa IMO, Cabral FA (2016) Scale-up study of supercritical fluid extraction process for Baccharis dracunculifolia. J Supercrit Fluids 107: 219-225.

- Saleh IA, Vinatoru M, Mason TJ, Abdel-Azim NS, Aboutabl EA, et al. (2016) A possible general mechanism for ultrasound-assisted extraction (UAE) suggested from the results of UAE of chlorogenic acidfrom Cynara scolymus L. (artichoke) leaves. Ultrason Sonochem 31: 330-336.

- Ramluckan K, Moodley KG, Bux F (2014) An evaluation of the efficacy of using selected solvents for the extraction of lipids from algal biomass by the soxhlet extraction method. Fuel 116: 103-108.

- Shahid M, Zhou Y, Ren-Cheng T, Chen G, Wani WA (2017) Colourful and antioxidant silk with chlorogenic acid: Process development and optimization by central composite design. Dyes Pigm 138:30-38.

- Jovanovic A, Dordevic VB, Zdunic GM, Branko B (2017) Optimization of the extraction process of polyphenols from Thymus serpyllum L. herb using maceration, heat-and ultrasound-assisted techniques. Sep Purif Technol 179: 369-380.

- Espada-Bellido E, Ferreiro-Gonzalez M, Carrera C, Palma M, Barroso CG, et al. (2017) Optimization of the ultrasound-assisted extraction of anthocyanins and total phenolic compounds in mulberry (Morus nigra) pulp. Food Chem 219:23-32.

Spanish

Spanish  Chinese

Chinese  Russian

Russian  German

German  French

French  Japanese

Japanese  Portuguese

Portuguese  Hindi

Hindi